22

Use only the adapters and vent system listed in Tables 12 and 13.

DO NOT mix vent systems of different types or manufacturers.

Failure to comply could result in severe personal injury, death, or

substantial property damage.

Installations must comply with applicable national, state, and

local codes.

Installation of a polypropylene vent system should adhere to the

vent manufacturer’s installation instructions supplied with the

vent system.

All terminations must comply with listed options in this manual

and be a single-wall vent offering.

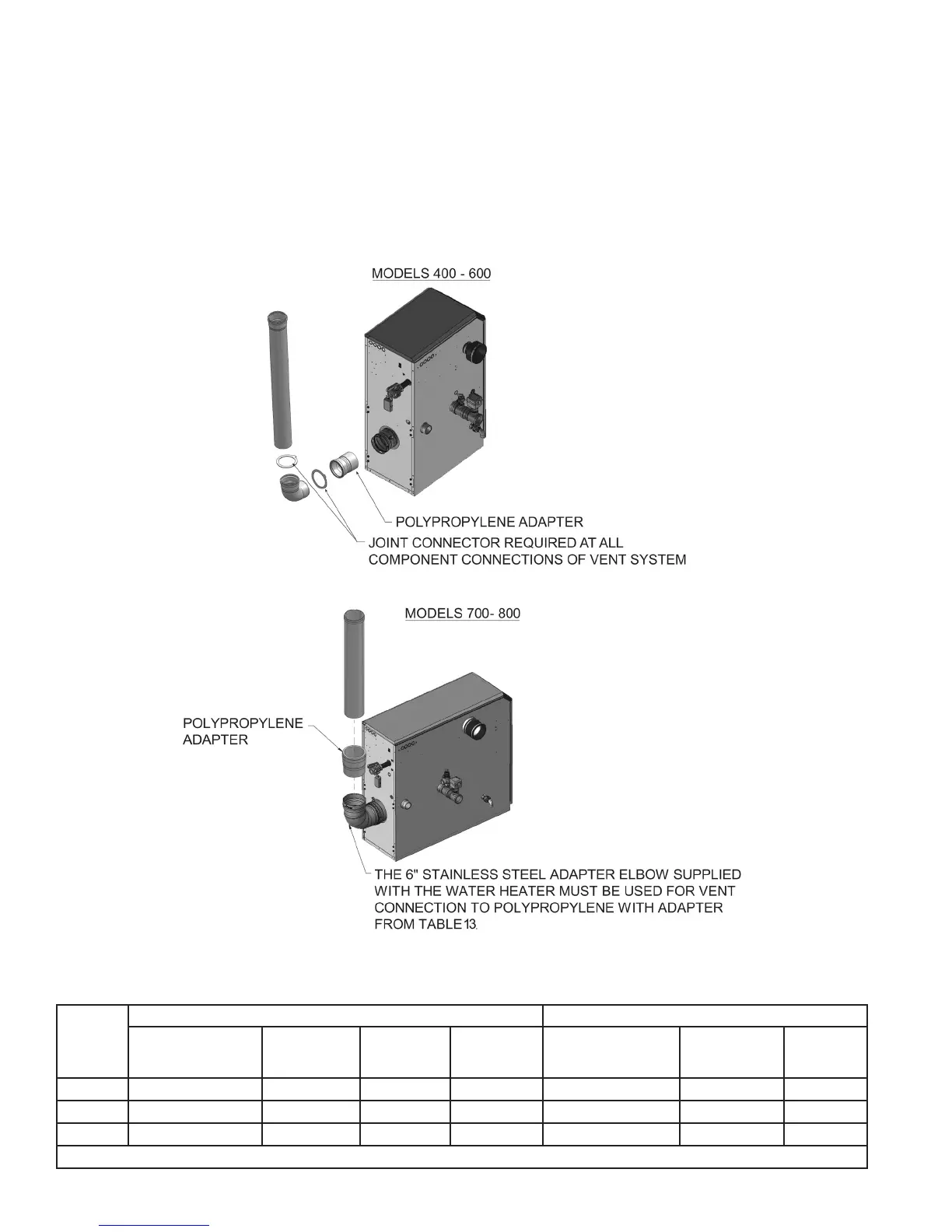

The installer must use a specic vent starter adapter at the

ue collar connection. This adapter is supplied by the vent

manufacturer to adapt to its vent system. See Table 13 for

approved vent adapters. Do not use CPVC starter piece.

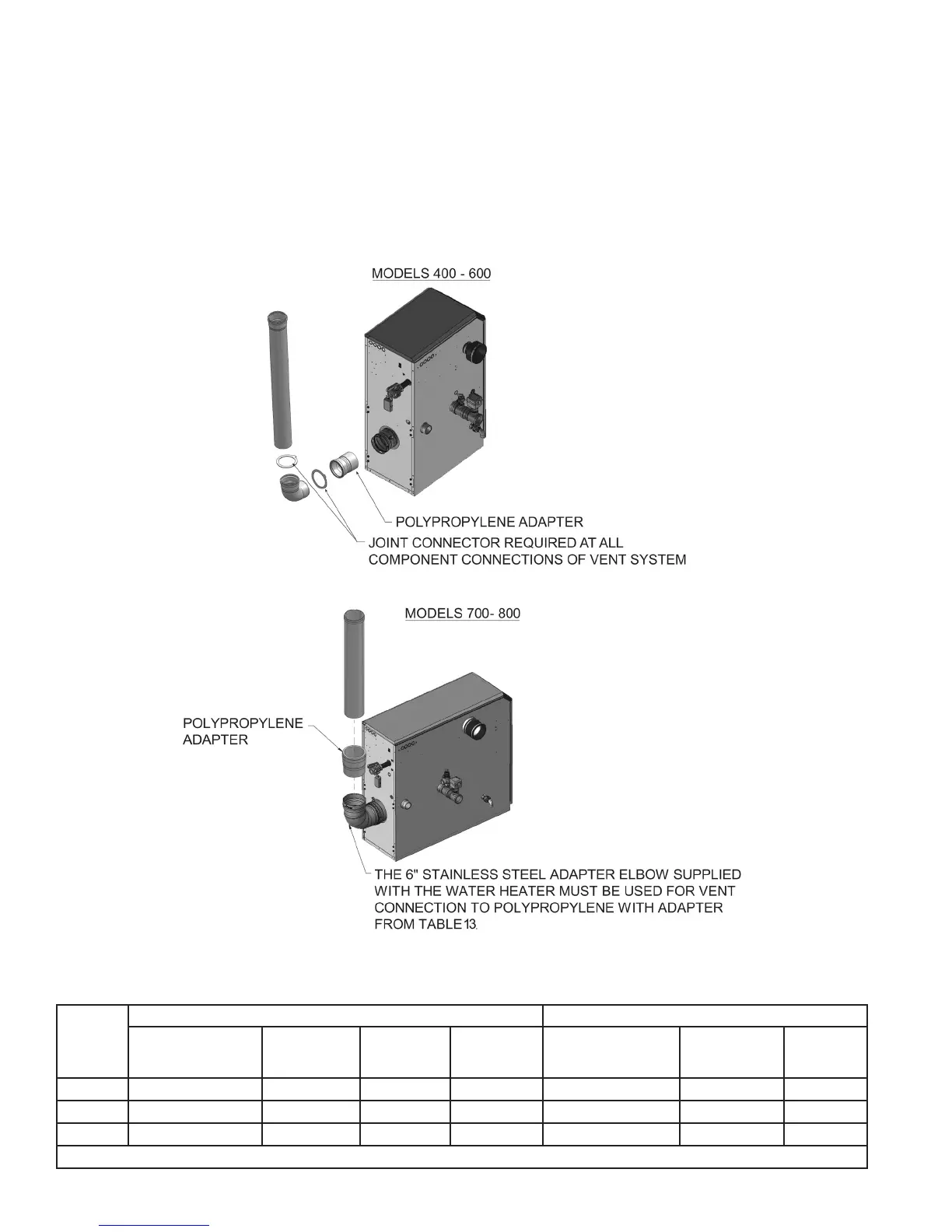

All vent connections MUST be secured by the vent manufacturer's

joint connector (Figure 20).

Insulation should not be used on polypropylene venting

materials. The use of insulation will cause increased vent wall

temperatures, which could result in vent pipe failure.

Table 13. Approved PolypropyleneTerminations

MODEL

CENTROTHERM INNOFLUE SW DURAVENT POLYPRO

POLYPROPYLENE

ADAPTER

JOINT

CONNECTOR

SIDEWALL

RETAINING

BRACKET*

SIDEWALL

ADAPTER*

POLYPROPYLENE

ADAPTER

JOINT

CONNECTOR

SIDEWALL

KIT*

150 - 200 ISAAL0303 IANS03 IATP0303 ISTAGL0303 3PPS-AD 3PPS-LB 3PPS-HLK

400 - 600 ISAAL0404 IANS04 IATP0404 ISTAGL0404 4PPS-AD 4PPS-LB 4PPS-HLK

700 - 800 ISAAL0606 Not Required IATP0606 ISTAGL0606 FSA-6PVCM-6PPS Not Required 6PPK-HLK

* These parts are only needed if the sidewall termination assembly is used (see Figure 31 on Page 27).

Figure 20. Near Water Heater Polypropylene Venting

Loading...

Loading...