Page 14

Figure 1-19.

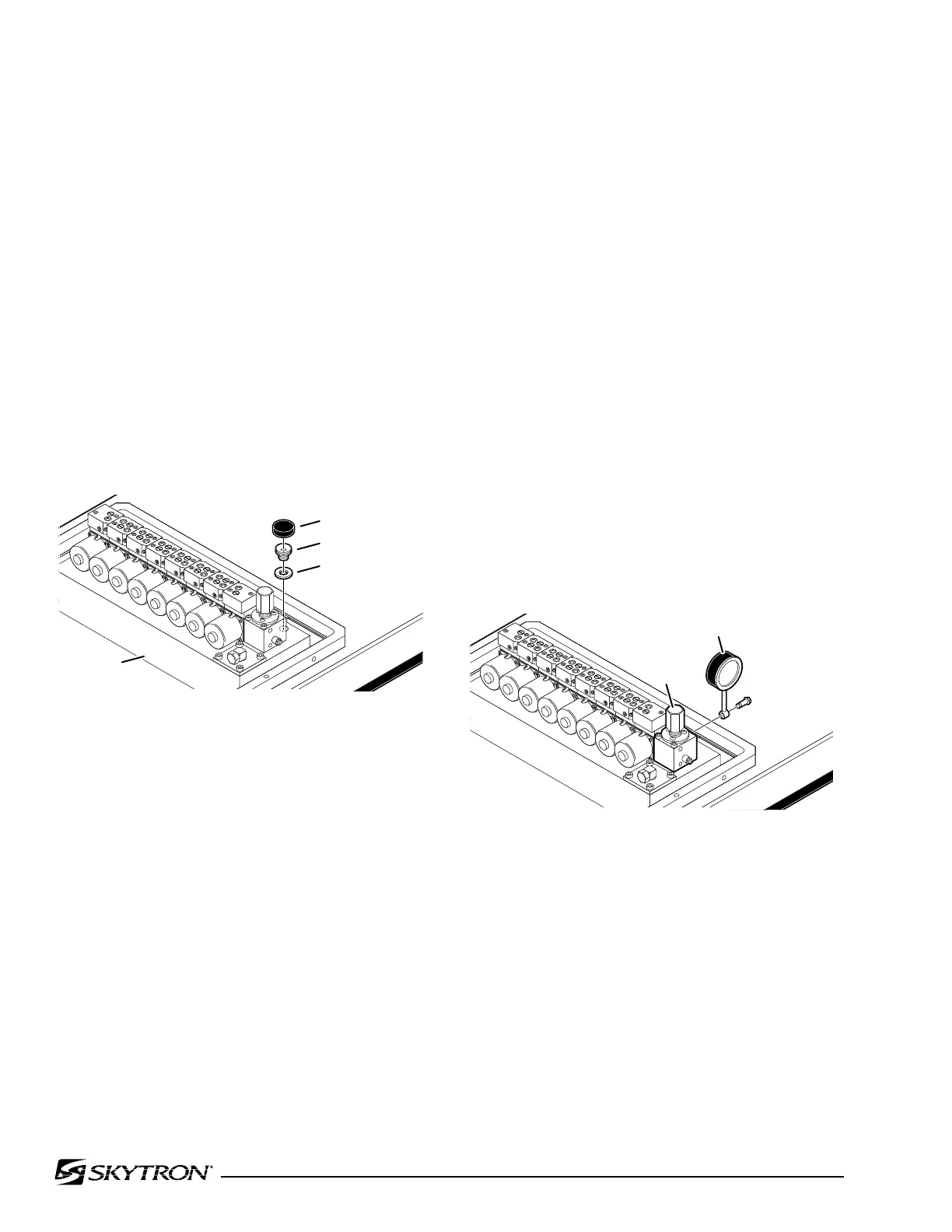

2. Raise the table top until the piston reaches

the end of its stroke and stalls. Observe reading

on pressure gauge and turn the adjustment nut

(clockwise to increase oil pressure, counterclock-

wise to decrease) until desired reading is obtained.

Pressure should be 8MPA (80KG/CM

2

-1138 PSI).

An erratic reading and/or inability to adjust to the

recommended setting may indicate the need for

replacement of the pressure relief valve.

1-3. Hydraulic Adjustments

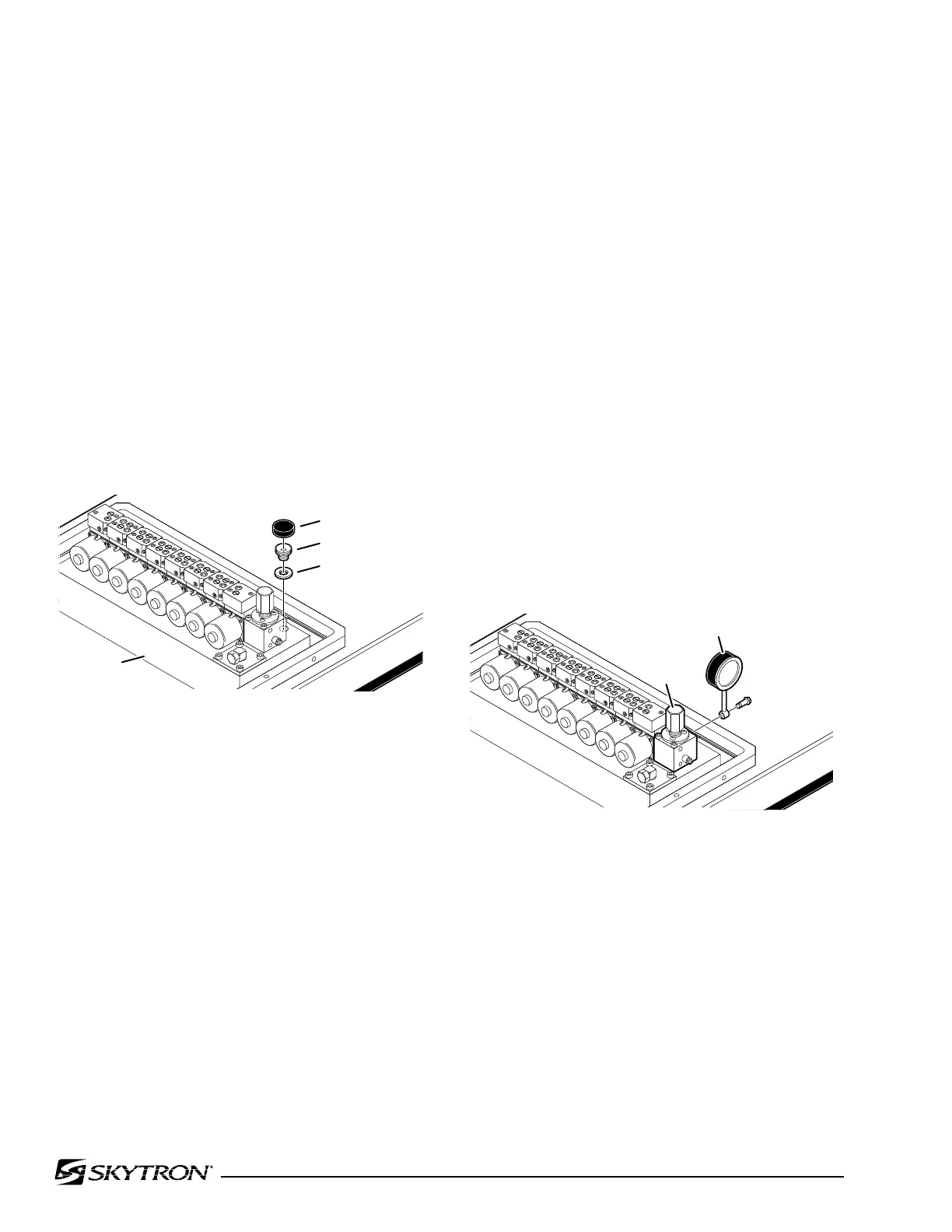

a. Fluid Level.

The fluid level should be approximately 1/2" below

the filler hole or gasket surface. If additional fluid

is needed, remove the filler vent cap with a phillips

screwdriver and add fluid through this opening

using a funnel. See figure 1-18.

NOTE

The elevation cylinder should be com-

pletely down, the brakes released and all

the other control functions in their neutral

position when checking oil level.

NOTE

Whenever a hydraulic line or component

is replaced, bleed the air out of the line

using the pump pressure by activating

the function before making the final con-

nection. Then operate the function until

it stalls in both directions.

c. Pressure Relief Valve

The pressure relief valve is adjusted by turning

the adjustment nut until the desired pressure is

reached.

To adjust:

1. Remove the blind cap and attach a hydraulic

pressure gauge to the main oil galley using a 6mm

plumbing bolt. See figure 1-19.

Figure 1-18.

The type of oil that should be used is SKYTRON P.N.

D6-010-90 or equivalent. This is a very high quality

hydraulic oil. The table requires approximately two

quarts of oil to operate properly. Excercise caution

when determining equivalance to avoid damage to

the hydraulic system.

b. Bleeding The Hydraulic System

To purge the air from the hydraulic system, oper-

ate each function back and forth at least two or

three times.

041905.032

FILLER CAP

FITTING

GASKET

OIL TANK

RESERVOIR

041905.033

PRESSURE

RELIEF

VALVE

PRESSURE

GAUGE

PLUMBING

BOLT

Loading...

Loading...