- 13 -

CZ sincro

DG83 D

The unit can be used as a stroboscopic RPM counter for measuring at a

distance and without any reflectors, RPM on Diesel and petrol engines and of

any rotating parts, where it is not possible to pick up any synchronizing

signals.

7.1 With the engine stopped, trace with a white chalk a reference line on

the pulley or other rotating parts. Press key

RESET

to set the RPM

measurement and immediately after press key

2

4

. Release key

RESET

and keep key pressed until number

60 60

60 60

60

appears on display 1.

The timing light will flash automatically.

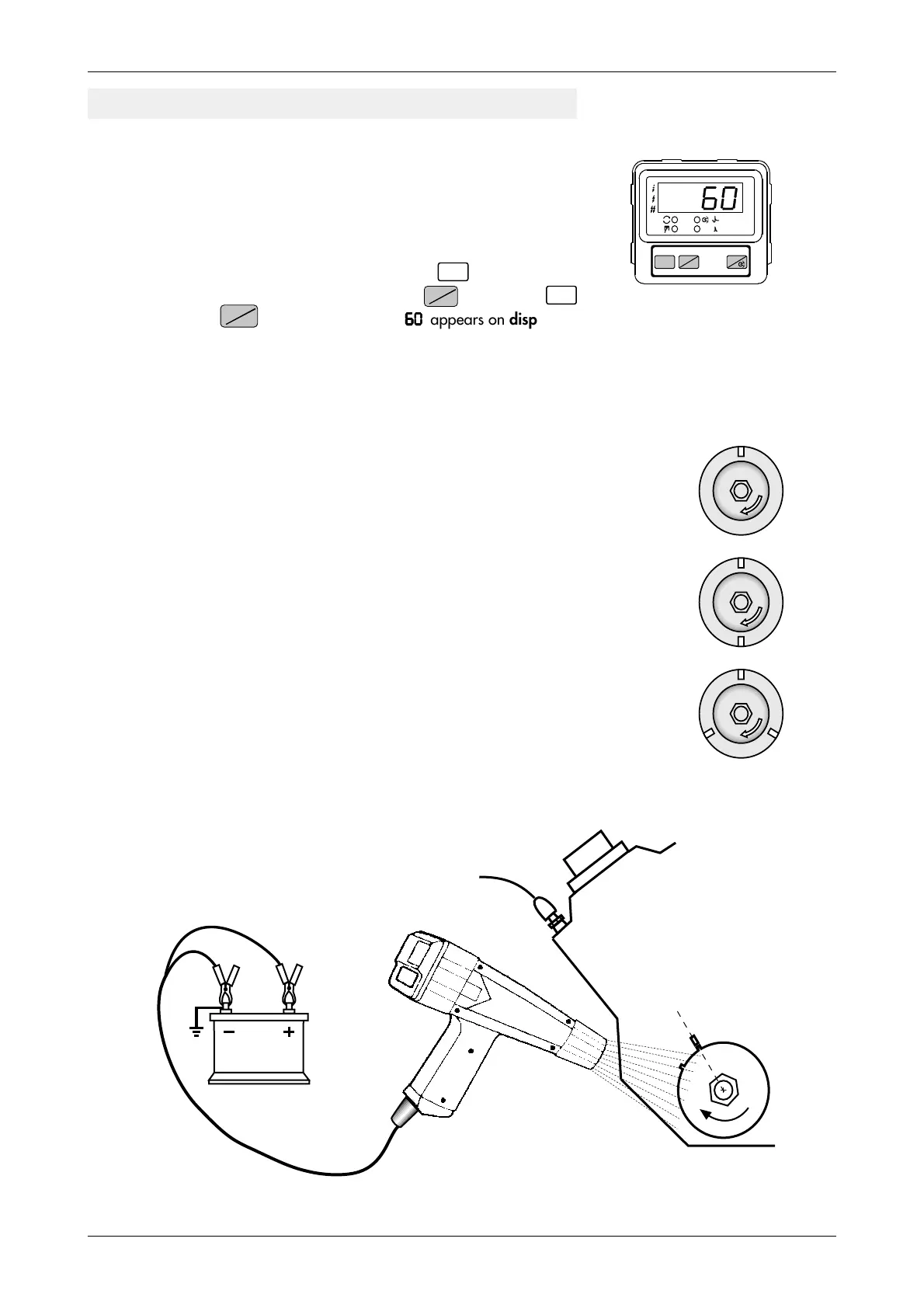

7.2 Through key C + /– set the RPM number on display 1 as close as

possible to the engine speed estimated. Direct the flash towards the

pulley and increase or decrease the RPM number displayed until the

pulley rotation seems progressively slowing. The correct RPM is reached

when the pulley appears still.

NOTE

The pulley could appear still even when the flash frequency is half,

double or triple of the real RPM. In these latest 2 cases, the traced line

would appear as shown in Fig. 19.

A halved frequency would cause a wrong rotation speed.

At engine speeds between 4500 ÷ 6000 RPM, use the stroboscope for

3 ÷ 5 minutes with 1 minute interval to avoid overheating.

Fig. 20

TDC

Fig. 19

12 V

Black

Red

Fig. 18

FLASHING FREQUENCY AND

VIEWING OF MARKS

ON THE PULLEY

A ) Correct

frequency

B )Double

frequency

C ) Triple

frequency

7.0 STROBOSCOPIC RPM COUNTER

STROBOSCOPIC RPM MEASUREMENT

V

2

4

RESET

STROBOTESTER DG 83- D

min.

V=

2

4

Loading...

Loading...