Operation instructions

SIPOS 5 PROFITRON, HiMod

Page 10 Y070.020/GB

3 Assembly and connection

3

Assembly and connection

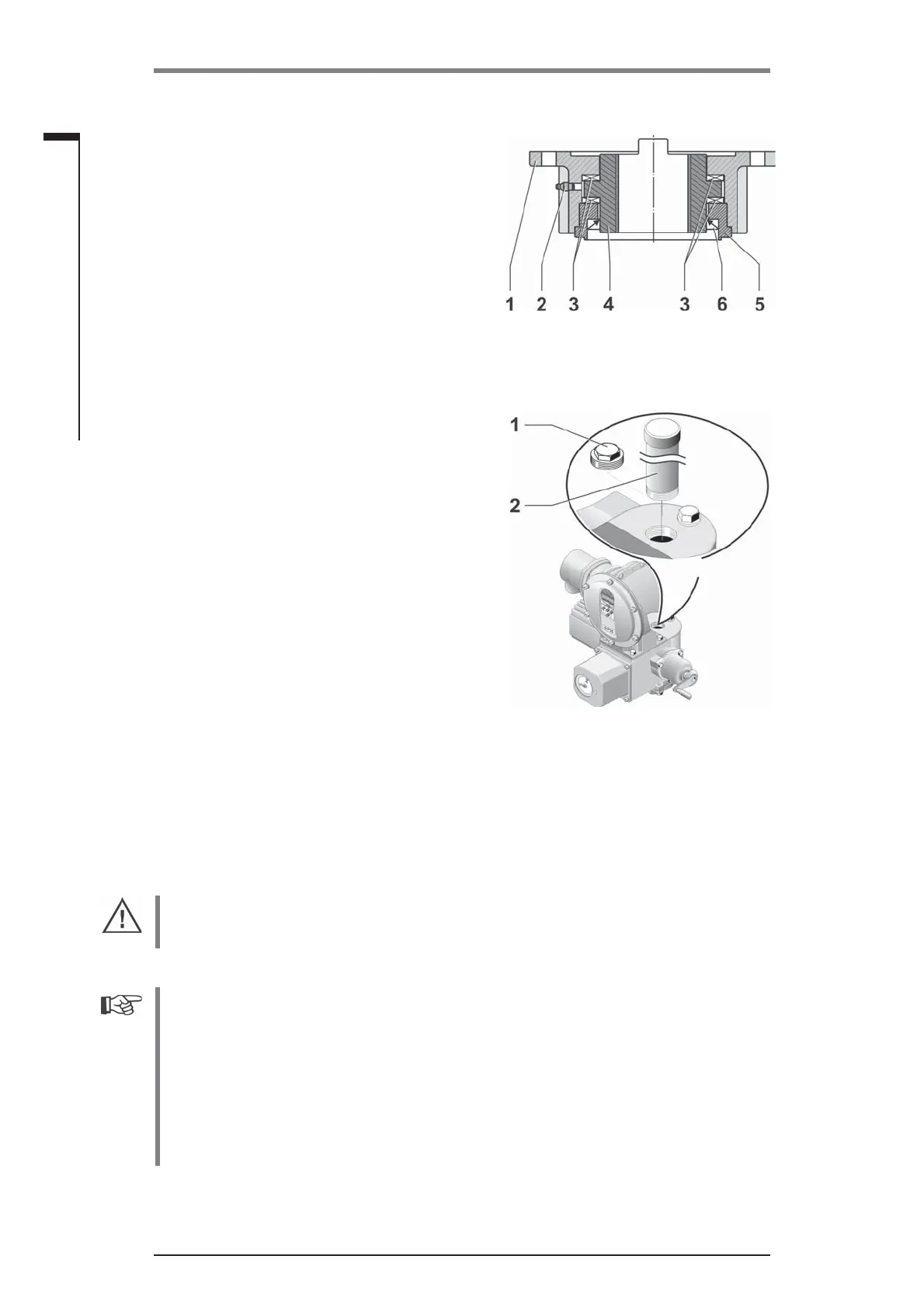

5. Lubricate axial needle-roller bearings and axial

bearing washers (3) with ball bearing grease and

fi t them on the new or machined stem nut (4).

6. Insert stem nut (4) with axial needle-roller as-

sembly into output fl ange (claws have to engage

properly into the groove of the output shaft of the

actuator).

7. Screw in the centering ring (5) and tighten it as

far as the stop.

Make sure the radial seal is inserted correctly (6).

8. Using a grease gun, press ball bearing grease

into the grease nipple (2) until lubricant is dischar-

ged between the centering ring (5) and the stem

nut (4).

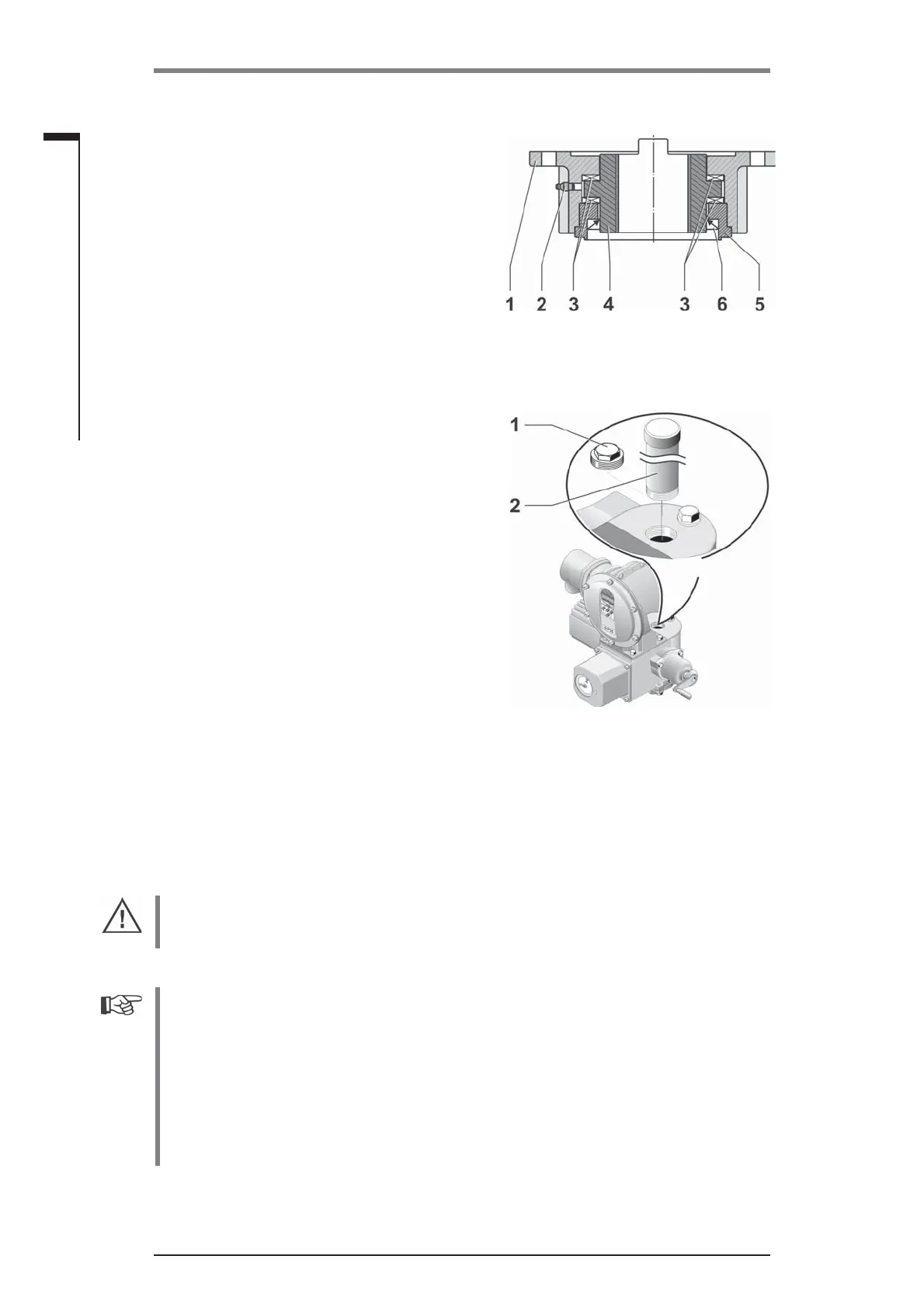

3.1.3 Mount spindle protection tube

1. Remove fastener (fi g., item 1).

2. Check that the extended stem does not exceed

the length of the protective tube.

3. Apply sealing compound to the thread and the

sealing faces (e.g. 732 RTV from Dow Corning,

Munich, Germany).

4. Screw in the spindle protection tube (2).

Fig.: Output shaft type A installed

Fig.: Mounting the spindle protection

tube

3.2 Electrical connection

The components are designed as to ensure that once connected correctly, uninsulated, live parts

cannot be touched directly; i.e. protection against electric shock is provided in accordance with

IP2X or IPXXB .

Dangerous voltages are also present when the motor is at a standstill. Before opening the

terminal cover or the connection hood, disconnect the supply voltage from the actuator. Allow 5

minutes for the capacitors to discharge and do not touch any contacts.

■

The supply voltage must always lie within the voltage range specifi ed on the rating plate.

■

Mains cable: Use metal cable glands for mains connection.

■

Signal cable: Use metal cable glands with cable shielding for the connection of the control

cable to avoid the occurrence of electronic faults. The signal cable must be shielded and the

shield must be fi xed or earthed on both sides. Ensure careful connection of the screen within

the cable gland!

■

It must be ensured that the cable glands and seals (O-rings) are fi tted carefully and correctly

in order to guarantee the enclosure protection. For details of the permissible conductor cross-

sections, see wiring diagram.

■

Cable glands and cables are not included in the scope of delivery.

Loading...

Loading...