– Install piston with commercially available piston ring tension‐

ing strap, check installation position ⇒ page 71 .

– Install conrod bearing cap, check installation position Pos.

-2- ⇒ page 69 .

– Install cylinder head ⇒ page 80 .

– Install sump top part ⇒ page 132

Tightening torques

♦ Conrod with conrod bearing cap

⇒ “4.1 Piston and conrod - Summary of components”,

page 69

4.3 Checking piston and cylinder bore

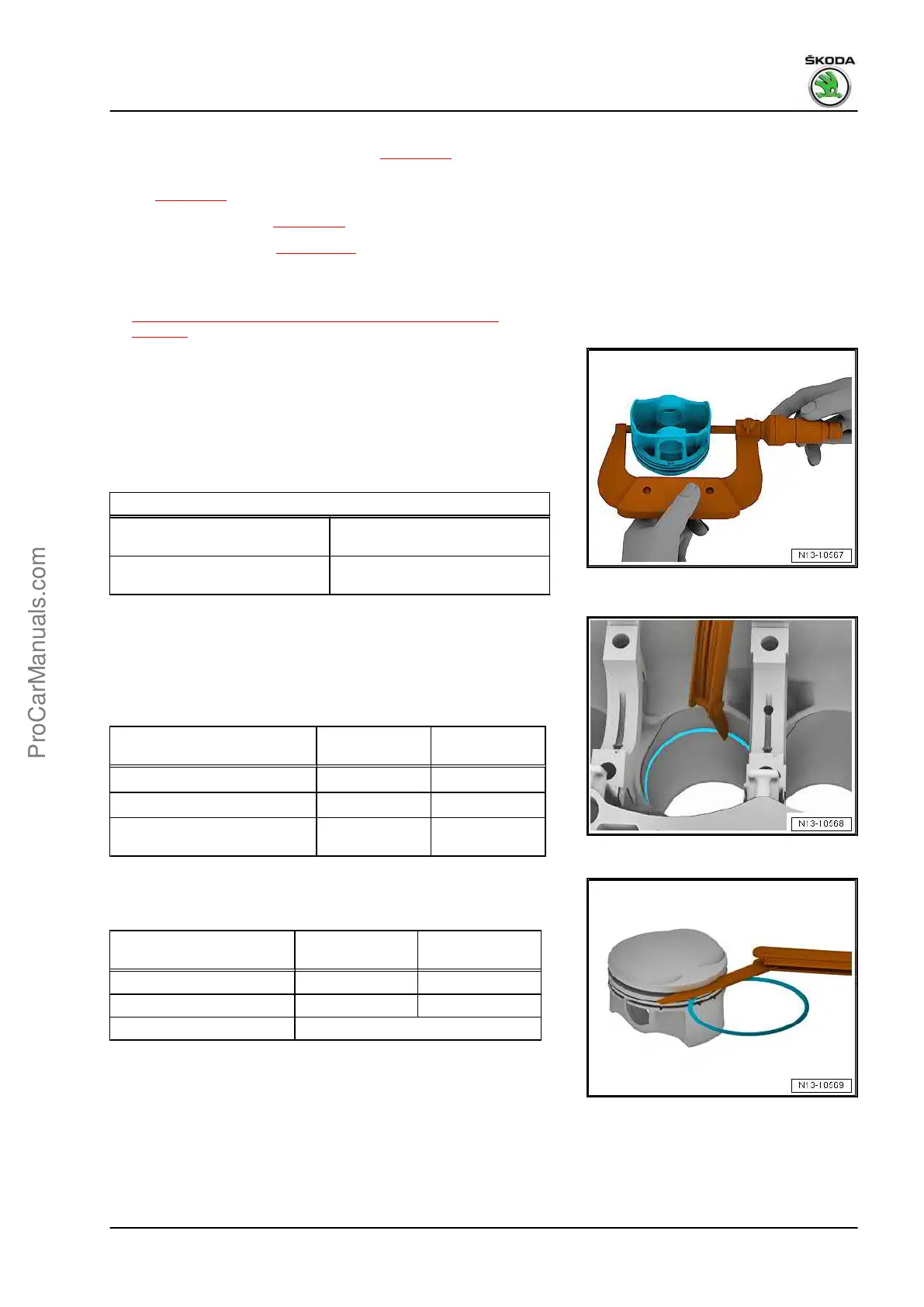

Inspecting pistons

– Using an external micrometer, measure pistons approx.

10 mm from the lower edge of skirt, at 90° to the piston pin

axis.

• Maximum deviation from nominal dimension: 0.04 mm.

Piston ∅ mm

Nominal dimension without lu‐

bricating coating

76.455 + 0.009

– 0.009

Nominal dimension with lubri‐

cating coating

76.485 + 0.017

– 0.017

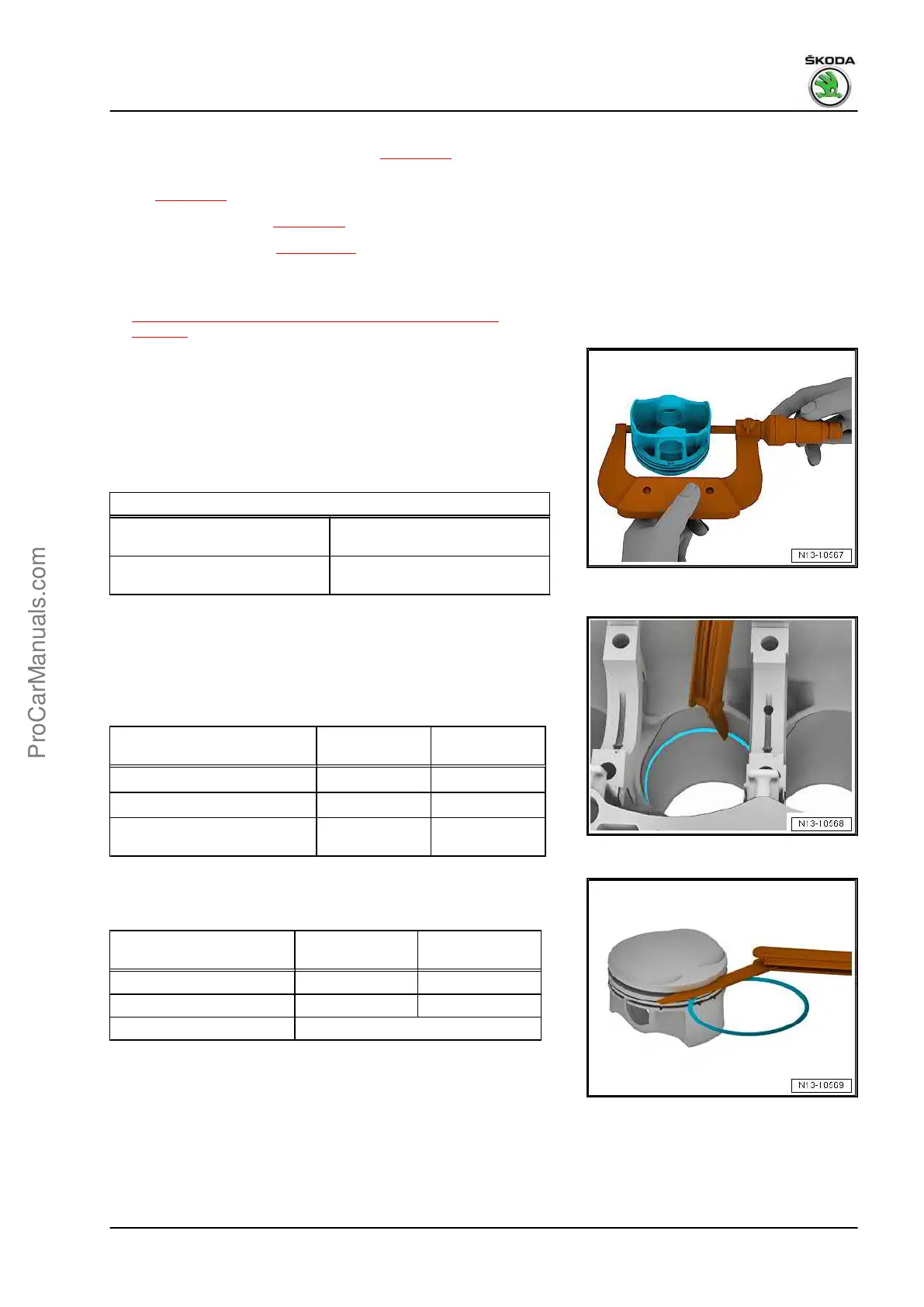

Measure piston ring end gap

– Insert ring at right angles from above down into lower cylinder

opening, about 15 mm away from edge of cylinder.

– Push a commercially available feeler gauge into the piston ring

opening to check the end gap.

Piston ring new

mm

Wear limit

mm

1. Compression ring

0.20

+ 0.15

1.0

2. Compression ring

0.40

+ 0.20

1.0

Oil scraper rings 3 part

0.20

+ 0.50

no wear indica‐

tion possible

Measure piston ring vertical gap

– Clean before inspecting the annular groove of the piston.

Piston ring new

mm

Wear limit

mm

1. Compression ring 0.04 … 0.08 0.15

2. Compression ring 0.03 … 0.07 0.15

Oil scraper rings (3 part) cannot be measured

Octavia III 2013 ➤ , Octavia III 2014 ➤ , Yeti 2010 ➤ , Yeti 2011 ➤

1.6/81 kW MPI engine - Edition 06.2014

4. Pistons and conrods 73

ProCarManuals.com

Loading...

Loading...