General Maintenance

Before attempting any repair work, disconnect battery by turning main power disconnect switch to

“ ” off position. Preventive maintenance is the easiest and least expensive type of maintenance.

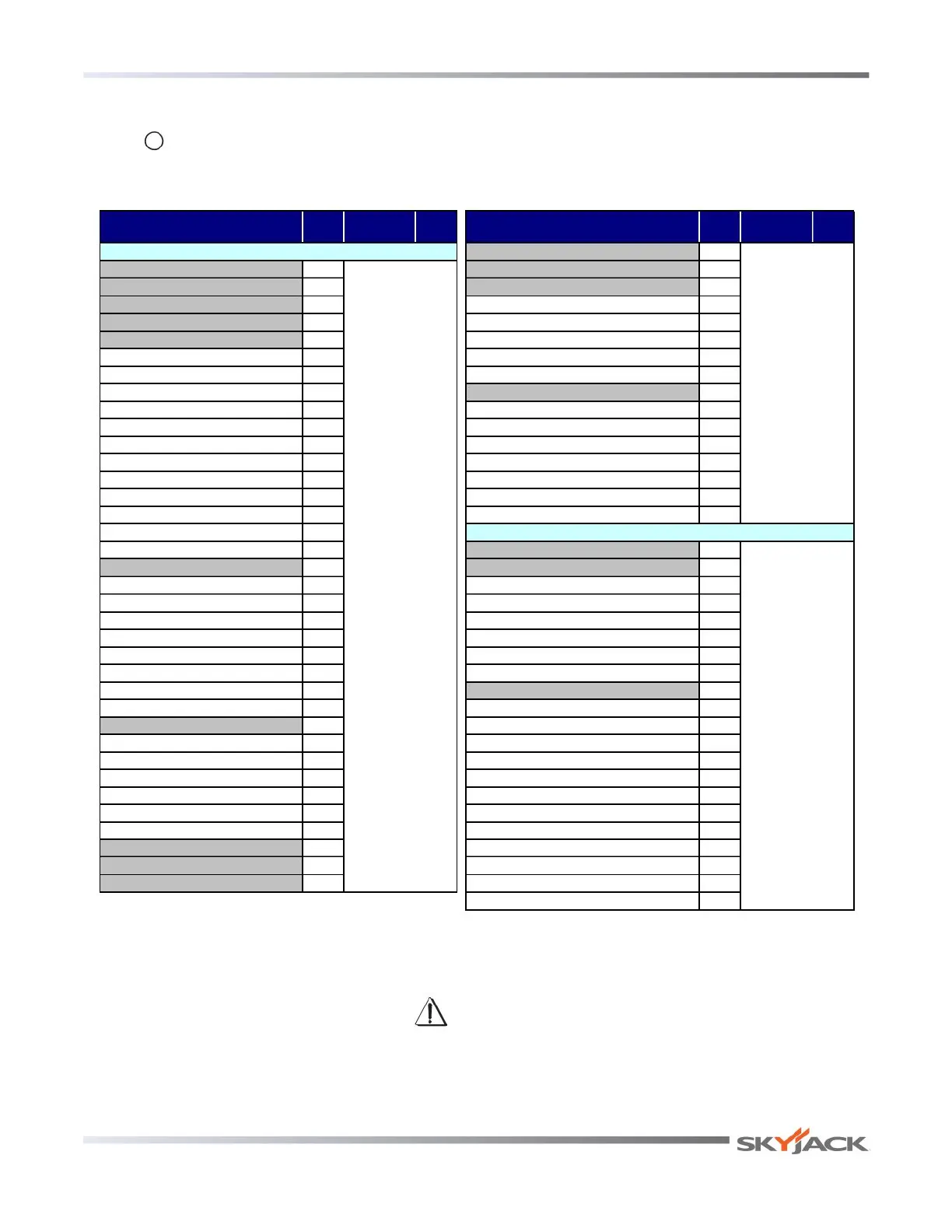

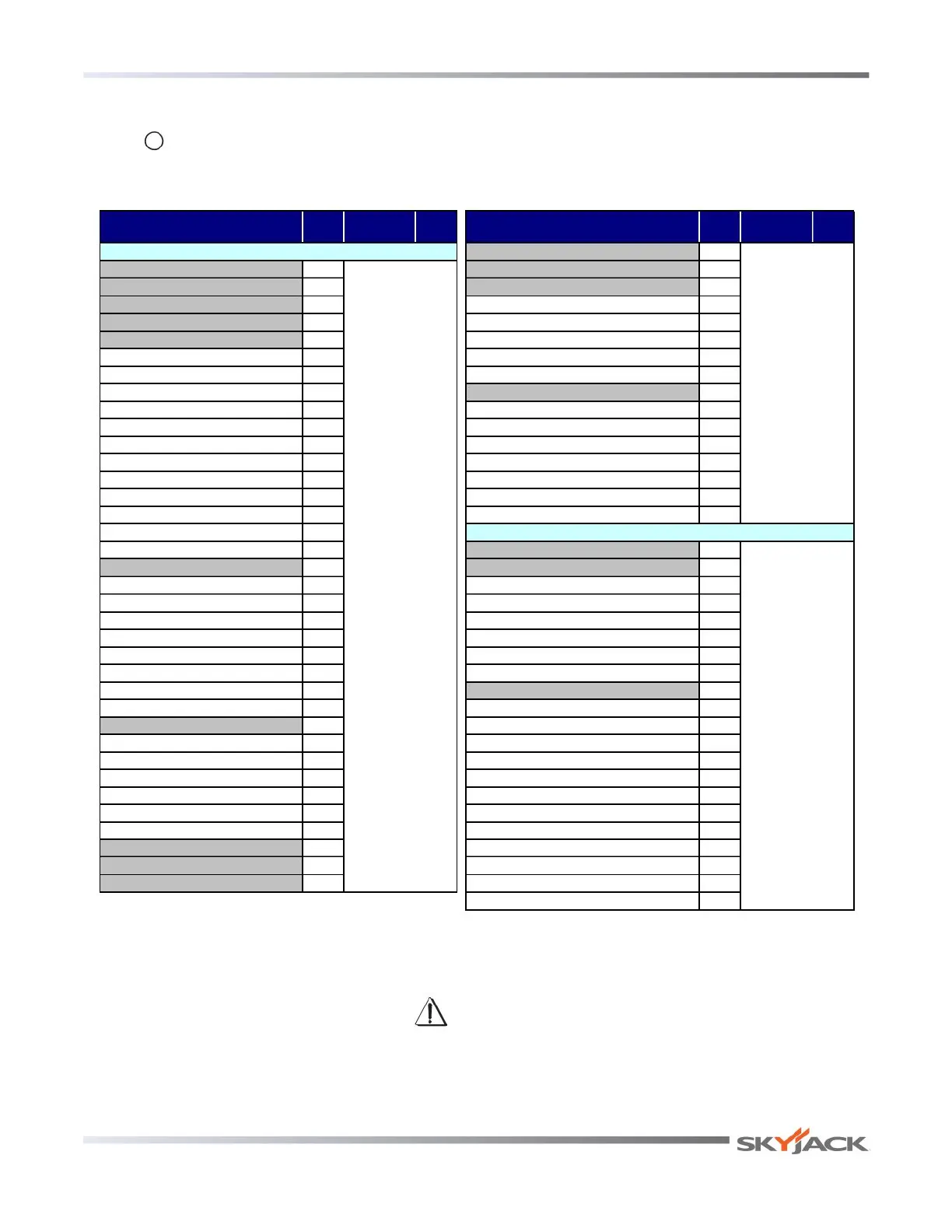

Table 4.7 Maintenance and Inspection Schedule

Frequency

Daily

3 months or

150 hours

Yearly

Frequency

Daily

3 months or

150 hours

Yearly

Rotary Actuator A

Labels A Jib (If Equipped) A

Electrical A Boom A

Limit Switches A Cylinders A

Hydraulic A Wear Pads A

Engine Compartment Hoses A

Main Power Disconnect Switch A Power Track A

Battery A Cables (61T/66T) A

Swing Drive Motor A Optional Equipment/Attachments

Turret Rotation Gear A Hydraulic Generator (If Equipped) A

Rotary Manifold A Battery Warmer/Hydraulic Oil Heater (If Equipped) A

High Pressure Filter (40T/45T) A Welder (If Equipped) A

Hydraulic Pumps A Work Light (If Equipped) A

Muffler and Exhaust A Flashing Amber Light (If Equipped) A

Engine Pivot Tray A Glazier Tray (If Equipped) A

Engine Oil Level A Arctic Weather Package (If Equipped) A

Engine Air Filter A Function Tests

Fuel Leaks A Test Main Power Disconnect Switch A

Control Compartment Base Control Console

Base Control Console A Test Emergency Stop A

Hydraulic Tank A

Test Function Enable Switch & All Boom Functions

A

Hydraulic Oil A Test Platform Self-leveling A

Hydraulic Return Filter A Test Emergency Power A

Brake and Main Manifolds A Test Base/Off/Platform Switch A

Emergency Power Unit A Test Positive Air Shutoff (If Equipped) A

Fuel Tank A Platform Control Console

Fuel Leaks A Test Footswitch A

Base Test Emergency Stop A

Turret Transportation Lock A Test Steering A

Drive Axle A Test Driving Function A

Oscillating Cylinder Assembly A Test Driving Speed A

Steer Cylinder Assembly A Test Emergency Power A

Tie Rod A Test Horn A

Wheel/Tire Assembly A Test Brakes A

Manuals A Test Manual Platform Leveling A

Platform Assembly A Test Differential Lock Switch A

Platform Control Console A Test Oscillating Axles A

Test Cables (61T/66T) A

60559AL-ANSI

A - Perform Visual and Daily Maintenance Inspections & Functions Test. Refer to Section 2.3 and Section 2.4 of this manual.

B - Perform Scheduled Maintenance Inspection. Refer to Service & Maintenance manual.

* - Maintenance must be performed only by trained and competent personnel who are familiar with mechanical procedures.

† - Refer to Skyjack's website @ www.skyjack.com for latest service bulletins prior to performing quarterly or yearly inspection.

Visual and Daily Maintenance Inspections

B*†

B*†

B*†

WARNING

Use original or manufacturer-approved parts and components for aerial platform.

SJ 40T & SJ 45T

SJ 61T & SJ 66T

Page 75

Loading...

Loading...