SILVERCUT

25

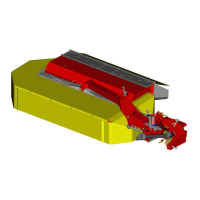

– Lower all four support legs (1) and secure them with

safety device (2) in middle hole of the support leg

(1).

– Disconnect the P.T.O. shaft (3) and put it on the

holder (4).

– Lower the machine and make sure that it is placed

steady.

– Disconnect the hydraulic tubes (5), secure them

with quick clamps and put them into the deposit

place on the hitch (6).

– Disconnect the electric plug and put it into the

deposit place on the hitch (6).

– Pull the strings (8) from the tractor and mount

them on the connector.

– Loosen and disconnect the upper lever.

– Disconnect the lower levers and drive away.

7. Maintenance and periodical overhauls

7.1 Special safety instructions

– Repair works, maintenance, periodical

overhauls, cleaning and elimination of

funtctional disturbances must be

performed with the switched off drive

and stand still engine! Remove the

ignition key!

– When injured with splashed oil find

medical help immidiately.

– Consider other safety instructions to

prevent damages and accidents.

7.2 General

To insure faultless working of the

machine and to reduce the wear out

always consider the maintenance

instructions and periodical overhauls.

This includes cleaning, greasing and

lubricating of built in parts and

components.

Screws and nuts tightening moment MA

(if not stated otherwise)

A = size of coil

A

Ø

8.8 10.9 12.9

M

A

(Nm)

M 4 3,0 4,4 5,1

M 5 5,9 8,7 10

M 6 10 15 18

M 8 25 36 43

M 10

49 72 84

M 12 85 125 145

M 14 135 200 235

M 14x1,5 145 215 255

M 16 210 310 365

M 16x1,5 225 330 390

M 20 425 610 710

M 24 730 1050 1220

M 24x1,5

M 24x2 800 1150 1350

M 27 1100 1550 1800

M 27x1,5 850

M 27x2 1150 1650 1950

M 30 1450 2100 2450

–

After the first start and few hours of

working check the tightness of nuts

and screws, tighten them if needed.

–

Check up regulary (approx. every 50

hours)!

Loading...

Loading...