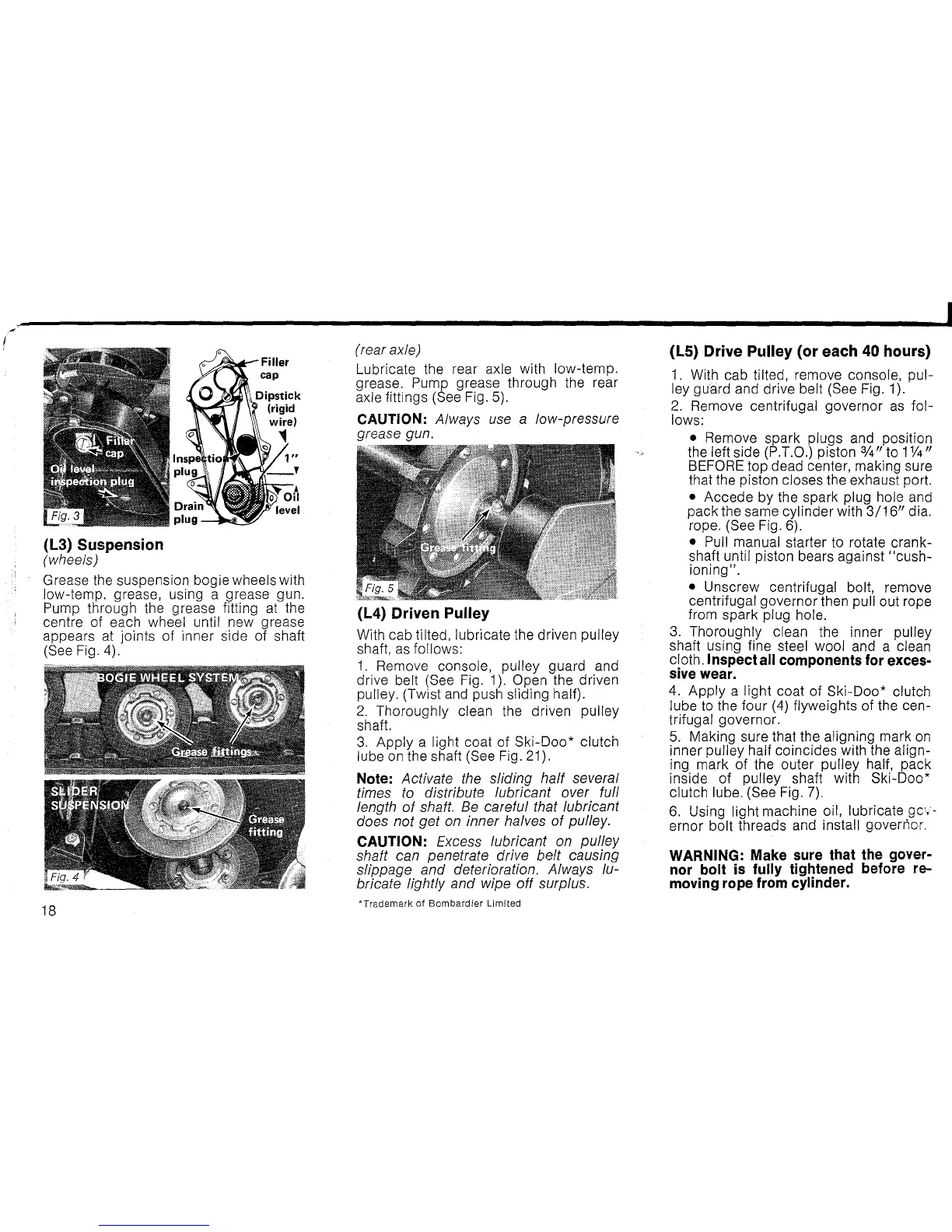

(L3) Suspension

(wheels)

Grease the suspension bogie wheels with

low-temp. grease, using a grease gun.

Pump through the grease fitting at the

centre of each wheel until new grease

appears at joints of inner side

of

shaft

(See Fig. 4).

18

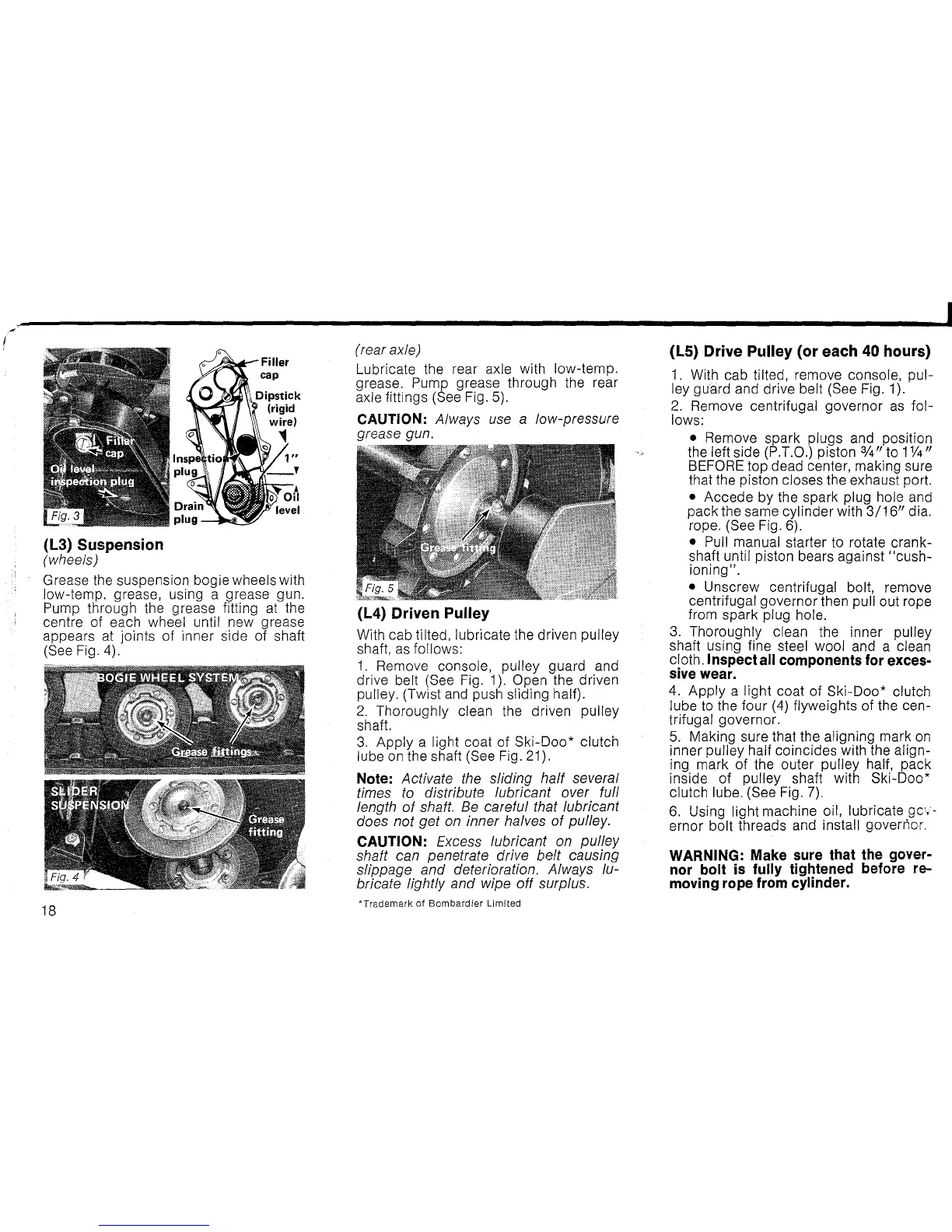

(rear axle)

Lubricate the rear axle with low-tem

p.

grease. Pump grease through the rear

axle fittings

(See Fig. 5).

CAUTION: Always use a low-pressure

grease gun.

(L4) Driven Pulley

With cab tilted, lubricate the driven pulley

shaft, as follows:

1.

Remove console, pulley guard and

drive belt

(See Fig. 1). Open the driven

pulley. (Twist and push sliding half).

2.

Thoroughly

clean the driven pulley

shaft.

3.

Apply

a light coat of

Ski-Ooo*

clutch

lube on the shaft

(See Fig. 21).

Note: Activate the sliding halt several

times

to

distribute lubricant over full

length

of

shaft. Be careful that lubricant

does not get on inner halves

of

pulley.

CAUTION: Excess lubricant on pulley

shaft can penetrate drive belt causing

slippage and deterioration. Always lu-

bricate lightly and wipe off surplus.

'Trademark

of

Bombardier

Limited

(l5)

Drive Pulley (or each 40 hours)

~

1. With cab tilted, remove console,

pul-

ley guard and drive belt (See Fig. 1).

2.

Remove centrifugal

governor

as

fol-

lows:

• Remove

spark

plugs and position

the left side

(P.T.O.) piston

3/4"

to

11f4"

BEFORE top dead center, making sure

that the piston closes the exhaust port.

•

Accede

by

the spark plug hole and

pack

the same

cylinder

with

3/16"

dia.

rope.

(See Fig. 6).

• Pull manual starter to rotate

crank-

shaft until piston bears against

"cush-

ioning".

• Unscrew centrifugal bolt, remove

centrifugal

governor

then

pullout

rope

from

spark

plug hole.

3.

Thoroughly clean the inner pulley

shaft using fine steel wool and a clean

cloth.

I nspect all components for exces-

sive wear.

4.

Apply

a

light

coat of

Ski-Ooo*

clutch

lube to the

four

(4) flyweights

of

the cen-

trifugal governor.

5.

Making sure that the aligning mark on

inner pulley half

coincides

with the align-

ing

mark

of

the outer pulley half, pack

inside of pulley shaft with

Ski-Ooo*

clutch lube. (See Fig. 7).

6.

Using

light

machine oil, lubricate

gc.-

ernor bolt threads and install governor.

WARNING: Make sure that the gover-

nor bolt

is

fully tightened before re-

moving rope from cylinder.

Loading...

Loading...