4.

TO

RESET NEEDLE

BAR

BUSHING

Remove

face

plate,

as

instructed on

page

16.

Turn machine pulley

over

av/ay

from you until

needle

bar

has

reached

its highest position.

Drive

needle

bar

bushing

02,

Fig.

30,

page

13 up or

down

in casting

as

required

to

bring

its

lower

end

level

with

the

lower

timing

mark

M2, Fig.

30

on

needle

bar.

Replace face plate, as instructed on

page

16.

5.

TO

TIME

SEWING

HOOK

Remove presser foot, slide plate,

throat

plate,

bob

bin

case

and

feed

dog.

Select a

needle

in

good

condition

and

set

it in

needle

bar

as instructed on

page

6.

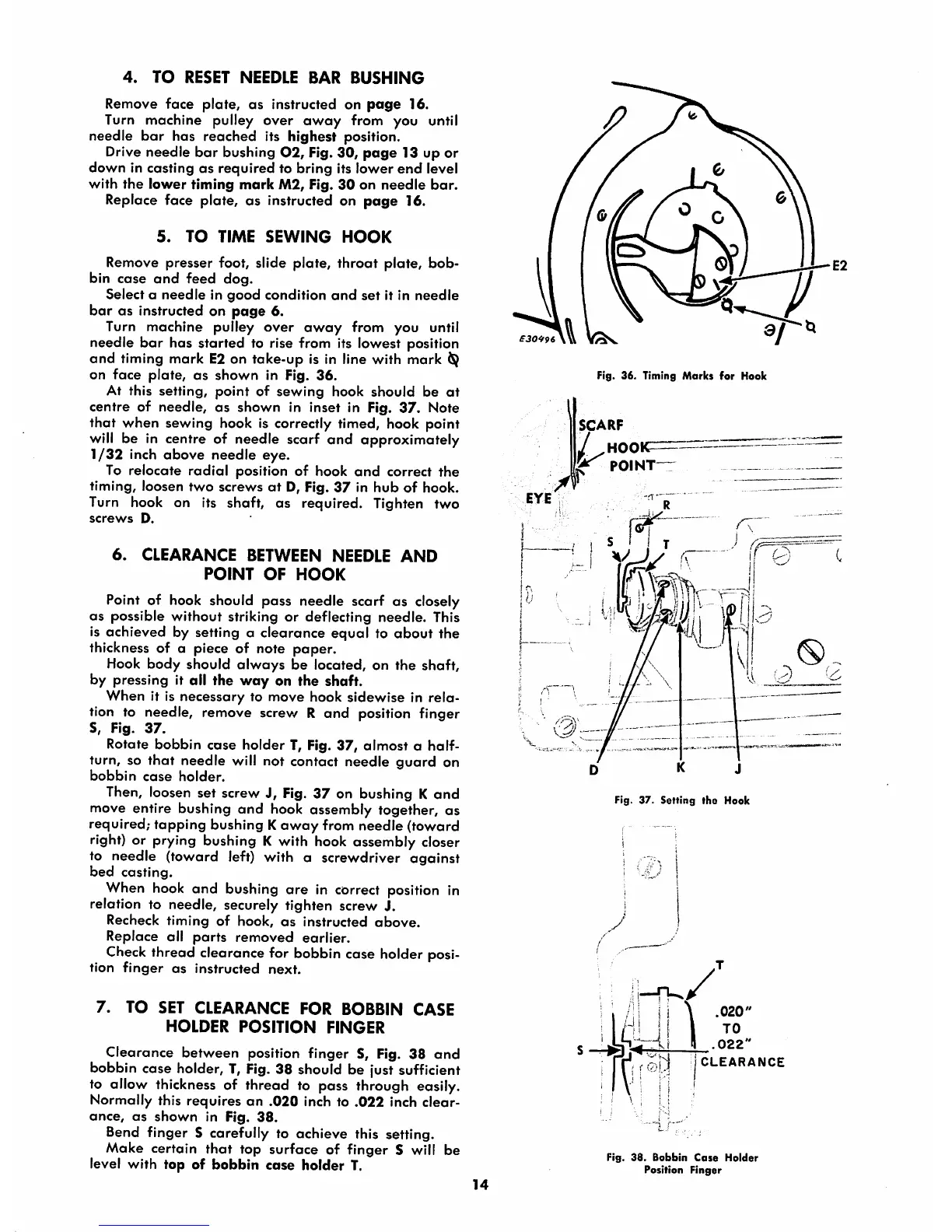

Turn

machine

pulley

over

away

from

you

until

needle

bar

has

started

to rise from its lowest position

and

timing mark E2 on take-up is in line with

mark

on

face

plate,

as

shown

in Fig.

36.

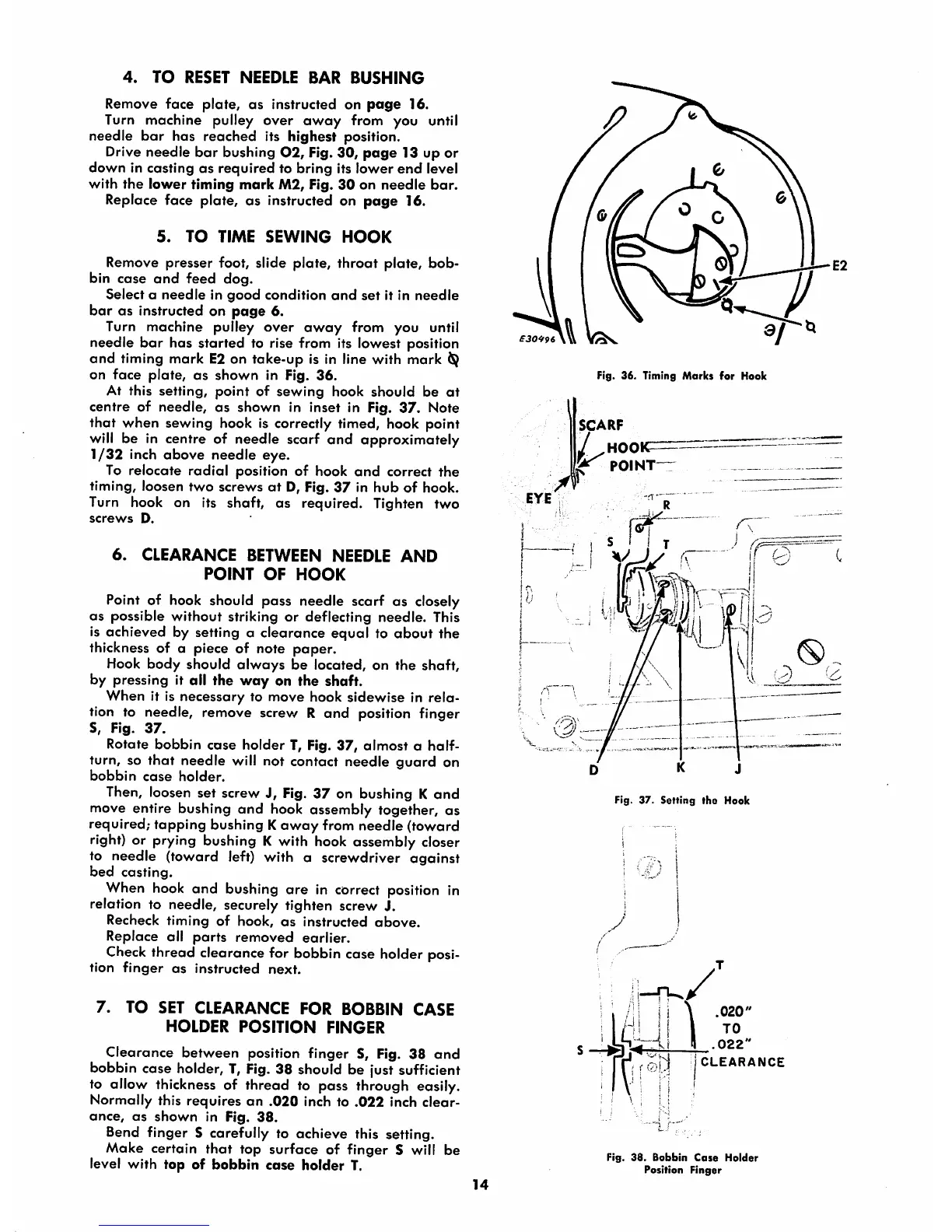

At this setting,

point

of

sewing

hook

should

be

at

centre of needle,

as

shown in inset in Fig.

37.

Note

that

when

sewing hook is correctly timed, hook point

will be in centre of needle scarf

and

approximately

1/32

inch

above

needle eye.

To relocate

radial

position of hook

and

correct

the

timing, loosen

two

screws

at

D, Fig.

37

in

hub

of

hook.

Turn hook on its shaft,

as

required. Tighten two

screws

D.

6.

CLEARANCE

BETWEEN

NEEDLE

AND

POINT

OF

HOOK

Point of hook should pass needle scarf as closely

OS

possible

without

striking

or

deflecting needle. This

is achieved by setting a clearance

equal

to

about

the

thickness of a piece of note

paper.

Hook

body

should

always

be located, on

the

shaft,

by pressing it all the

way

on the shaft.

When it is necessary to move hook sidewise in rela

tion to needle, remove screv/ R

and

position finger

S, Fig.

37.

Rotate

bobbin

case

holder

T, Fig.

37,

almost

a half-

turn, so

that

needle will not contact needle

guard

on

bobbin

case

holder.

Then, loosen set screw J, Fig. 37 on bushing K

and

move entire bushing

and

hook assembly together, as

required; tapping bushing K

away

from needle (toward

right) or prying bushing K with hook assembly closer

to needle (toward left) with a screwdriver

against

bed

casting.

When

hook

and bushing are in correct position in

relation to needle, securely tighten screw J.

Recheck timing of hook,

as

instructed

above.

Replace all

parts

removed

earlier.

Check

thread clearance for bobbin cose holder posi

tion

finger

as

instructed

next.

7.

TO SET CLEARANCE FOR BOBBIN CASE

HOLDER

POSITION

FINGER

Clearance between position finger S, Fig. 38

and

bobbin cose holder, T,

Fig.

38 should be just sufficient

to allow thickness of thread to pass through easily.

Normally

this

requires

an

.020

inch to

.022

inch

clear

ance,

as

shown

in Fig.

38.

Bend finger S carefully to achieve this setting.

Make certain

that

top surface of finger S will be

level with top of bobbin case holder T.

14

Fig.

36.

Timing

Marks

for

Hook

SCARF

HOOK

POINT

D K J

Fig.

37.

Setting

the

Hook

y

:

.022

j

CLEARANCE

Fig.

38.

Bobbin

Case

Holder

Position

Finger

Loading...

Loading...