5

BR'EAKIN~i IN: NEW

CHAIN

,.

IfARNING: DO NOT ATTEMPT TO ADJUST CHAIN WITH SAW

FUJNNING.

1. A. SQUEEZE THE TRIGGER JUST ENOUGH TO LET

U-lAIN ROTATE FOR ABOUT

2

MINUTES ..

B.

PUMP OIL TO THE BAR AND CHAIN, use oil pro-

fusely during this break-in stage.

3. TURN THE SAW OFF AND CHECK TO SEE IF THE

TIE LINKS ARE SNUG AGAINST THE BAR. IF NOT,

LOOSEN. THE COVER NUT-

ANO

RESET THE CHAIN

. TENSION. ',.. . -

WARNING: MAKE SURE

THE'

'CLUTCH COVER 'NUTS

ARE TIGHTENED SECURE.LY

BEFORE

CUTTING~J~D

AFTER EACH ADJLJ~TMENT_' " ' • _..•.

:~t.'

'f

.J'. "~ -. ,_,

During the first half to one hour of operation while the chain,

bar and sprocket are wearing in together, chain slack will

develope. Stop cutting every five to ten minutes and check

the chain tension. BE SURE TO SHUT OFF SAW. Always

reset tension when it is incorrect. TOO MUCH TENSION

creates excessive heat and wear, robs power and overloads

the engine. TOO LITTLE TENSION allows the chain to ham-

mer and chatter during operation, damaging the chain, bar

groove and sprocket ..

ADDITIONAL TENSJON CHECK: The chain should coast

slightly after throttling' down 'the

enqine ,

If

the chain stops

instantly, it is an indication that the chain is too tight.

NOtE': A loose 'chain is "normally caused by Stretch and

not a' loosecover nut.

'.

t~ -; ; - ):

'.. ADJU.S.TJNG

:1:~~ARff.~~LY

'i~,f{~

THE'

;'AJ.:.:,_.~NR·~~A-.Q~i,.$fl:rn~9('.~f~~~

.. DLES ALL THE WAY IN (CLOCKWISE) ANTI

.GJ:NJ..LY

,~ ,-,,~~ •. s- ;.;.

r ,'

SEAT BOTH NEEDLES. Forcing the needles into seat can

cause damage and make the carburetor unadjostable and

require replacing it.

2.

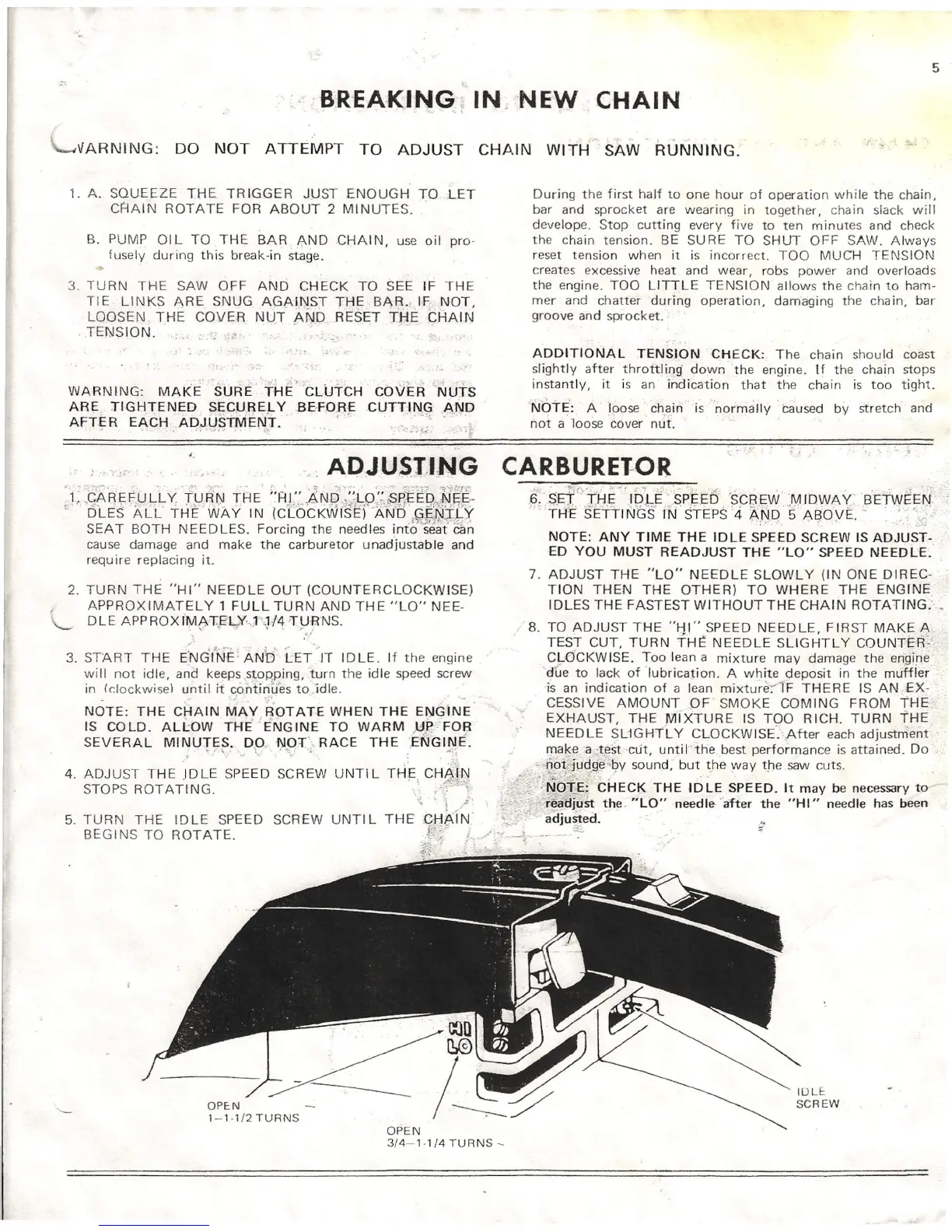

TURN THE "HI" NEEDLE OUT (COUNTERCLOCKWISE)

APPROXIMATELY

1

FULL TURN AND THE "LO" NEE-

DLE APPROX

i'Ty1&T.Jf4Y'J·.]/~

""VflNS.

,

...

/

3. START THE E:~G(Nf::

ANT)

LET"'IT IDLE. If the engine

will not idle, and keeps stoppinq, turn the idle speed screw

in Ir:lockwisel until it co.ntinues to idle.

'"

~:.

NOTE: THE CHAIN MAY ROTATE WHEN THE ENGiNE'

IS COLD. ALlOW THE 'E'NGINE TO WARM .kl_~-'-FOR

SEVERAL MINUTES, DO, NOTo. RACE THE.E-NGINE·_

':

.

'.

,.

\:

'

....

..,;;

.•.

;

4.

ADJUST THE

'10

LE SPEED SCREW UNTI L THE CHA'(N

STOPS ROTATING. ','

/i~~"-{'

<3, '')

s-

5. TURN THE IDLE SPEED SCREW UNTIL THE CH~IN'

BEGINS TO ROTATE.

J'~' .

¥:~:!

OPEN

1-1.1/2TURNS

OPEN

3/4-1·1/4 TURNS-

CARBURETOR

K'

SEjo'JH,E,-"

!P.-!J:,:~p:~E6.

'$qn=.w

.J'0IDWAY· 'BdwEE~

'''THE SETTINGS IN STEPS

'4

AN.D

5

AB·OVE.'

e ;

<:

J . :" '" .', "-.' • • • '. ~

\~r::

NOTE: ANY TIME THE IDLE SPEED SCREW IS ADJUST-

ED YOU MUST READJUST THE "LO" SPEED NEEDLE.'

7.

ADJUST THE "LO" NEEDLE SLOWLY (IN ONE DIREC-

TION THEN THE OTHER) TO WHERE THE ENGINE

IDLES THE FASTEST WITHOUT THE CHAIN ROTATING:' .•

8.

TO ADJUST THE "HI" SPEED NEEDLE, FIRST MAKE

A

TEST CUT, TURN

fH~

NEEDLE SLlGHTL Y COUNTER:: .

CL6cKWISE. Too lean a mixture may damage the engine'

'dlJe to lack of 'lubr ication. A white deposit in the muffler

is an indication of a lean rnixturer Tf THERE IS AN

EX-

CESSIVE AMOUNT OF SMOKE COMING FROM THE

EXHAUST, THE MIXTURE IS TOO RICH. TURN THE

NEEDLE SL1GHTLY CLOCKWISE·.··.After each adjustment -

make a~teSt

cut, unti

lthe best performance is attained. Do

. ". ~~~~l~~g~-'by sound; but the way the saw cuts.

.::/.,{:'N.().tE~··d-iECK THE IDLE SPEED. It may be necessary to

':- ':. ;::·jeatljuSt the. "LO" needle "after the "HI" needle has been

:~;:':'~ adju~ed. . "

r" .,

.

.~-

(OLE

SCREW

Loading...

Loading...