Fig. 62. Timing

Marks

at

Face

Plate

iC3«l

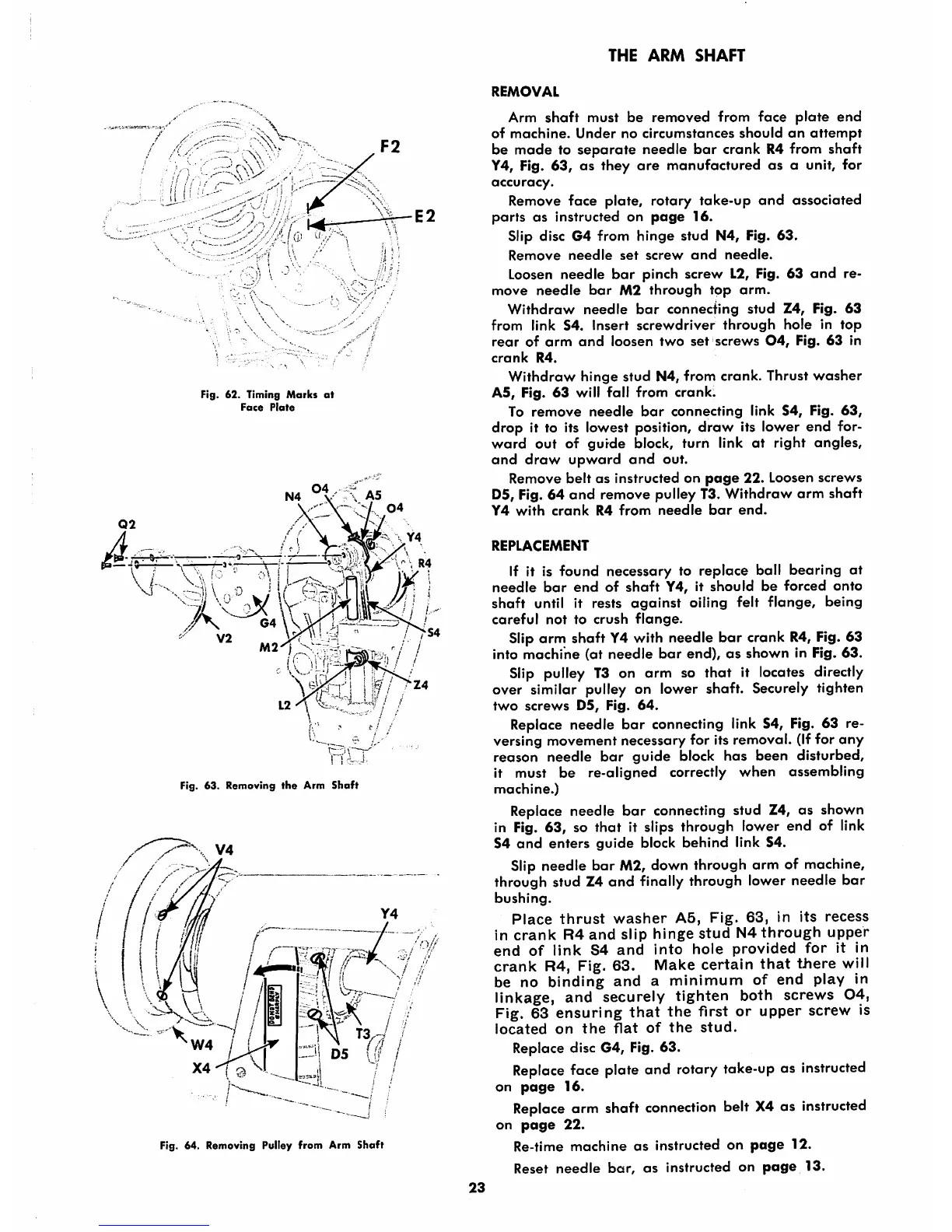

Fig. 63. Removing

the

Arm

Shaft

W4

/

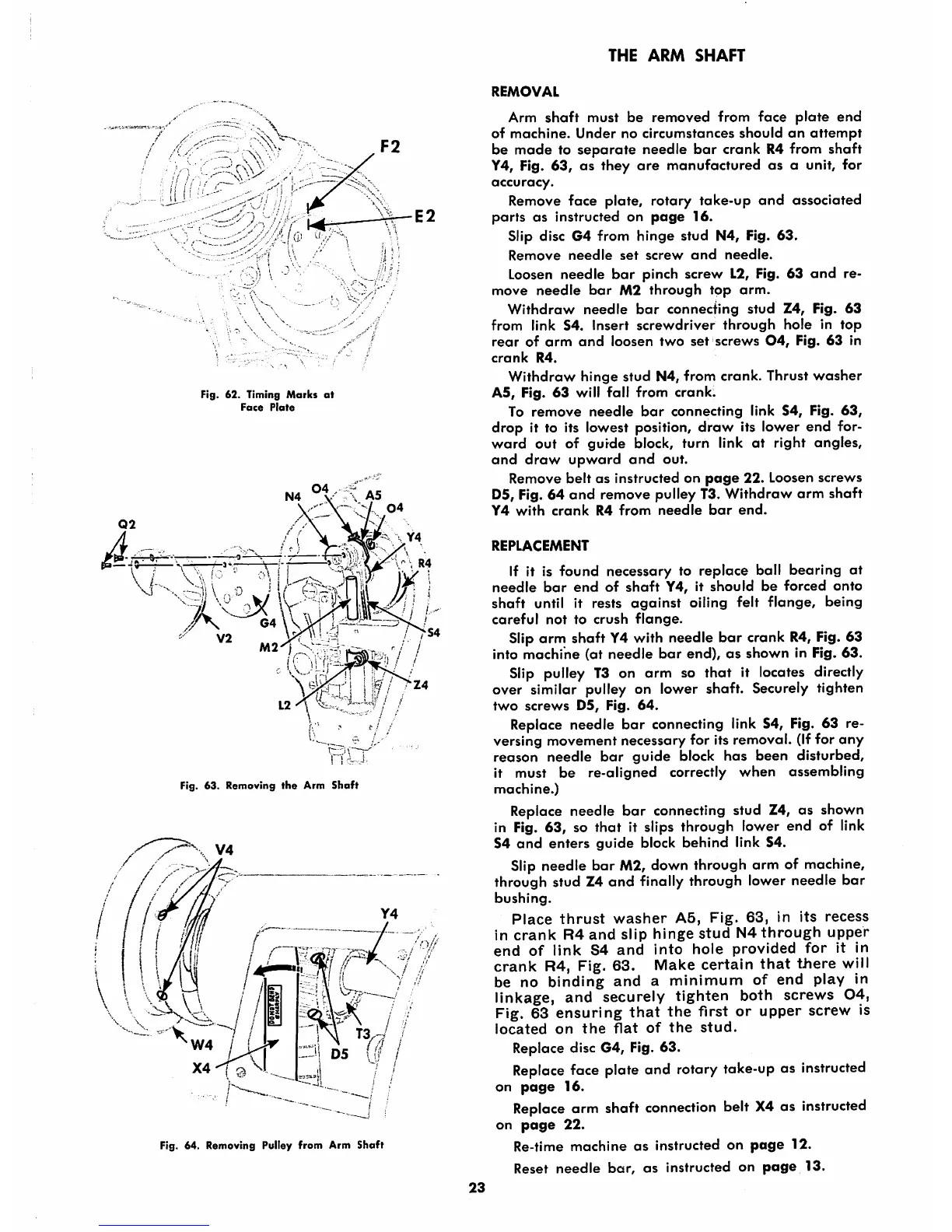

Fig. 64. Removing Pulley from Arm Shaft

THE

ARM

SHAFT

REMOVAL

Arm

shaft

must

be

removed

from

face

plate

end

of

machine.

Under

no

circumstances

should

an

attempt

be

made

to

separate

needle

bar

crank R4 from

shaft

Y4, Fig.

63,

as they

are

manufactured

as

a unit, for

accuracy.

Remove face plate, rotary take-up

and

associated

parts

as

instructed on

page

16.

Slip disc G4 from

hinge

stud N4, Fig. 63.

Remove

needle

set

screw

and

needle.

Loosen needle

bar

pinch screw 12, Fig. 63

and

re

move

needle

bar

M2

through

top

arm.

Withdraw

needle

bar

connecting

stud

Z4, Fig.

63

from link 54. Insert

screwdriver

through

hole

in

top

rear

of

arm

and

loosen

two

set

screws

04,

Fig,

63

in

crank

R4.

Withdraw

hinge

stud

N4,

from

crank.

Thrust

washer

AS, Fig. 63 will fall from

crank.

To

remove

needle

bar

connecting

link

54,

Fig.

63,

drop it to its lowest position,

draw

its lower end for

ward

out

of

gurde

Islock,

turn

link

at

right

angles,

and

draw

upward

and

out.

Remove

belt

as instructed on

page

22. Loosen screws

D5, Fig. 64

and

remove pulley T3. Withdraw

arm

shaft

Y4

with

crank

R4

from

needle

bar

end.

REPLACEMENT

If it is found necessary to replace ball bearing at

needle

bar

end

of

shaft

Y4, it

should

be

forced

onto

shaft

until it rests

against

oiling felt

flange,

being

careful

not

to

crush

flange.

Slip arm shaft Y4 with needle

bar

crank R4, Fig. 63

into

machine

(at

needle

bar

end),

as

shown

in Fig.

63.

Slip pulley

T3

on arm so that it locates directly

over similar pulley on lower shaft. Securely tighten

two

screws

D5,

Fig.

64.

Replace needle

bar

connecting link 54, Fig. 63 re

versing movement necessary for its removal. (Iffor any

reason needle

bar

guide

block

has

been disturbed,

it must be re-aligned correctly

when

assembling

machine.)

Replace needle

bar

connecting stud Z4, as shown

in Fig. 63, so that it slips through lower end of link

54

and

enters

guide

block

behind

link 54.

Slip needle bar M2, down through arm of machine,

through stud Z4

and

finally through lower needle

bar

bushing.

Place

thrust

washer

A5,

Fig.

63,

in

its

recess

in

crank

R4

and

slip

hinge

stud

N4

through

upper

end

of

link

S4

and

into

hole

provided

for

it in

crank

R4, Fig. 63. Make certain

that

there

will

be no

binding

and

a

minimum

of

end

play in

linkage, and securely tighten both screws

04,

Fig. 63 ensuring

that

the first or upper screw is

located

on

the

flat

of

the

stud.

Replace disc G4, Fig. 63.

Replace

face plate and rotary take-up as

instructed

on

page

16.

Replace

arm shaft

connection

belt

X4

as

instructed

on

page

22.

Re-time

machine

as

instructed on

page

12.

Reset

needle

bar,

as

instructed on

page

13.

23

Loading...

Loading...