- 7 -

CZ sincro

DG83 D

NOTE

In case the unit should not blink regularly, check:

• Against the light that the inductive clamp’s cores match; remove possible

dirtiness with a clean wiper.

• That the clamp’s arrow is pointing towards the opposite direction of the

spark-plug in points systems.

• That coil leads are not reversed

• Reversed polarity voltage in DIS systems (reverse the clamp with the

arrow poiting to the opposite direction of the spark-plug).

• Discharges between cap poles or to ground due to dirtiness or moisture

• Leakages to earth or between cables due to ageing or cracks in the

cable covering.

• Wear or excessive gap between central contact and rotor arm or

between rotor arm and poles or the distributor cap.

• Too low voltage on the spark-plug due to faults in the ignition system.

• Timing light too near to spark cables, distributor or ignition coil.

• Cable or interference suppressor with a too high or interrupted

resistance.

ATTENTION

• Some engines seem equipped with coil per plug system but they actually

are DIS systems (eg.: Peugeot 206, 306, ecc.). In this case connect the

inductive clamp to the cable connected to the coil's negative (–) pole

relevant to cyl. 1 - 2 (Fig. 9) and select 1 spark per revolution.

• Some motorbikes have special ignition systems with two sparks per

revolution. Doubled reading values appear if setting is not correct.

• Malfunctions in IAW MARELLI systems can be due to wrong distributor’s

position.

• For correct advance readings in points sytems, adjust the distributor’s

position. If the centrifugal advance does not correspond, check the

centrifugal expansion mechanism and the diaphragm of the vacuum

cap.

In case no advance variation is verified when connecting the cap tube,

check the diaphragm and the pivot of the baseplate.

• In points systems, advance differences between cylinders can be caused

by a different cam wear. Check that Dwell differences are within 3

degrees by connecting the inductive clamp to the spark cable of each

cylinder.

• Advance on vehicles equipped with engine management ECUs depends

on the processing of signals from different sensors.

It is possible to make advance checks in different conditions only if

comparison data are available.

In case differences should be found, it is necessary to check engine

temperature sensors or other causes that can influence advance

mapping.

• Should the initial advance correspond to the value stated by the

Manufacturer, and should the engine have cranking problems, check

that the distribution belt has not jumped a cog.

• Should you use a separate battery, connect the negative pole to the

engine ground.

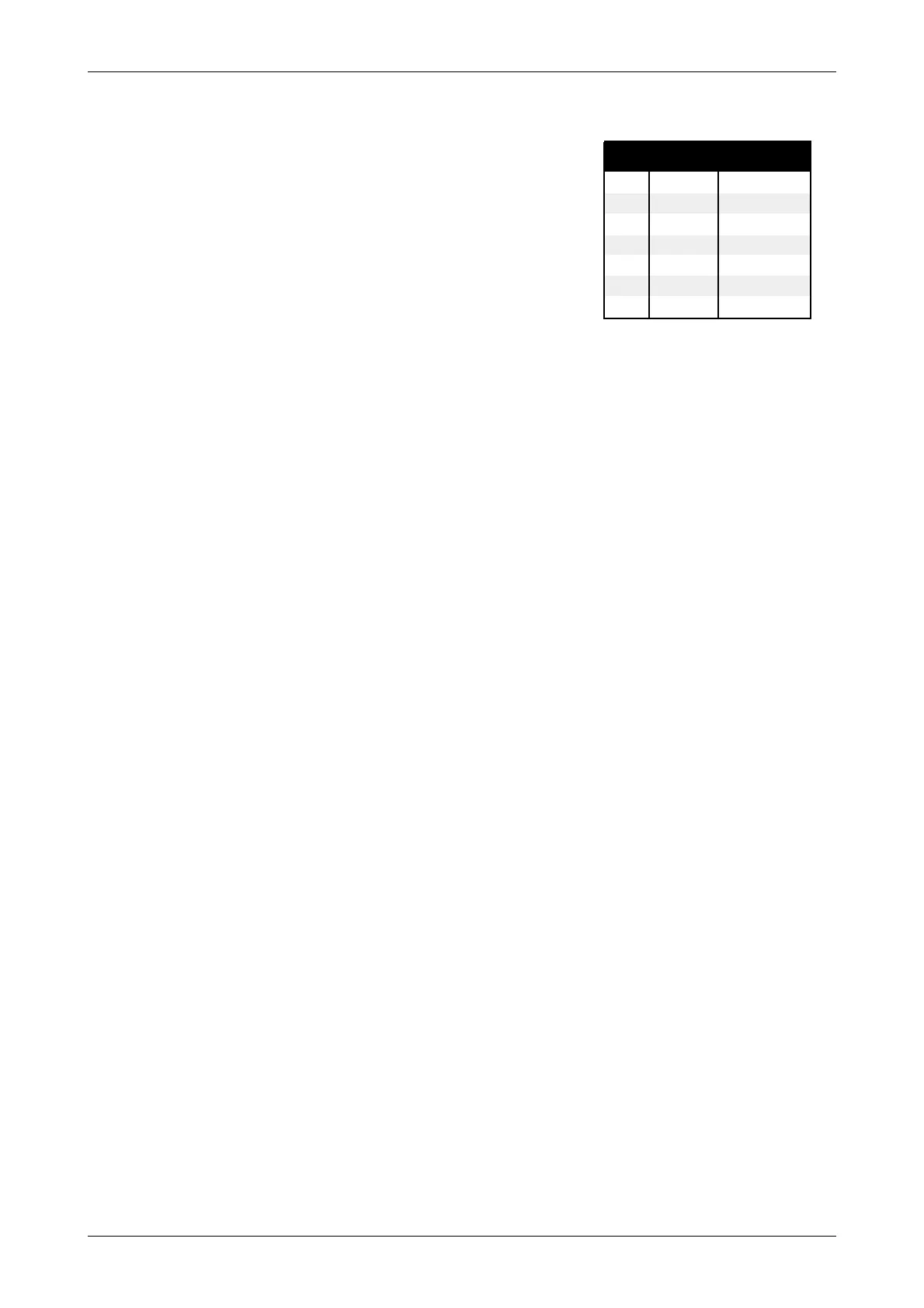

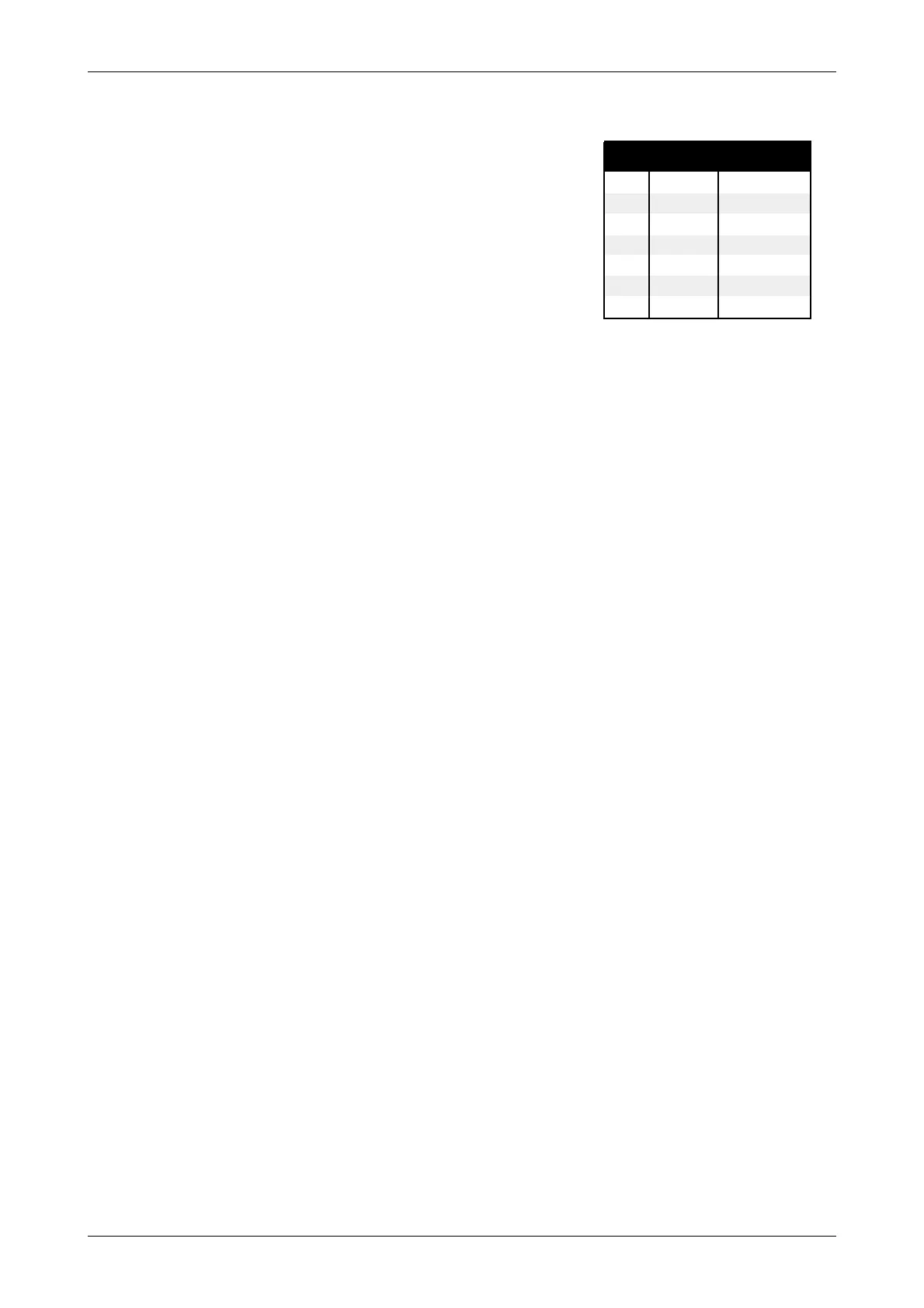

Strokes System Spark/rev

4 Distrib. 1 every 2 revs

4 Coil per 1 every 2 revs

plug

4 D.I.S. 1 per rev.

2 Coil per 1 per rev.

plug

2 D.I.S. 2 per rev. *

Table.1:

*) Special systems. Set the

Strobotester as described in chapt.

8.2

NOTE

After connection to battery, the

Strobotester sets for 1 spark per 2

revs (distributor or coil per spark plug

ignition systems).

Some engines seem to be equipped

with coil per plug systems but they

are actually DIS systems (eg.:

Peugeot 206, 306, etc.).

On engines equipped with Twin

Spark DIS systems (eg.: Alfa Romeo),

select 1spark per rev.

Wrong settings cause wrong

readings of RPM, Advance and

Dwell.

Loading...

Loading...