44

8. Ensure inlet pressure is within specied range. Minimum and

maximum gas supply pressures are specied in this section

of the manual.

9. If gas supply pressure is within normal range and no

adjustments are needed, proceed on to Step 11.

10. If the gas pressure is out of range, contact the gas utility, gas

supplier, qualied installer or service agency to determine

the necessary steps to provide proper gas pressure to the

control.

11. Turn the power switch to the “OFF” position.

12. Shut off the gas supply at the manual gas valve in the gas

piping to the appliance.

13. Remove the manometer from the pressure tap on top of the

gas valve. On Models 150 - 500 re-tighten the set screw

inside the pressure tap. On Models 600 - 800 remove the

1/8" (3 mm) eld supplied tting and reinstall the pipe plug

removed in Step 3.

When re-tightening the set screw, be sure to tighten securely to

prevent gas leaks. Do not check for gas leaks with an open ame

-- use the bubble test. Failure to use the bubble test or check for

gas leaks can cause severe personal injury, death, or substantial

property damage.

14. Turn on the gas supply at the manual gas valve.

15. Turn the power switch to the “ON” position.

16. Adjust the temperature Setpoint on the control panel of the

UIM to the desired water temperature so the appliance will

call for heat.

17. Check burner performance by cycling the system while you

observe burner response. The burner should ignite promptly.

Flame pattern should be stable. Turn system off and allow

burner to cool, then cycle burner again to ensure proper

ignition and ame characteristics.

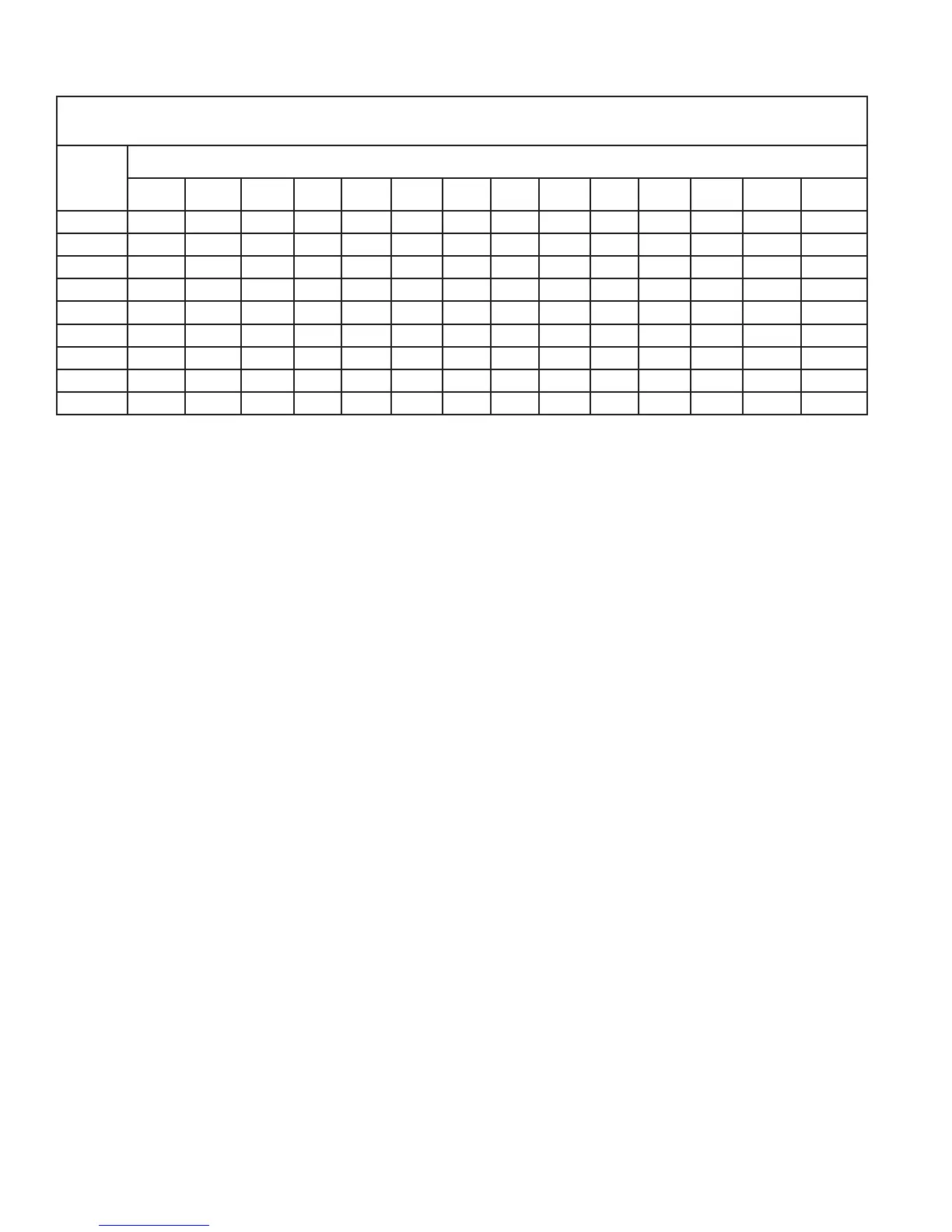

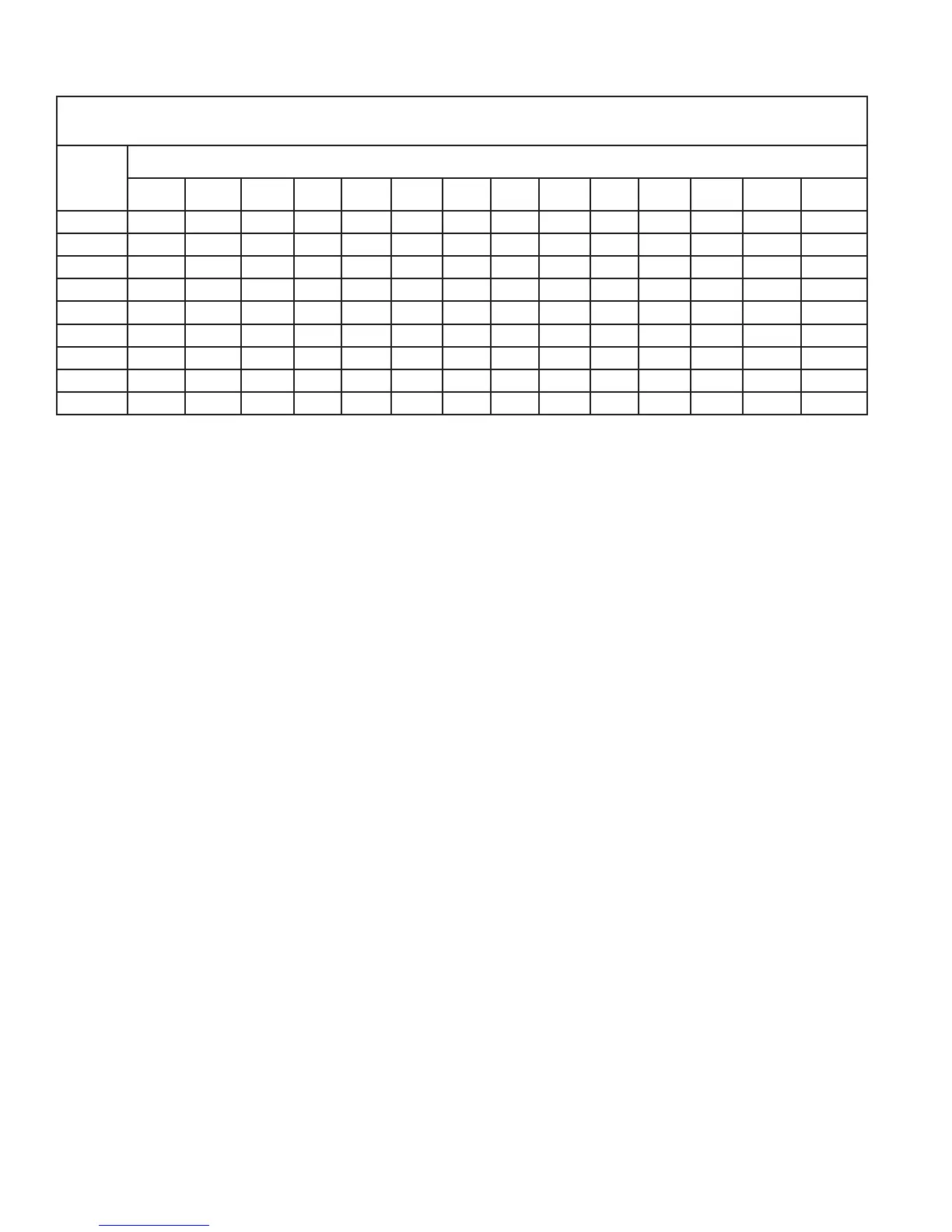

Table 23. Natural Gas Pipe Size Chart

CAPACITY OF SCHEDULE 40 METALLIC PIPE IN CUBIC FEET OF NATURAL GAS PER HOUR

(BASED ON .60 SPECIFIC GRAVITY, 0.30" W.C. PRESSURE DROP)

Pipe

Size

(Inches)

Length of Pipe in Straight Feet

10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/2 131 90 72 62 55 N/A N/A N/A N/A N/A N/A N/A N/A N/A

3/4 273 188 151 129 114 104 95 89 83 79 70 63 58 N/A

1 514 353 284 243 215 195 179 167 157 148 131 119 109 102

1 1/4 1,060 726 583 499 442 400 368 343 322 304 269 244 224 209

1 1/2 1,580 1,090 873 747 662 600 552 514 482 455 403 366 336 313

2 3,050 2,090 1,680 1,440 1,280 1,160 1,060 989 928 877 777 704 648 602

2 1/2 4,860 3,340 2,680 2,290 2,030 1,840 1,690 1,580 1,480 1,400 1,240 1,120 1,030 960

3 8,580 5,900 4,740 4,050 3,590 3,260 3,000 2,790 2,610 2,470 2,190 1,980 1,820 1,700

4 17,500 12,000 9,660 8,270 7,330 6,640 6,110 5,680 5,330 5,040 4,460 4,050 3,720 3,460

XP water heaters are typically shipped ready to re on natural gas. Check the water heater rating plate to determine which fuel the

water heater is set for. If set to natural gas, it may be converted to Propane (LP) by installing an orice or by making a gas valve

adjustment (see pages 15 and 16). In order to operate on Propane (LP) gas, an orice MUST BE installed or a gas valve adjustment

MUST BE made. Failure to comply could result in severe personal injury, death, or substantial property damage.

CHECK INLET GAS SUPPLY

CSA or UL listed exible gas connections are acceptable, but

you must exercise caution to ensure that the line has adequate

capacity to allow your water heater to re at full rate. Consult with

local codes for proper installation or service procedures.

DO NOT adjust or attempt to measure gas valve outlet pressure.

The gas valve is factory-set for the correct outlet pressure. This

setting is suitable for natural gas and propane, requiring no eld

adjustment. Attempting to alter or measure the gas valve outlet

pressure could result in damage to the valve, causing potential

severe personal injury, death, or substantial property damage.

The gas piping must be sized for the proper ow and length of

pipe, to avoid excessive pressure drop. Both the gas meter and

the gas regulator must be properly sized for the total gas load.

If you experience a pressure drop greater than 1 inch w.c., the

meter, regulator, or gas line is undersized or in need of service.

Perform the steps below when checking inlet gas supply:

1. Turn the main power switch to the “OFF” position.

2. Shut off gas supply at the manual gas valve in the gas piping

to the appliance.

3. On Models 150 - 500 loosen the set screw one (1) full turn

from inside the pressure tap on top of the gas valve. On

Models 600 - 800 remove the 1/8" (3 mm) pipe plug on the

inlet ange to the valve and install a suitable 1/8" (3 mm)

tting (eld supplied) for the manometer tubing. Place the

tubing of the manometer over the tap once the set screw is

loosened or the 1/8" (3 mm) tting is installed (depending on

model) as shown in Figure’s 66 thru 69 on Page 45.

4. Slowly turn on the gas supply at the eld installed manual

gas valve.

5. Turn the power switch to the “ON” position.

6. Adjust the temperature Setpoint on the control panel of the

Control Module to call for heat.

7. Observe the gas supply pressure as the burner res at 100%

of rated input. Percent of burner input will be displayed on

the control panel.

Loading...

Loading...