..

STORING PROCEDURE

It

is

during

Summer,

or

when a vehicle

is

not

in

use

for

a month

or

more, that

proper

storage is a necessity.

"Storage

of

the

Ski-Doo

snowmobile

dur-

ing long periods

of

inactivity consists of

checking and replacing missing

or

worn

parts: Proper lubrication

to

insure that

parts

do

not

become

rusted: Cleaning

items such as

carburetor

of oil gas

mix-

tures, to prevent gum varnish formation

within the carburetor; Battery recharging

(electric

models

only); and in general,

preparing the vehicle so that when the

time

comes

to use the

snowmobile

again

it will start and be in top

condition".

IMPORTANT: The necessity of

proper

storage cannot be overstressed. If you

lack the time

or

proper

tools, be sure to

see your authorized

Ski-Doo

Dealer.

(51) Track

1.

Inspect

track

for

cuts, missing

track

inserts

or

broken rods and make any ne-

cessary replacements.

2.

Lift rear

of

vehicle until

track

is clear

of

ground

then

support

with brace

or

trestle. The

Ski-Doo

snowmobile

should

be stored in such a way that

track

does

not stay in

contact

with

cement

floor

or

bare ground.

Note: Due

to

the material change

of

the

'72 track,

we recommend

to

keep the

spring tension applied. However, the

track should be rotated periodically,

(every

40 days).

(52)

Suspension

(bogie wheels)

1.

Remove the

bogie

wheel sets from

the vehicle.

2.

Remove cross shaft from bogie wheel

set.

Clean

bogie

wheel assembly and

cross shaft

of

dirt

or

rust.

3.

Grease each

bogie

wheel until all old

grease is flushed out.

(See Fig. 4).

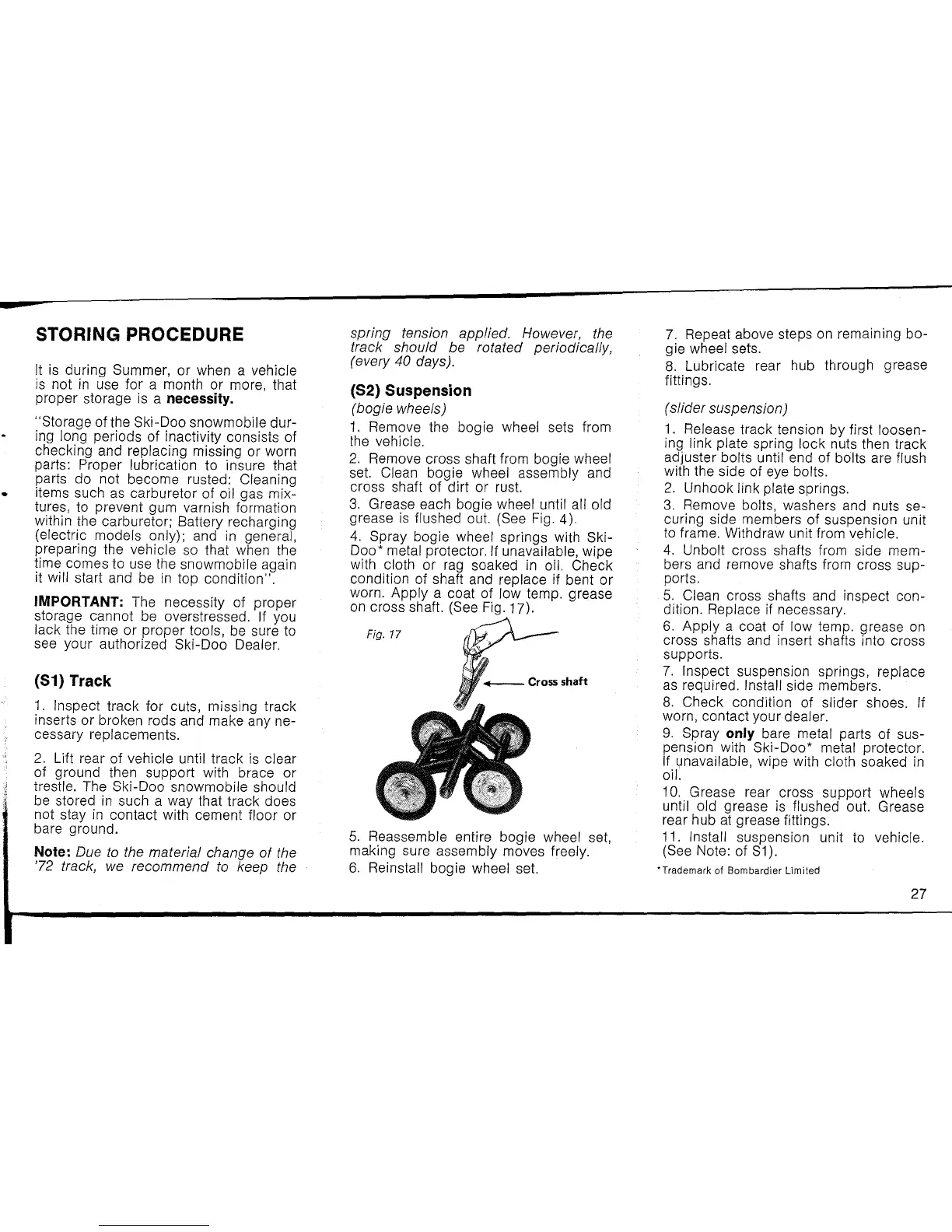

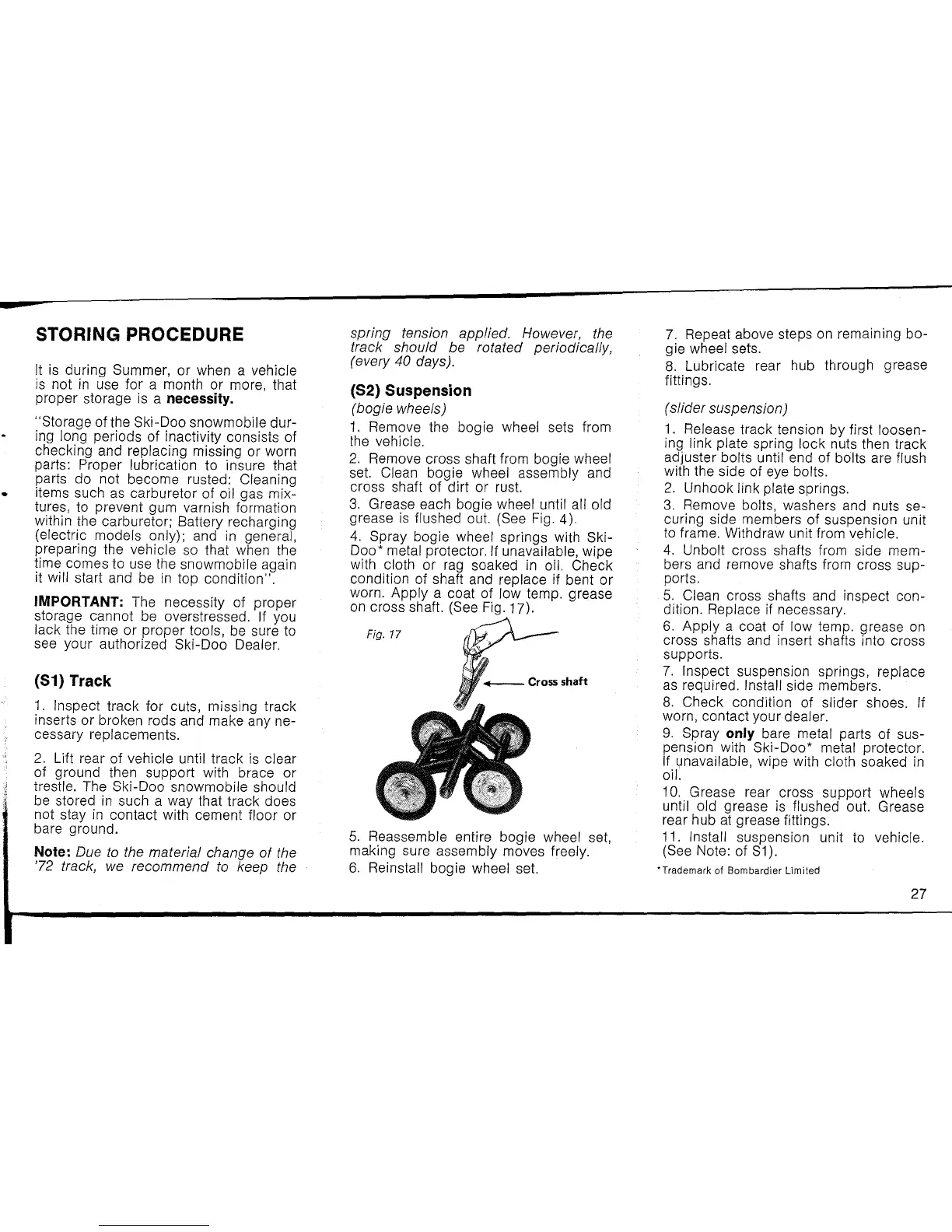

4.

Spray

bogie

wheel springs with

Ski-

000*

metal protector. If unavailable,

wipe

with cloth

or

rag soaked in oil.

Check

condition of shaft and replace if bent

or

worn.

Apply

a coat

of

low

temp. grease

on cross shaft.

(See Fig.

17).

5.

Reassemble entire

bogie

wheel set,

making sure assembly moves freely.

6.

Reinstall bogie wheel set.

7.

Repeat above steps on remaining

bo-

gie

wheel sets.

8.

Lubricate rear hub through grease

fittings.

(slider suspension)

1.

Release

track

tension

by

first

loosen-

ing link plate spring

lock

nuts then

track

adjuster

bolts until end

of

bolts are flush

with the side of eye bolts.

2.

Unhook

link plate springs.

3. Remove bolts, washers and nuts se-

curing side members

of

suspension unit

to frame. Withdraw unit from vehicle.

4.

Unbolt cross shafts from side

mem-

bers and remove shafts from cross sup-

ports.

5.

Clean cross shafts and inspect

con-

dition. Replace if necessary.

6.

Apply

a coat of

low

temp. grease on

cross shafts and insert shafts into cross

supports.

7.

Inspect suspension springs, replace

as required. Install side members.

8.

Check

condition

of

slider

shoes. If

worn, contact

your

dealer.

9.

Spray only bare metal parts

of

sus-

pension with

Ski-Doo*

metal protector.

If unavailable,

wipe

with cloth soaked in

oil.

10. Grease rear cross

support

wheels

until old grease is flushed out. Grease

rear hub at grease fittings.

11. Install suspension unit to vehicle.

(See Note: of S1).

'Trademark

of Bombardier Limited

27

Loading...

Loading...