Page 12

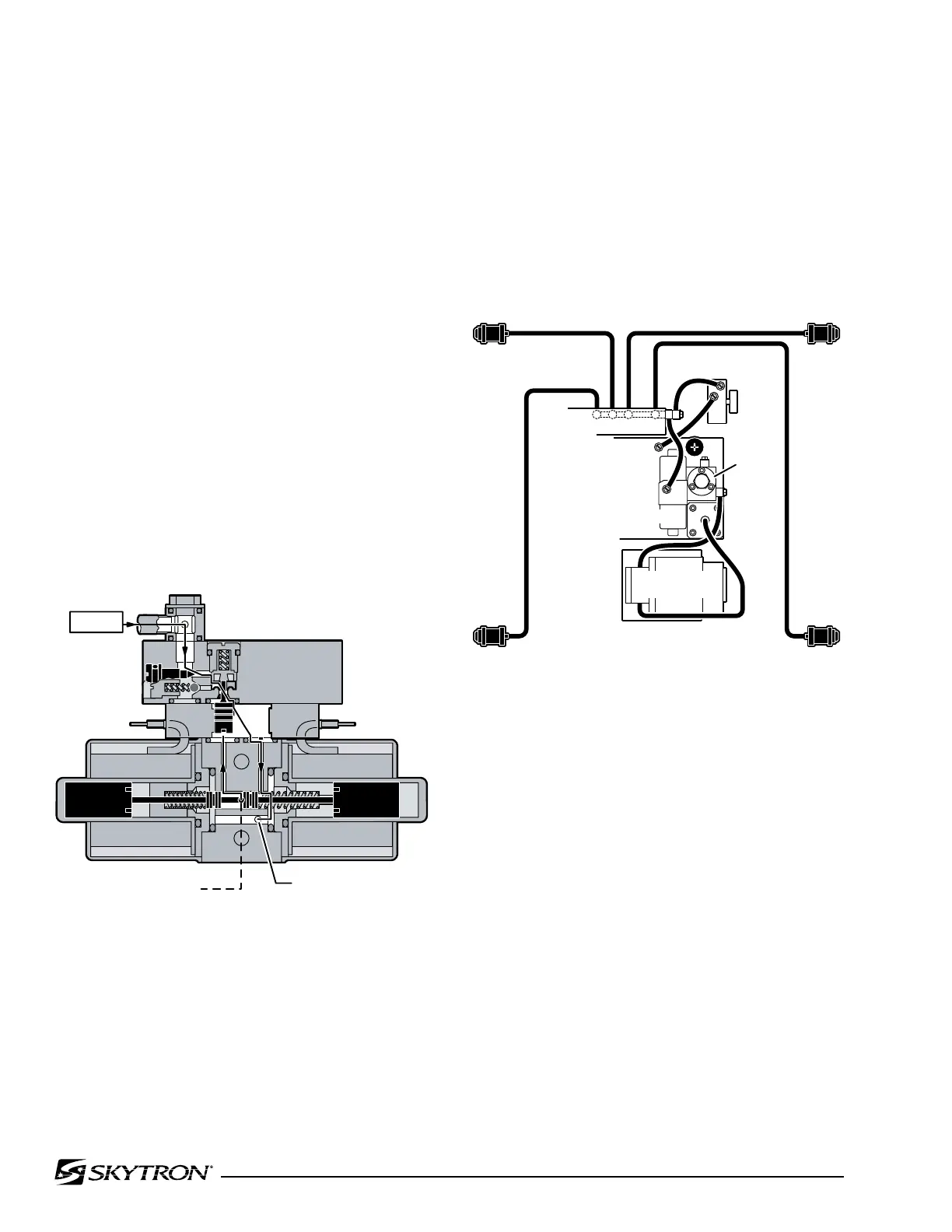

2. 3-way (single check valve type) mini-valve.

3. Manually controlled emergency brake re-

lease.

4. Plumbing terminal, flexible hoses, copper

lines and "O" rings.

5. Portions of the electrical system.

Figure 1-15. Brake System Block Diagram

Each corner of the cast-iron table base has a hydrau-

lic brake cylinder. These single action cylinders are

hydraulically connected in parallel to the mini-valve

and all four are activated together. It is normal for

one corner of the table to raise before the others

due to the weight distribution of the table.

An electronic timer in the relay box is activated when

any function on the pendant control is pushed

momentarily. The pump/motor and brake system

mini-valve are activated and the brake cylinders

are completely set. The electronic timer runs for

approx. 8-10 seconds.

The brakes are released by pushing the BRAKE

UNLOCK button momentarily. An electronic timer in

the relay box activates the brake function hydraulic

mini-valve and pump/motor.

Figure 1-14. Elevation Return Circuit

f. Brake System

The brake system consists of the following compo-

nents: (figure 1-15)

1. Single action slave cylinders (4 each).

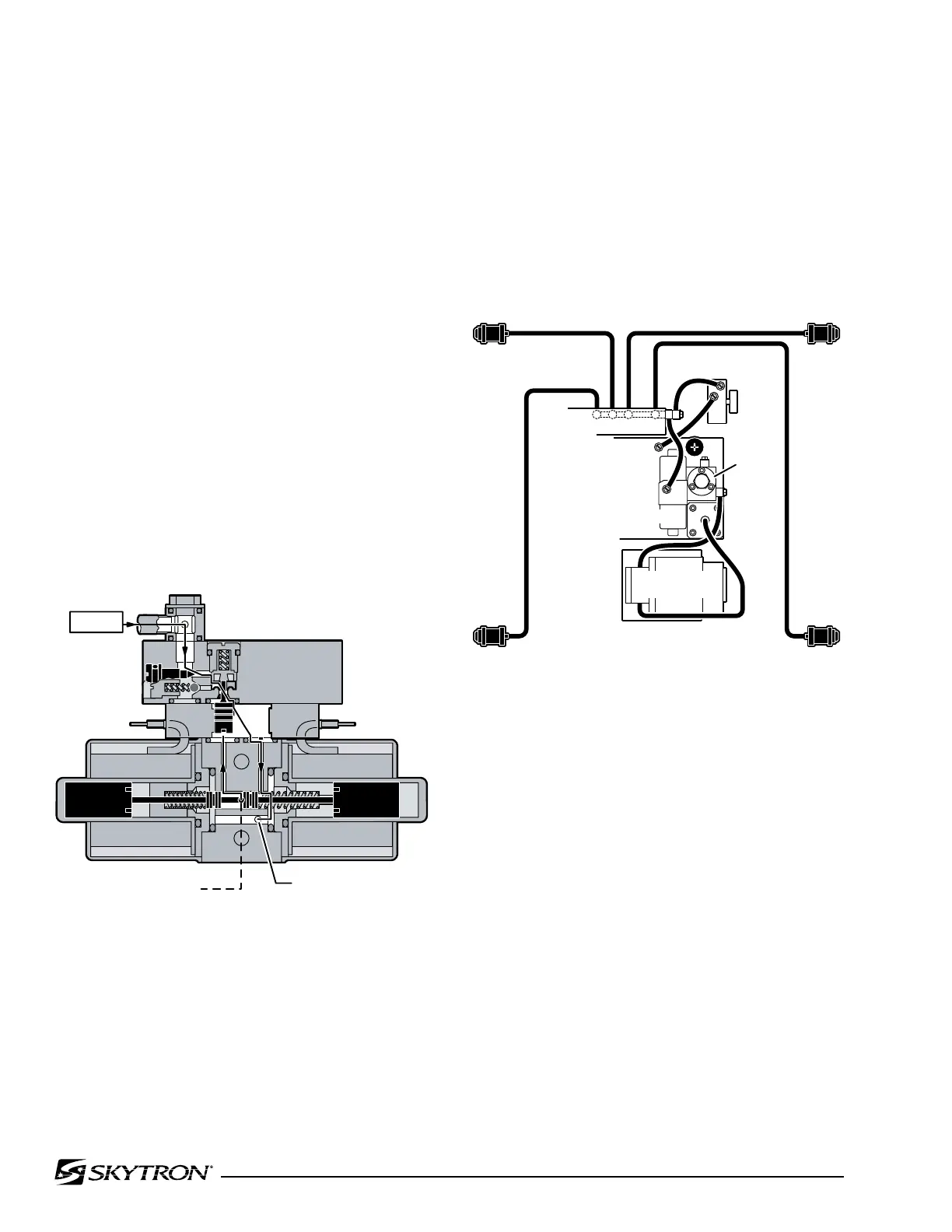

e. Elevation Cylinder Return Circuit

A three-way (single check valve type) mini-valve

controls both the elevation and return circuits. The

elevation circuit operation within the mini-valve is

identical to the operation of the four-way valves

previously described (inlet pressure opens the

check valve allowing the oil to enter the cylinder). In

the return position, inlet pressure pushes the pilot

plunger up and opens the return check valve. See

figure 1-14. The open check valve allows a path

for the oil in the elevation cylinder to return to the

reservoir. When the pilot plunger valve is opened,

the continuing pump pressure opens the pres-

sure relief valve which provides a return oil path

to the reservoir.

The mini-valve used in the elevation circuit contains

only one check valve (all four-way mini-valves use

two check valves). The check valve is used to trap

the oil in the elevation cylinder thereby supporting

the table top. When the top is being lowered the

check valve is mechanically held open by the pilot

plunger through pump pressure.

041905.029

TO RESERVOIR THROUGH

PRESSURE RELIEF VALVE

INLET

RETURN TO

RESERVOIR

041905.028

MOTOR/PUMP

ASSEMBLY

PLUMBING

TERMINAL

BRAKE

BRAKE

BRAKE

BRAKE

EMERGENCY

BRAKE RELEASE

PRESSURE

RELIEF

VALVE

BRAKE

MINI-VALVE

Loading...

Loading...