TR Series

5

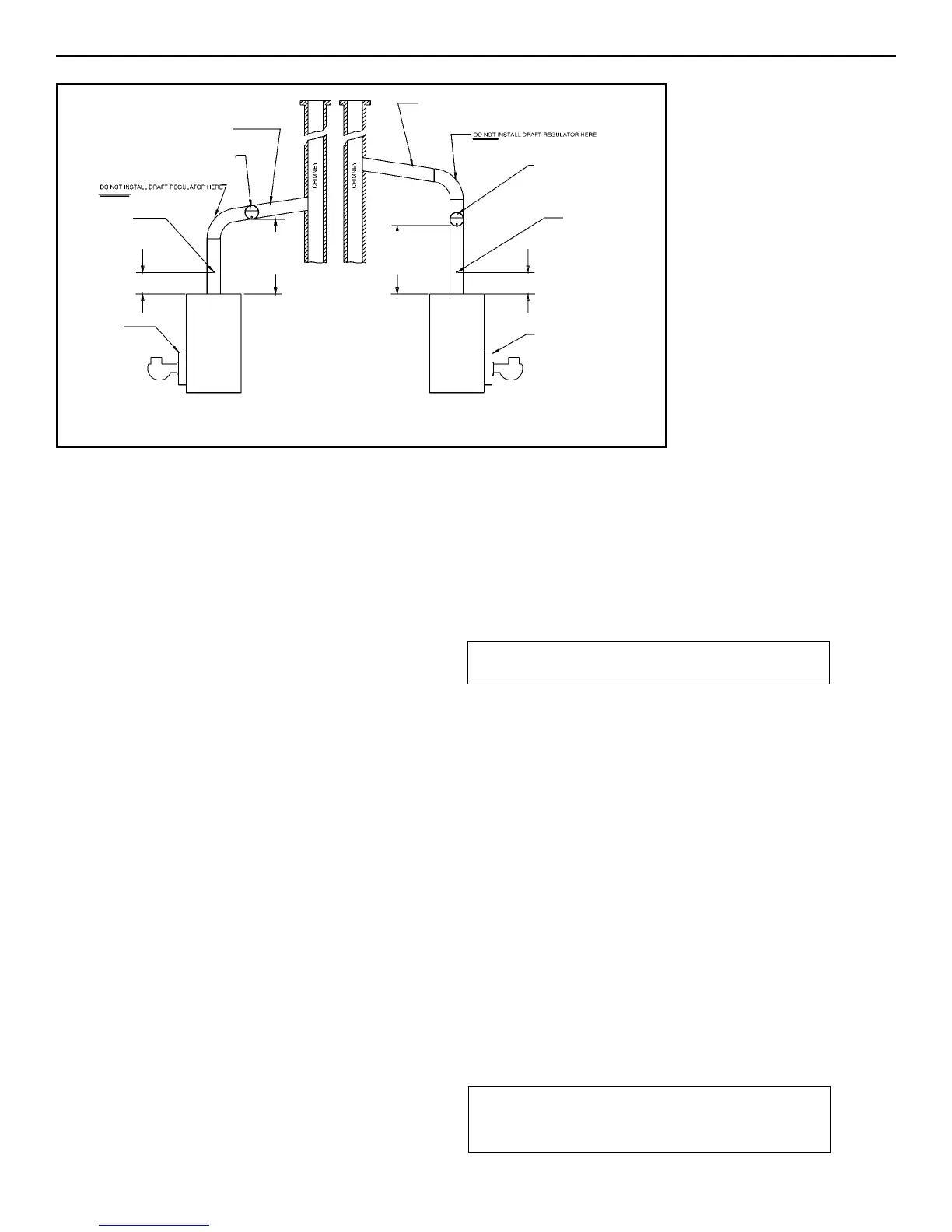

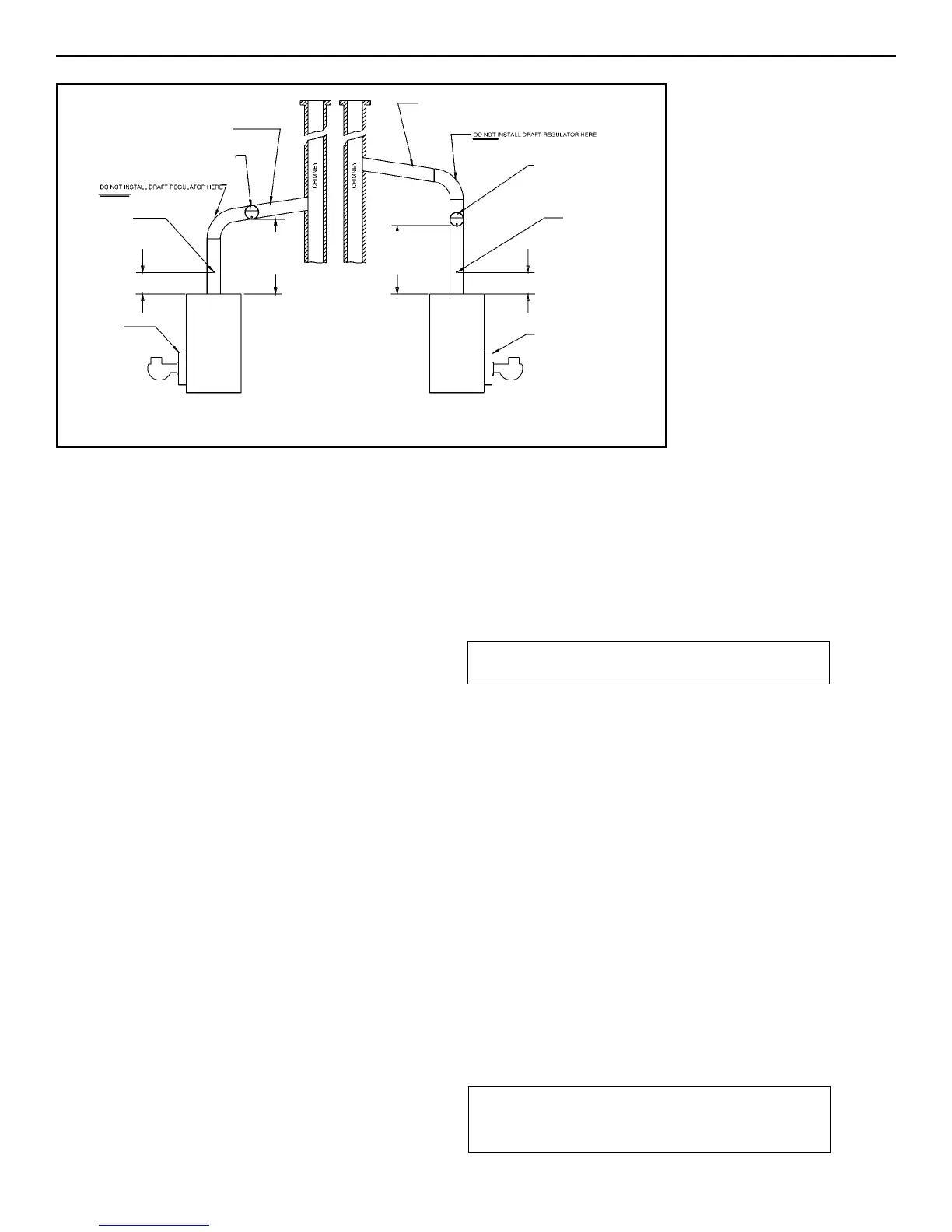

Figure 3.

Barometric Draft

Regulator

Location

PITCH UP

21 mm/m (1/4" per linear foot)

Drill 6 mm (1/4")

HOLE TO

MEASURE

DRAFT, SMOKE,

CO

2

and stack

temperature

PITCH UP

21 mm/m (1/4" per linear foot)

457 mm

(18")

MINIMUM

229 mm (9")

DRILL 6 MM (1/4")

HOLE TO

MEASURE DRAFT,

SMOKE, CO

2

AND

STACK

TEMPERATURE

MAINTAIN 0.5

MM (0.02")

W.C. DRAFT

(OVER-FIRE)

MAINTAIN 0.5

MM (0.02")

W.C. DRAFT

(OVER-FIRE)

BAROMETRIC DRAFT REGULATOR

INSTALLED ON HORIZONTAL CONNECTION

BAROMETRIC DRAFT REGULATOR

INSTALLED ON VERTICAL RISE

229 mm (9")

457 mm

(18")

MINIMUM

CHIMNEY REQUIREMENTS

A. The chimney must be constructed in accordance with all

local applicable codes and the National Board of Fire

Underwriters. See boiler models and rating table shown on

page 2 for chimney sizes.

B. Check chimney condition.

Existing chimneys and stacks may have deteriorated; without

repairs their use would be hazardous. Before connecting to an

old chimney or stack:

1. Clean it.

2. Inspect it thoroughly.

3. Remove obstructions.

4. Replace worn sections of metal stacks.

5. Seal bad masonry joints.

6. Repair damaged linings.

C. Where more than one appliance vents into a common chimney,

the area of the common Breaching should at least equal the

area of the largest appliance flue plus 50% of the additional flue

areas.

D. Breaching area must not be reduced at connection into chim

ney. Breaching must be inserted into, but not beyond, inside of

chimney liner.

E. Chimney height shall extend at least 1 m (3 feet) above where it

passes through the roof of the building, and at least 0.5 m (2

feet) above any ridge within 3 m (10 feet) of the chimney.

F. The use of a vent cap, where permitted by code, gives addition

al protection against adverse wind conditions and precipitation.

G. Flue Connection: Connect flue pipe between top of boiler and

chimney. Horizontal sections of flue pipe must be pitched

upward to the chimney at least 21 mm/m (

1

/4" per foot). Flue

must be inserted into, but not extend beyond, the inside wall of

the chimney flue. Install draft regulator in flue pipe, as shown in

figure 3.

BLOCKED VENT SAFETY SWITCH

All Intrepid TR Series boilers must be installed with a Blocked

Vent Safety Switch. The Blocked Vent Safety Switch will

detect spillage of flue gases due to a blocked vent or

inadequate draft.

The Blocked Vent Safety Switch supplied with all Intrepid TR

Series boilers must be installed on the barometric damper.

Refer to the manufacturers instructions provided with the

Blocked Vent Safety Switch for installation, location

instructions.

The Blocked Vent Safety Switch is to be FIELD wired, see

wiring diagrams, into the line voltage connection being wired

into the junction box, so the Blocked Vent Safety Switch

breaks power supply to the boiler shutting it down in the

event of a spillage.

IMPORTANT: The Blocked Vent Safety Switch must be wired

in accordance with The National Electrical Code, the

Installation of Oil Burning Equipment, CSA B139. The

installation must also conform to any applicable local codes,

the manufacturer's instructions, the requirements of this

Slant/Fin manual, and any authority having jurisdiction.

Where there is any difference the more stringent requirement

shall govern.

Check the operation of the Blocked Vent Safety Switch:

A: Block chimney or vent pipe.

B: Adjust thermostat to call for heat.

C: Allow approximately two minutes for the system to back up

and the burner to shut down.

D: Perform steps B and C again.

AIR SUPPLY AND VENTILATION

(see CSA B139, latest edition, Section 7)

Sufficient air for combustion and ventilation in the boiler room

must be provided. Failure to do this will result in poor combus

tion, heavy sooting and health hazards.

BAROMETRIC DRAFT

REGULATOR

BAROMETRIC DRAFT

REGULATOR

CAUTION: DISCONNECT ELECTRICAL POWER WHEN

WIRING.

CAUTION: AN OIL-FIRED BOILER MUST BE CONNECTED

TO A VENT HAVING SUFFICIENT DRAFT AT ALL TIMES TO

ENSURE SAFE AND PROPER OPERATION OF THE BOILER.

Loading...

Loading...