DANGER

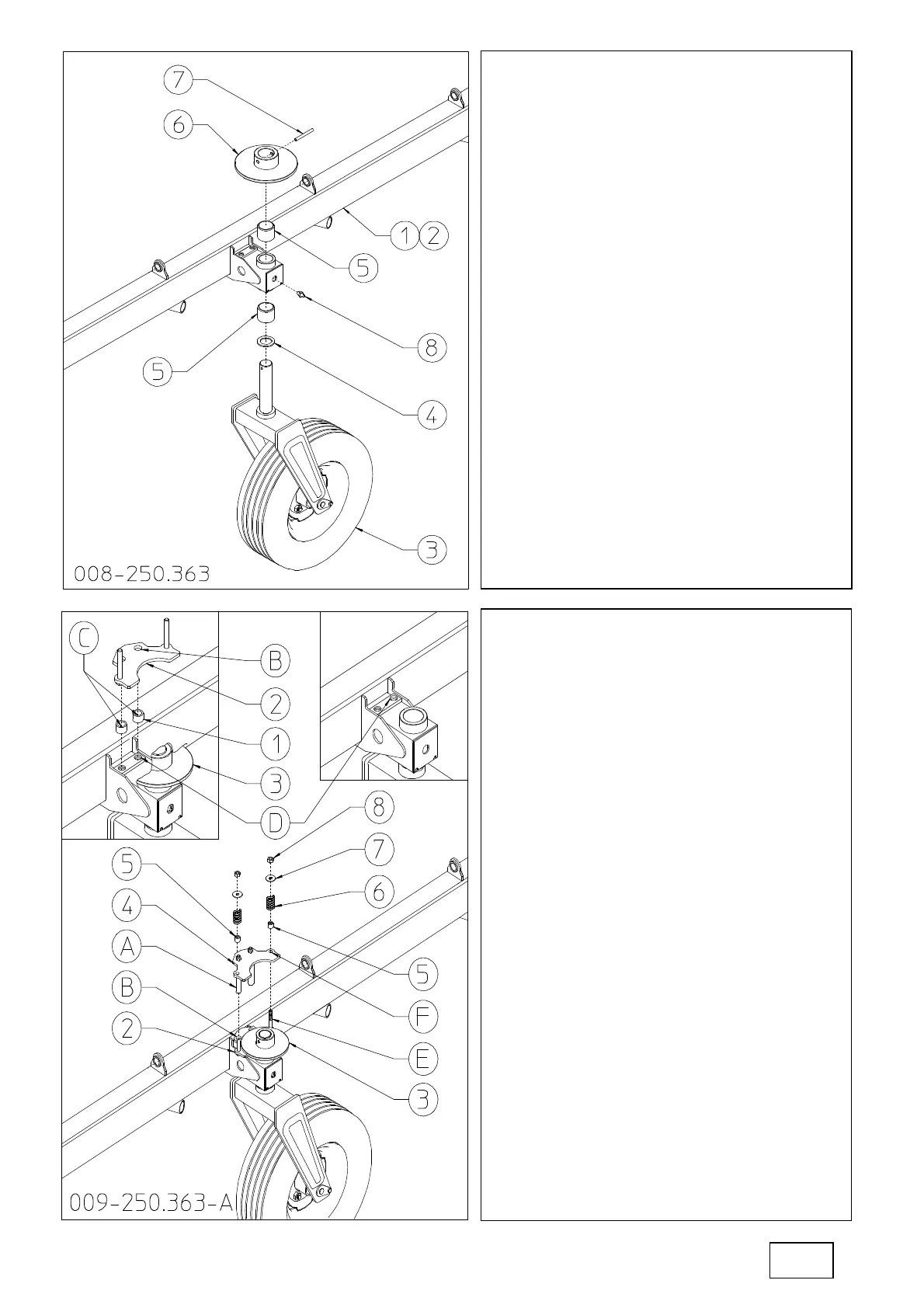

Insert the nylon bushings 5 into the

openings in sections 1-2 (RH-LH).

Place spacer 4 on the pins of the

wheel units 3. Insert the wheel units 3

into the openings in sections 1-2.

Attach the flange 6 onto the pins of the

wheel units 3 using the spring pins 7.

Attach the grease nipples 8 to the

openings in sections 1-2.

Before continuing make sure that the

wheel units 3 can turn freely.

In this step, you will use:

Item 4: 2 spacers ø50-76x5 (1.97”x3”)

Item 5: 4 nylon bushings ø50-60x50

(ø1.97”-2.36x1.97”)

Item 7: 2 spring pins ø10x80

(0.4”x3.15”)

Item 8: 2 grease nipples M8 (0.31”)

DANGER

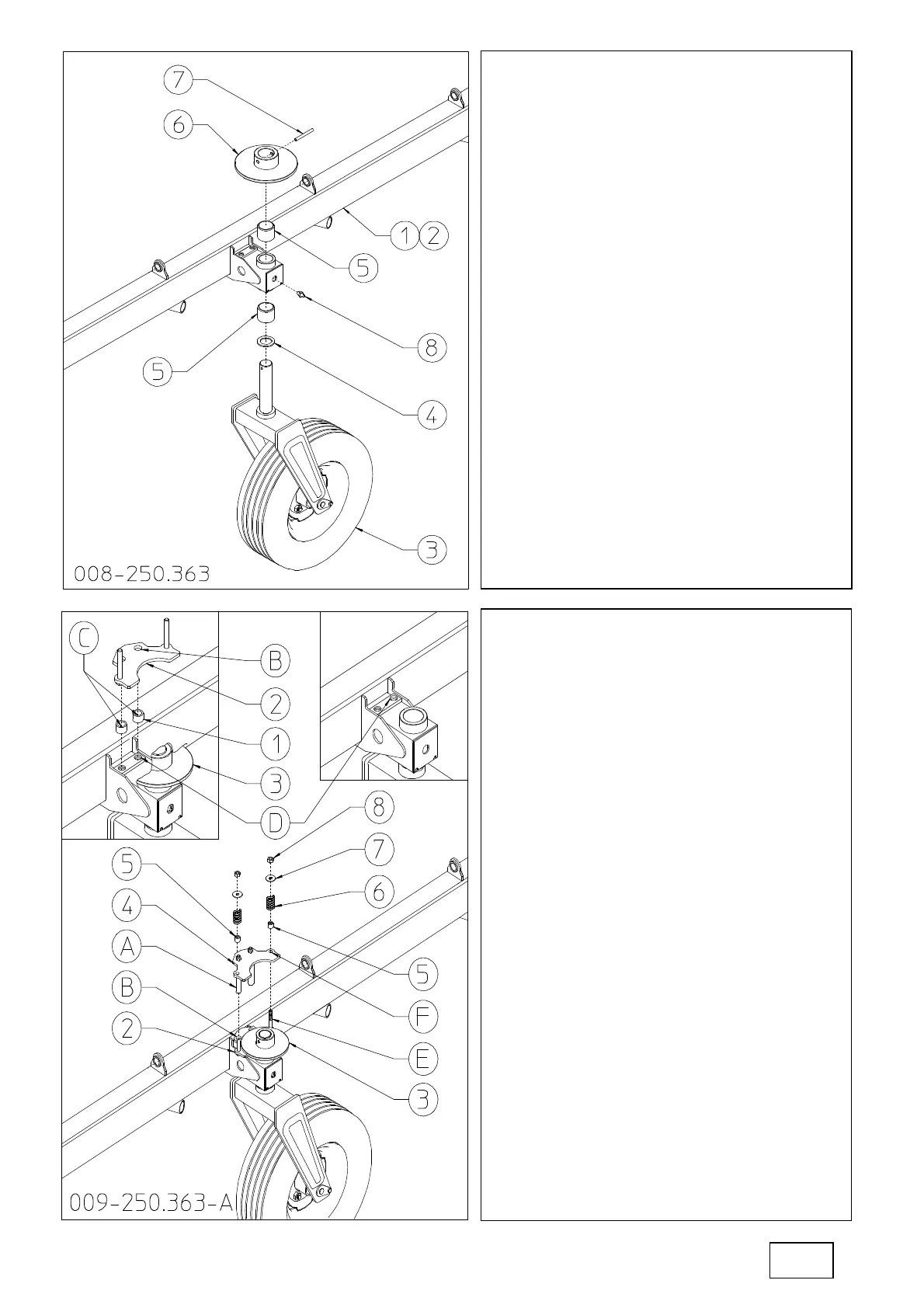

Attach the shims 1 and the plate with bolt 2

underneath flange 3. Attach the counterplate

4 over flange 3, inserting the counterplate

pins A (counterplate 4) into the holes B in

the plate with bolt 2, into the holes C in the

shims 1 and into holes D in the sections. The

plate screws E must go into the holes F of

the counter plate 4.

Place the bushing 5, spring 6 and washer 7

on the screw E and lock with the nut 8.

Note: the more spring 6 is compressed by

tightening nut 8, the more the turning of the

wheel is braked, therefore check that it is

adjusted properly when the machine is to be

operated (see machine use).

In this step, you will use:

Item 1: 4 shims ø21-30x10 (0.82”-

1.18”x0.39”)

Item 5: 4 bushings ø13-18x20 (0.5”-

0.71”x0.79”)

Item 6: 4 springs ø5-30x45 (0.20”-

1.18”x1.77”)

Item 7: 4 washers ø12-36x4 (ø0.47”-

1.42x0.16”)

Item 8: 4 nuts M12 (0.47”)

53

Loading...

Loading...