}

iL

B4

r 1 V

>'

• /

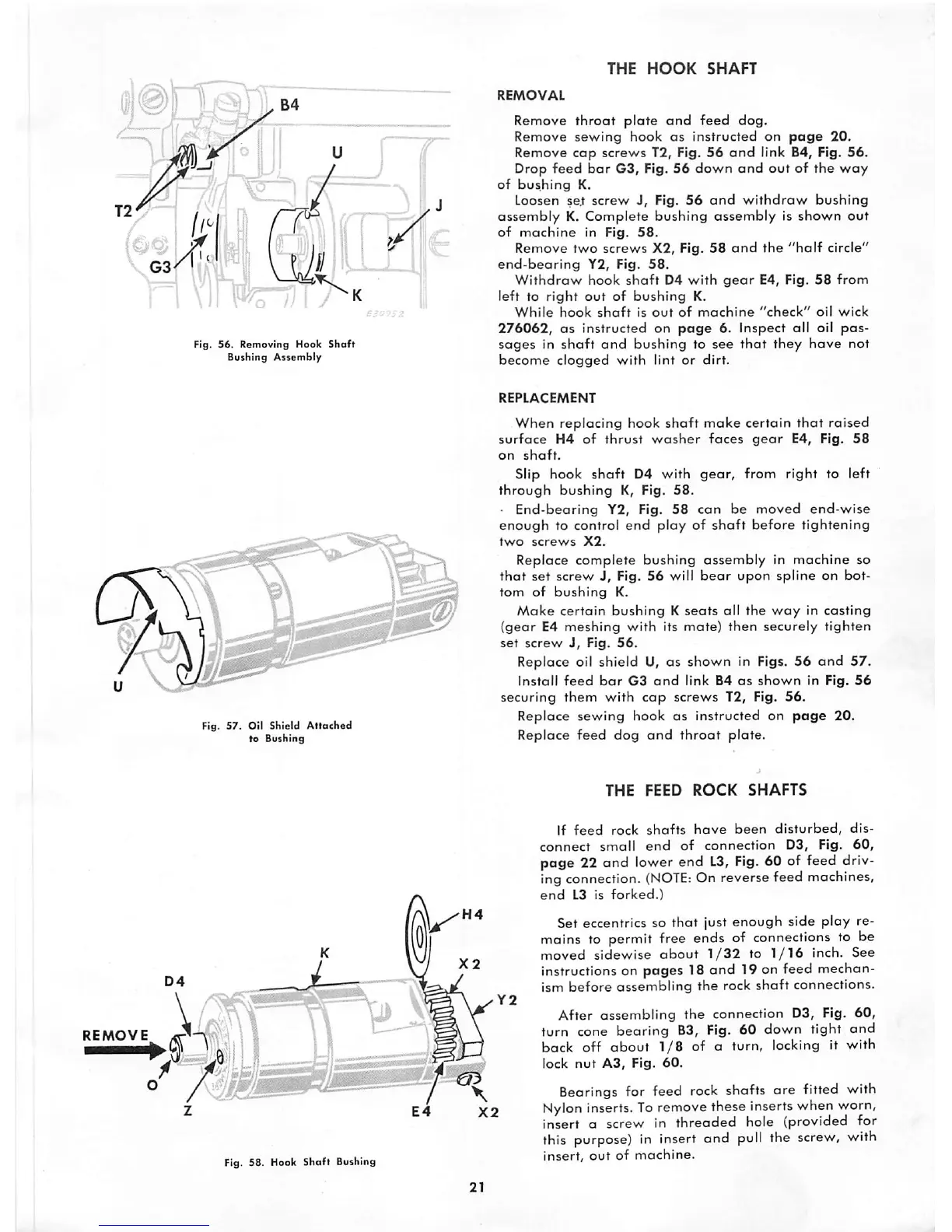

Fig.

56.

Removing

Hook

Shaft

Bushing

AssembI/

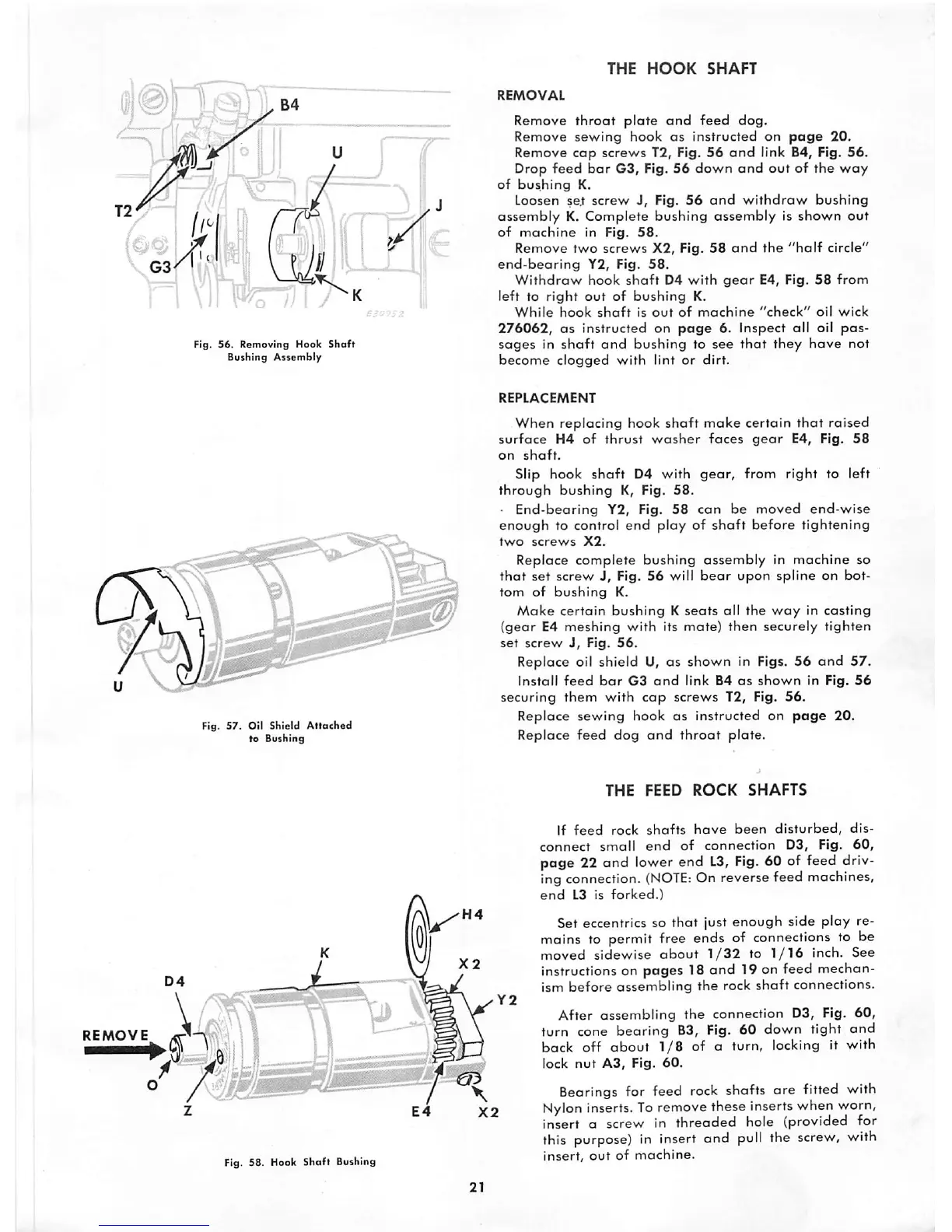

Fig. 57. Oil Shield

Attached

to

Bushing

Fig. 58. Hook Shaft Bushing

THE

HOOK

SHAFT

REMOVAL

Remove

throat

plate

and

feed

dog.

Remove

sewing

hook as instructed on

page

20.

Remove

cap

screws

T2, Fig.

56

and

link B4, Fig.

56.

Drop

feed

bar

G3, Fig. 56

down

and

out

of

the

way

of

bushing

K.

Loosen se.t

screw

J, Fig.

56

and

withdraw

bushing

assembly

K. Complete bushing assembly is shown

out

of

machine

in Fig.

58.

Remove

two

screws

X2, Fig.

58

and

the

"half

circle"

end-bearing

Y2, Fig.

58.

Withdraw

hook

shaft

D4

with

gear

E4, Fig.

58

from

left

to

right

out

of

bushing

K.

While

hook

shaft

is

out

of

machine

"check"

oil

wick

276062,

as instructed on

page

6. Inspect all oil

pas

sages

in

shaft

and

bushing

to

see

that

they

have

not

become

clogged

with

lint

or

dirt.

REPLACEMENT

When replacing hook

shaft

make

certain

that

raised

surface

H4

of

thrust

washer

faces

gear

E4, Fig.

58

on

shaft.

Slip hook

shaft

D4 with

gear,

from right to left

through

bushing

K, Fig.

58.

End-bearing

Y2, Fig.

58

can

be

moved

end-wise

enough

to control

end

play

of

shaft

before

tightening

two

screws

X2.

Replace

complete

bushing

assembly

in

machine

so

that

set

screw

J,

Fig.

56

will

bear

upon

spline

on

bot

tom

of

bushing

K.

Make

certain

bushing

K

seats

all

the

way

in

casting

(gear

E4

meshing

with

its

mate)

then

securely

tighten

set

screw

J,

Fig.

56.

Replace oil

shield

U, as

shown

in Figs.

56

and

57.

Install

feed

bar

G3

and

link B4

as

shown

in Fig.

56

securing

them

with

cap

screws

T2, Fig.

56.

Replace

sewing

hook as instructed on

page

20.

Replace

feed

dog

and

throat

plate.

X2

THE

FEED

ROCK

SHAFTS

If

feed

rock

shafts

have

been

disturbed,

dis

connect

small

end

of

connection

D3, Fig.

60,

page 22 and lower end

L3,

Fig.

60 of feed driv

ing connection.

(NOTE:

On reverse feed machines,

end

L3 is

forked.)

Set eccentrics so that just enough side play re

mains to permit free ends of connections to be

moved

sidewise

about

1/32

to

1/16

inch.

See

instructions on pages 18 and 19 on feed mechan

ism

before

assembling

the

rock

shaft

connections.

After

assembling

the

connection D3, Fig.

60,

turn cone bearing B3, Fig. 60 down tight

and

back off

about

1/8

of a turn, locking it with

lock

nut

A3,

Fig.

60.

Bearings for feed rock shafts

are

fitted with

Nylon

inserts.

To

remove

these inserts when worn,

insert a screw in

threaded

hole (provided for

this

purpose)

in insert and

pull

the

screw,

with

insert,

out

of

machine.

Loading...

Loading...