THE

HOOK

DRIVING

SHAFT

REMOVAL

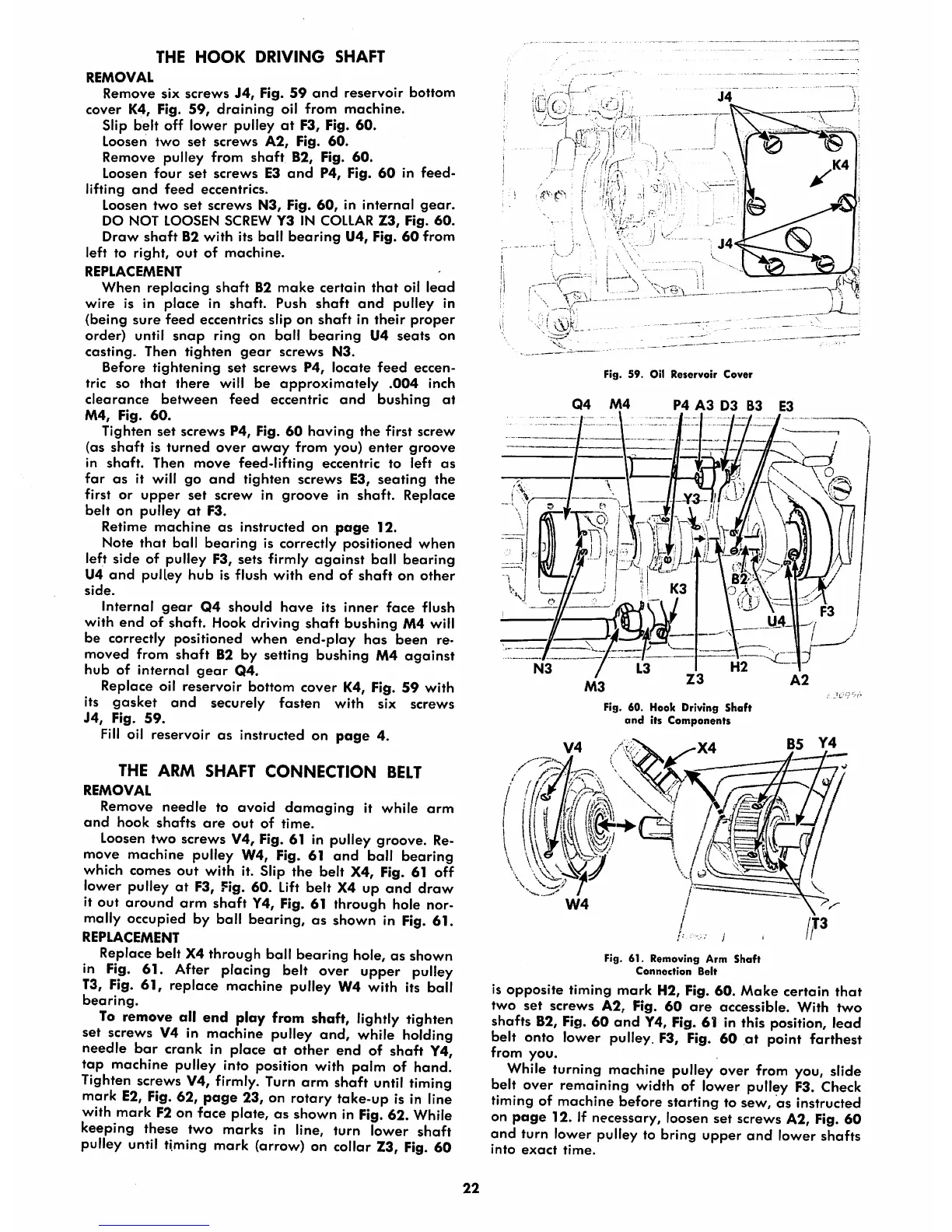

Remove six

screws

J4,

Fig.

59

and

reservoir

bottom

cover

K4, Fig.

59,

draining

oil

from

machine.

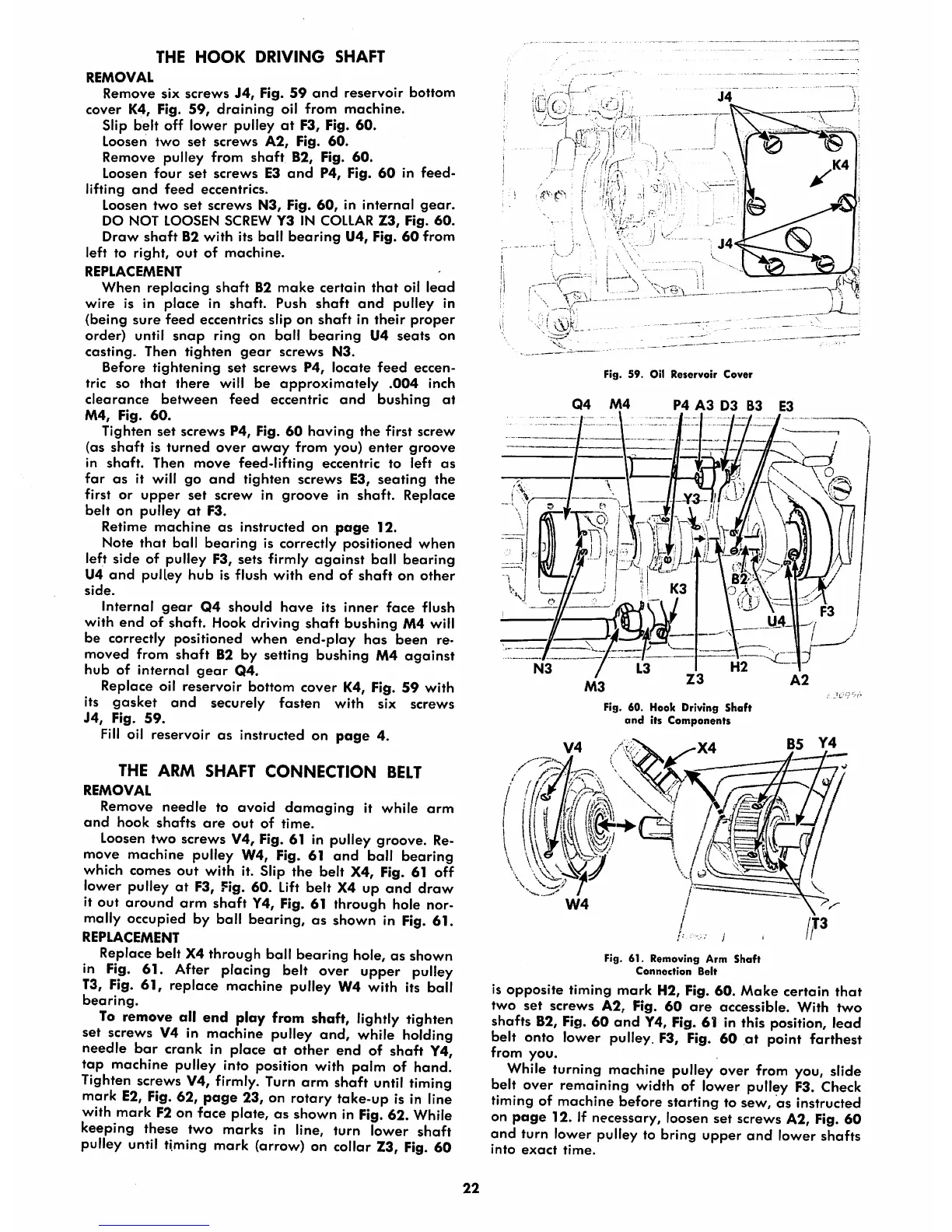

Slip

belt

off

lower

pulley

at

F3, Fig.

60.

Loosen

two

set

screws

A2,

Fig.

60.

Remove pulley from

shaft

B2, Fig.

60.

Loosen

four

set

screws

E3

and

P4, Fig.

60

in

feed-

lifting

and

feed

eccentrics.

Loosen

two

set

screws

N3, Fig.

60,

in

internal

gear.

DO NOT LOOSEN SCREW Y3 IN COLLAR

Z3,

Fig.

60.

Draw

shaft

B2

with

its

ball

bearing

U4, Fig.

60

from

left to

right,

out

of

machine.

REPLACEMENT

When

replacing

shaft

B2

make

certain

that

oil

lead

wire

is in

place

in

shaft.

Push

shaft

and

pulley

in

(being

sure

feed

eccentrics slip on

shaft

in

their

proper

order) until

snap

ring on ball

bearing

U4

seats

on

casting.

Then

tighten

gear

screws

N3.

Before

tightening

set

screws

P4,

locate

feed

eccen

tric so

that

there

will be

approximately

.004

inch

clearance

between

feed

eccentric

and

bushing

at

M4,

Fig.

60.

Tighten

set

screws

P4, Fig.

60

having

the

first

screw

(as

shaft

is

turned

over

away

from you)

enter

groove

in

shaft.

Then

move

feed-lifting

eccentric

to

left

as

far

as

it will

go

and

tighten

screws

E3,

seating

the

first or

upper

set

screw

in

groove

in

shaft.

Replace

belt

on pulley

at

F3.

Retime

machine

as

instructed on

page

12.

Note

that

ball

bearing

is correctly positioned

when

left side of pulley F3, sets firmly

against

ball

bearing

U4

and

pulley

hub

is flush

with

end

of

shaft

on

other

side.

Internal

gear

Q4

should

hove

its

inner

face

flush

with

end

of

shaft.

Hook driving

shaft

bushing

M4 will

be correctly positioned when end-ploy has been re

moved from

shaft

B2 by setting bushing M4

against

hub

of

internal

gear

Q4.

Replace oil reservoir bottom cover K4, Fig. 59 with

its

gasket

and

securely fasten with six screws

J4,

Fig.

59.

Fill

oil reservoir as instructed on

page

4.

THE

ARM

SHAFT

CONNECTION

BELT

REMOVAL

Remove

needle

to

ovoid

damaging

it while

arm

and

hook

shafts

are

out

of

time.

Loosen

two screws V4, Fig. 61 in pulley groove. Re

move machine pulley W4, Fig. 61 and ball bearing

which comes out with it. Slip the belt X4, Fig. 61 off

lower pulley at

F3,

Fig. 60.

Lift

belt X4 up and draw

it out

around

arm

shaft

Y4, Fig. 61 through hole nor

mally occupied by boll bearing, as shown in

Fig.

61.

REPLACEMENT

Replace belt X4 through boll bearing hole, as shown

in

Fig.

61. After placing belt over upper pulley

13, Fig.

61,

replace machine pulley W4 with its ball

bearing.

To

remove all end ploy from shaft, lightly tighten

set screws V4 in machine pulley

and,

while holding

needle

bar

crank In place at other end of shaft Y4,

tap machine pulley into position with palm of hand.

Tighten

screws

V4,

firmly.

Turn

arm shaft

until

timing

mark

E2,

Fig.

62, page 23, on rotary take-up is in line

with mark

F2

on face plate, as shown in

Fig.

62. While

keeping these two marks in line, turn lower shaft

pulley

until

timing

mark

(arrow)

on collar

Z3,

Fig.

60

22

Fig.

59.

Oil

Reservoir

Cover

Q4

M4

P4

A3

D3 B3 E3

Fig. 60. Hook Driving

Shaft

and

its Components

B5

Y4

Fig. 61.

Removing

Arm

Shaft

Connection

Belt

is

opposite

timing

mark

H2, Fig.

60.

Make

certain

that

two

set

screws

A2,

Fig.

60

ore

accessible.

With

two

shafts B2,

Fig.

60 and

Y4,

Fig. 61 in this position, lead

belt onto lower pulley. F3, Fig. 60 at point farthest

from you.

While turning machine pulley over from you, slide

belt over remaining width of lower pulley

F3.

Check

timing of machine

before

starting

to sew,

as

instructed

on

page

12. If necessary, loosen set screws A2, Fig. 60

and turn lower pulley to bring upper

and

lower shafts

into

exact

time.

Loading...

Loading...