EN

5. Installation

5

- 17 -

951-150-032-EN

Version 09

• Detach and unscrew the defective piston

detector (3) from the metering device (4)

• Then check whether an adapter (7) is

already installed

Procedure for metering devices

without an adapter installed (7):

• If present, remove the old packing ring

(5) from the metering device (4)

(VP; VPB; VPK; PSG1; PSG2;

SSV/SSVL/SSVD/SSVDL)

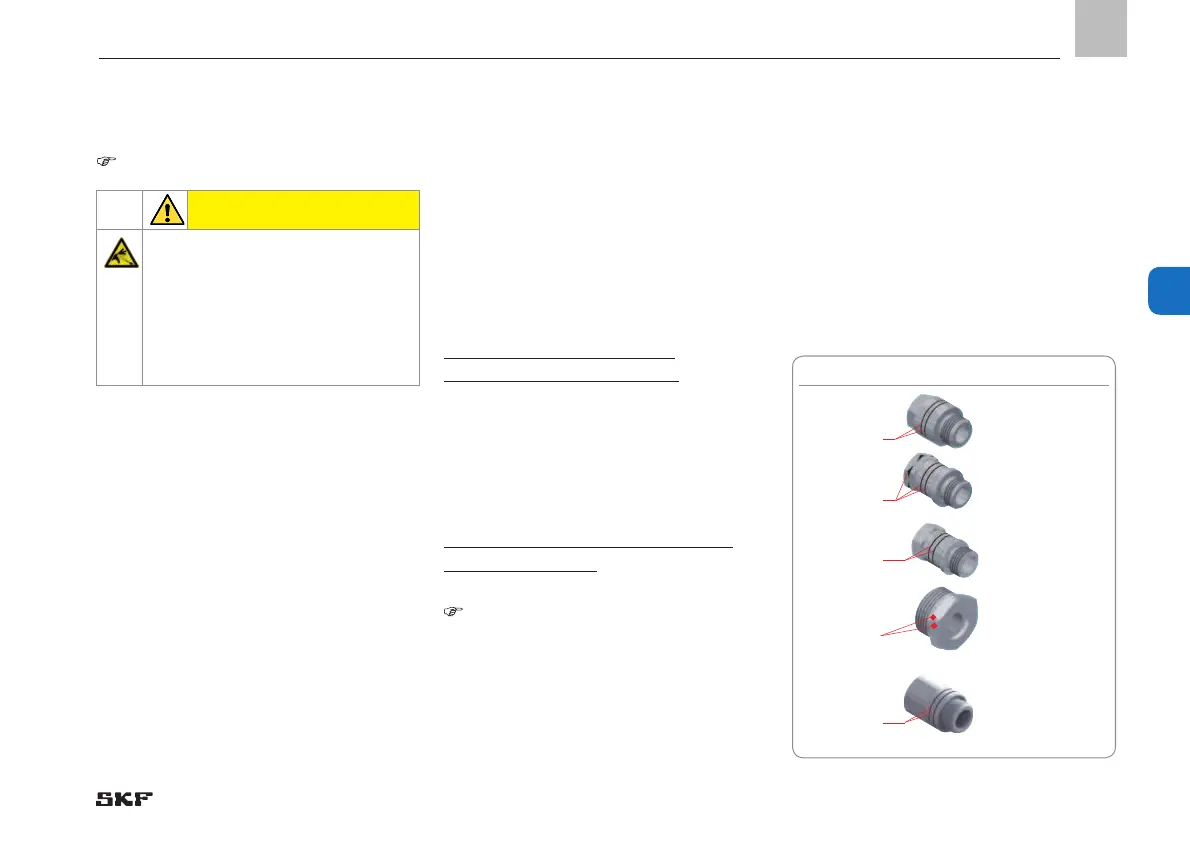

Procedure for metering devices with an

adapter installed (7):

The adapters (7) have different wall

thicknesses to match the piston detectors/

metering devices. Therefore check the iden-

tification of the adapter in accordance with

Figure 3 before installing the piston detector.

• Depressurize the lubrication system and

metering device

• If possible, place a drip pan for the dis-

charging lubricant below the correspond-

ing metering device

• Place individual parts of the new piston

detector replacement kit (1) on a clean

storage surface

• Disconnect the electrical connection

cable (2) from the old/defective piston

detector

CAUTION

Pressure hazard

Before beginning conversion work,

depressurize the system in which

the metering device with the piston

detector to be replaced is installed.

See Figures 1 to 3

5.1 Removal of the old piston detector

• If the adapter identification (rings) of the

adapter that is already installed does not

match the identification in Figure 3, dis-

connect the old adapter (7) and remove it

from the metering device (4)

Adapter identification, Fig. 3

2 rings

VP and PSG2

3 rings

VPK and PSG1

2 rings

VPB

SSV, SSVL,SSVD,

SSVDL,SSVC,SLC

,VSG,VSL

PSG3

2 rings

2 rings

Loading...

Loading...