EA180 Series Servo Drive Users Manual

41

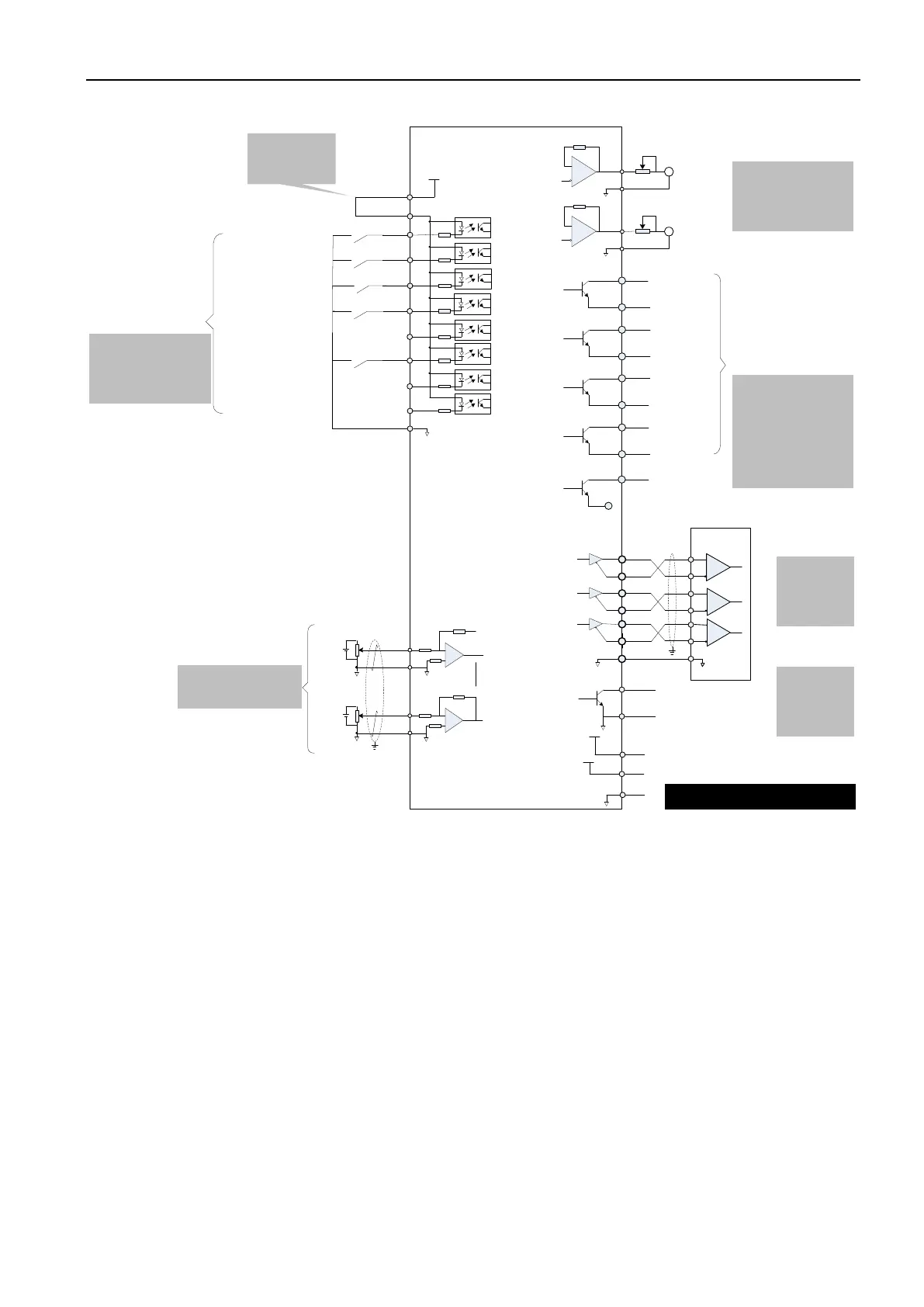

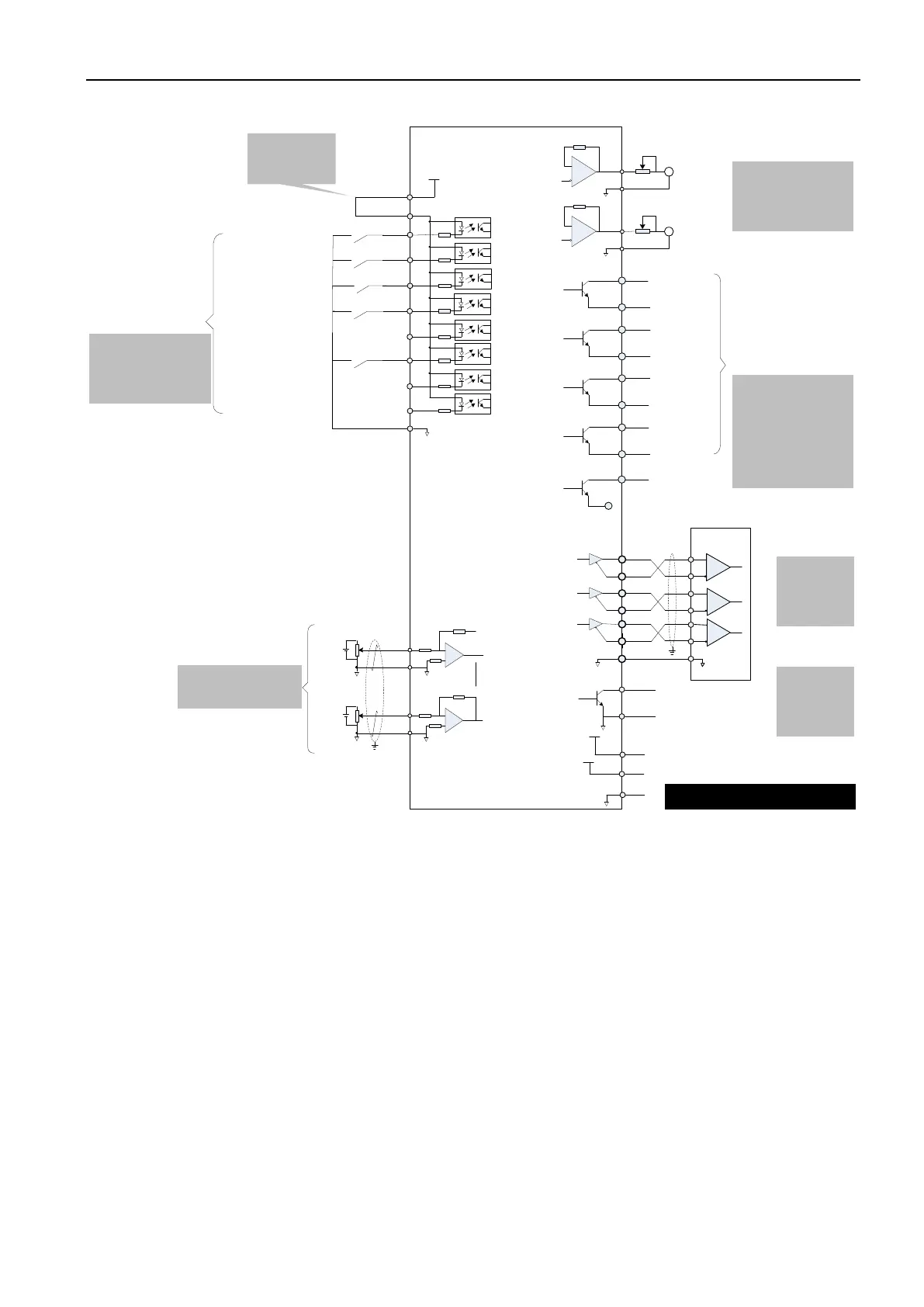

3.8.3 Torque control mode

8

23

37

38

9

24

39

10

DO1

DO1-

DO2

DO2-

DO3

DO3-

DO4

DO4-

State output

Encoder frequency

division pulse

output-differential

PE

PA+

PA-

PB+

PB-

PZ+

PZ-

28

13

12

27

26

GND

14

11

35

14

Upper

device

GND

Encoder phase Z

open collector

output

GND

OCZ

GND

AO1

Analog 1

output

Analog 2

output

15

29

30

29

GND

GND

AI2

AI1

EA180

servo drive

1. See P6 group function code

description for DO terminal

functions;

2. Refer to Section 3.4.6 for DO

terminal wiring method;

3. User-provided: DC5V ~ 24V

Max allowable voltage: DC30V

Max allowable current:

DC50mA

Servo ready

Brake output

Torque

comparison

Fault output

Refer to Section

3.4.9 for

frequency

division output

circuit

Refer to Section

3.4.9 for Z signal

output circuit

Refer to Section 3.4.7 for

analog input circuit

Refer to Section 3.6 for AO

output wiring

PE

+24V

+24V power

supply

25

COM+

21

DI1

5

DI2

20

4

DI3

19

3

18

2

DI4

DI5

DI6

DI7

17

DI8

ALM-RST

N-OT

TDIR-SEL

S-ON

P-OT

COM

State input

1. See P6 group function

code description for

functions of DI terminals

2. See Section 3.4.5 for DI

terminal wiring method

Standard connection

uses the internal

+24V power supply

by default

7

Servo enabled

Alarm reset clear

No positive drive

No negative drive

Torque command

direction selection

S-RDY

BK

Tcmp

ALM

A

GND

AO1

A

Speed command

Analog torque

Signal input: ± 10V

Input impedance: 9kΩ

Analog torque limiting

Signal input: ± 10V

Input impedance: 9kΩ

C N 1 terminal

41

COM

DO5

Internal shorting

+5V

+5V

GND

6

29

Internal +5V power supply, with max

allowable current of 50mA

+10V

+10V

44

Internal +10V power supply, with max

allowable current 20mA (Note)

(Note)

Note: DO5/+10V is not supported by

all models

Figure 3-26 Torque control mode standard wiring diagram

3.9 Notes for control circuit wiring

The control circuit cable and the power cable must be separated at a minimum distance of

30cm.

If the control circuit cable is short and needs to be extended, please ensure that the shield is

reliably connected to ensure reliable shielding and grounding.

The + 24V of servo drive is referenced by COM, and + 5V/+ 10V is referenced by GND. The

load should not exceed the maximum allowable current, otherwise the drive will not work

properly.

Try to use the shortest command input and encoder cables.

Please use cables above 1.5 mm

2

for grounding.

Single ground point is required.

Loading...

Loading...