Local settings

Running times

Instruction manual EBF / EBF ECO page 12 of 19

11/2014

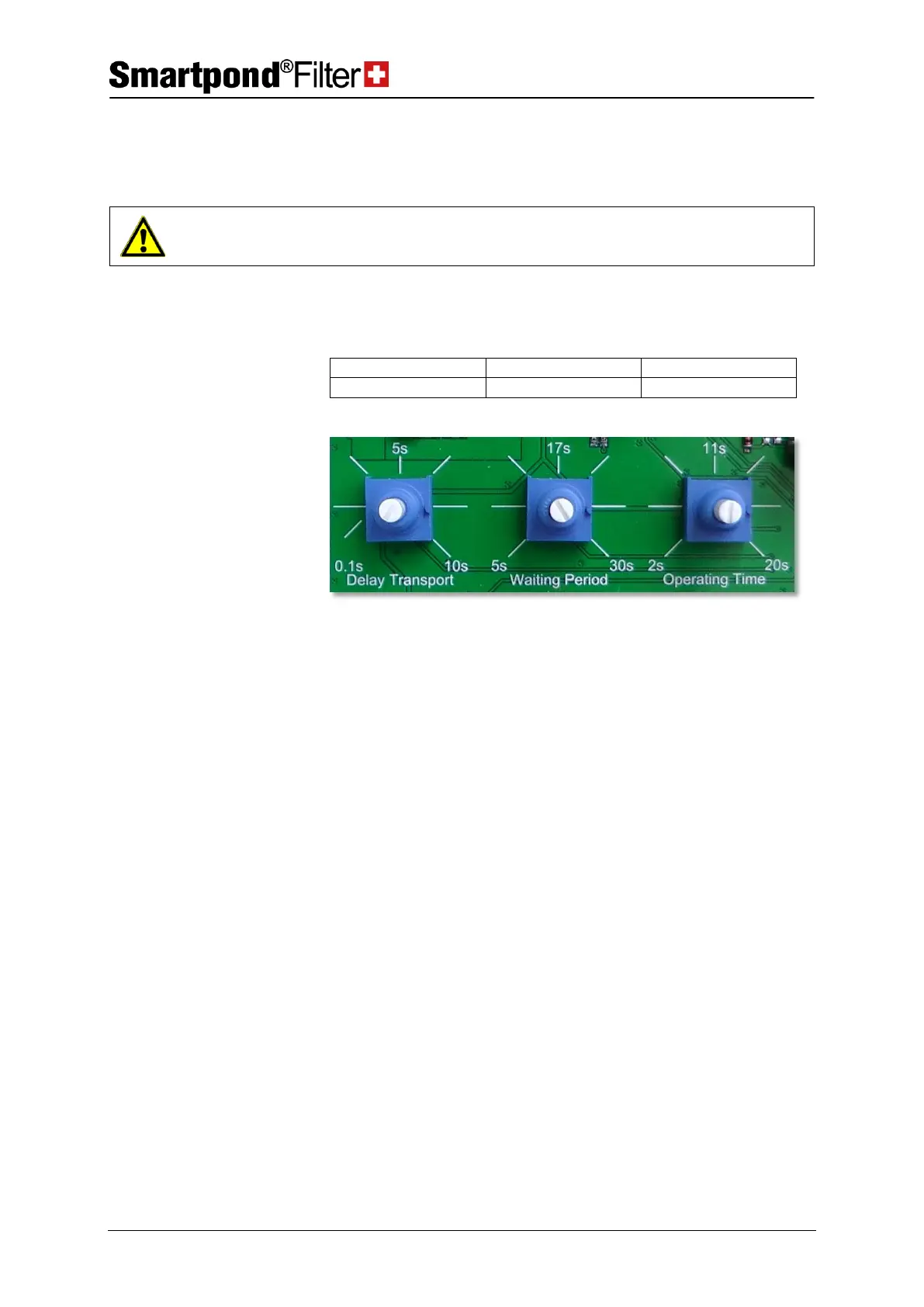

The feed times etc are adjusted in the control unit box using three

potentiometers according to the conditions of the local pond area.

Before the control unit box is opened, the supply cable is disconnected

from the power socket!

On the Smartpond® circuit board, there are three potentiometers with the

following designations:

Functioning of the control unit

Start of the cleaning

cycle

B1 (float gauge)

When the fault gauge sensor B1 is pressed, the cleaning cycle begins. The

spraying pump is triggered for this purpose (Output A2 = power socket for

spraying pump).

After a fixed delay time of 1 sec, the time P1 begins (delay of the pump)

which can be adjusted between from 0.1 to 10 sec.

Default setting ex factory: 0.1 Sec. = minimum; left-hand limit stop

After this time lapses, the conveyor belt starts moving (Lead L2)

Running time of the

conveyor belt

P3

The conveyor belt runs for a specific running time (P3) which can be varied

between 2 and 20 sec.

Default setting ex factory: ca. 11 sec. = Mean (ca. 12:00)

End of the cleaning

cycle

After the P3 time period lapses, the conveyor belt stops to move. But the

spraying pump operates for a fixed programmed time of 1 sec longer so

that no dirt remains on the belt or reaches the clean bio-chamber.

Waiting time till the

next cycle possible

P2

After the spray nozzle stops, the delay time P2 (waiting time) begins, which

can be varied between 5 and 30 sec.

Default setting ex factory: 30 sec. =max; right-hand limit stop

After the waiting period has passed, a new cleaning cycle can begin (if the

float gauge sensor is activated).

Loading...

Loading...