7

ASSEMBLING THE UNIT

Position the welding machine so as to allow the free circulation

of air inside and, as much as possible, prevent metal or other

dusts from penetrating.

• Electrical supply: ensure that there is a 208 or 230 volt,

single phase, 30 ampere electrical supply within easy reach

of the unit. The input cable supplied is 9 feet long.

Attach a suitable plug making sure the green yellow wire is

attached to the ground terminal of the wall plug. All wiring

should be performed by a qualied electrician

• The machine must be installed by professional personnel.

• All the connections must be performed in compliance

with applicable standards (IEC/CEI EN 60974-9) and with

accident-prevention laws.

• Make sure the power supply voltage corresponds to the

welding machine rating.

• The protection fuses must be sized according to the details

shown on the technical data plate.

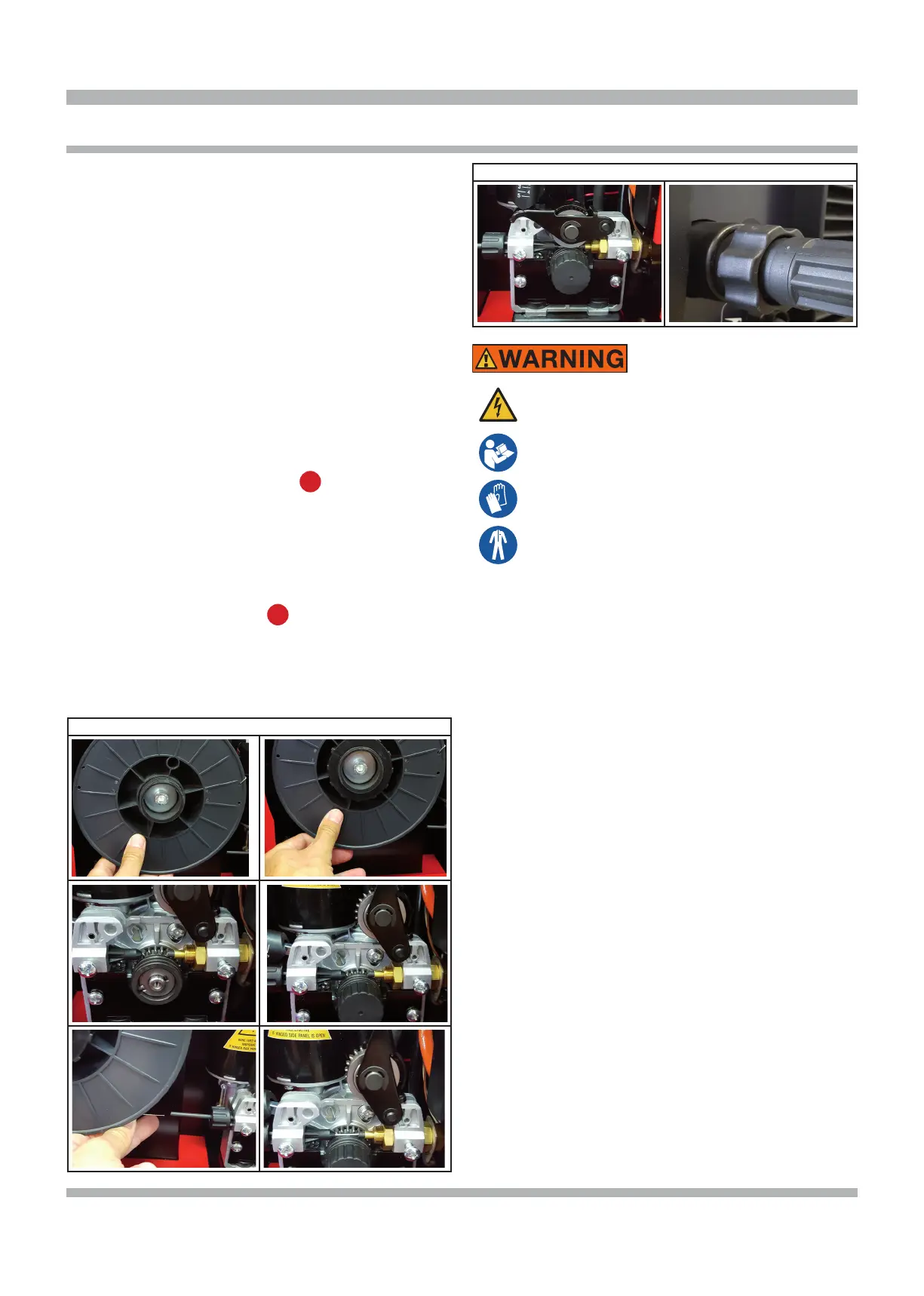

Make sure the ground wire

D

, inside the reel

compartment, is connected to the negative pole

coming out of the dividing wall.

Alongside the two terminals is positioned a plate, which

explains the correct polarity to be used with cored wire

without gaseous protection or a wire with gaseous

protection.

Connect the ground lead clamp

D

to the piece to be welded.

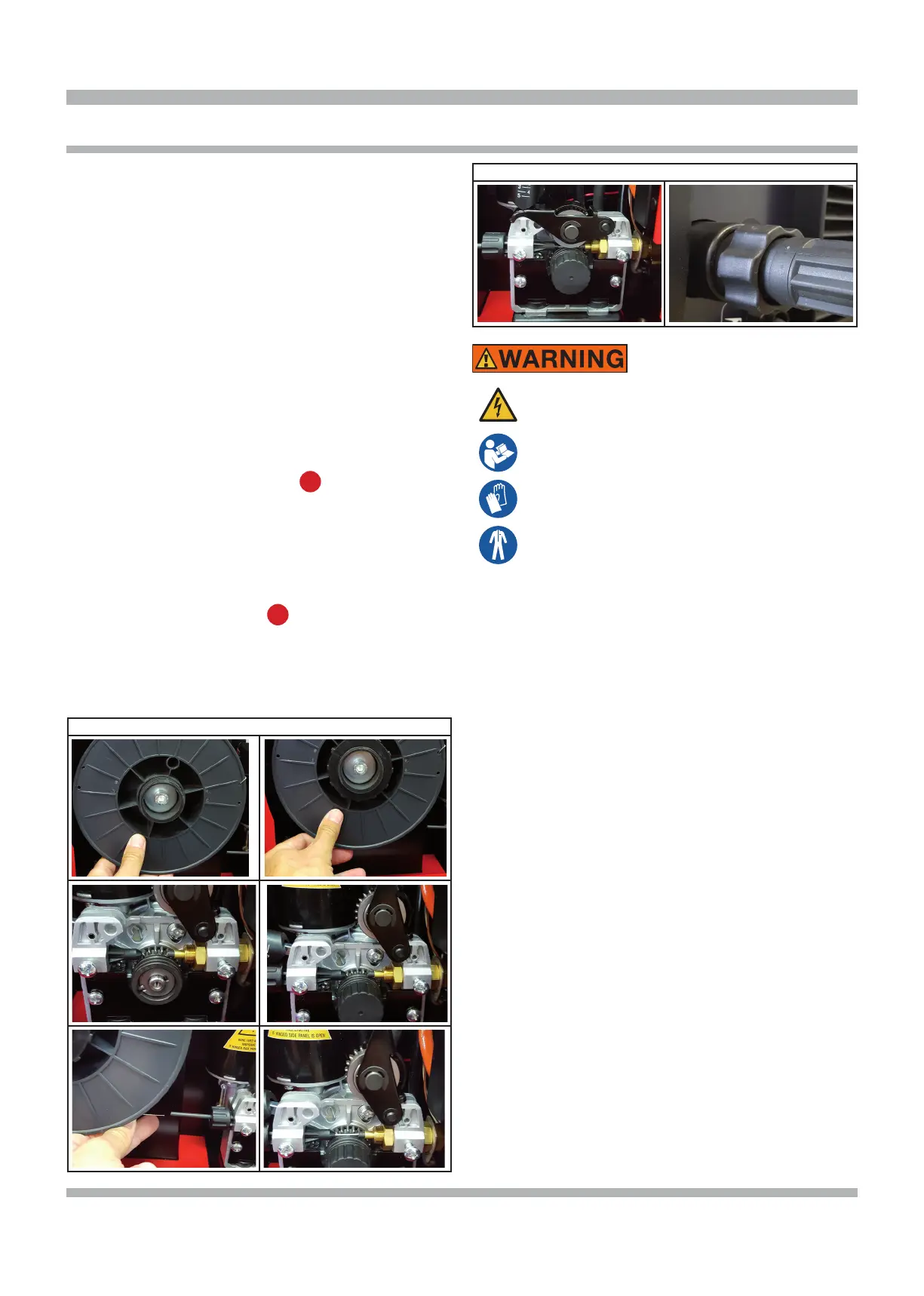

Open the side door. Install the wire reel according to the

instructions provided below.

NOTE: The wire feed motor is inoperative if hinged

side panel is open

REEL FITTING SEQUENCE

fig.1

fig.2

fig.3 fig.4

fig.5

fig.6

REEL FITTING SEQUENCE

fig.7 fig.8

Electrical shock can result when contacting live

electrode or internal components

Electrical shock can result from absence of

grounding lug.

Welding machine must be connected to

power source in accordance with applicable

electrical codes.

Please refer to the troubleshooting tip sec-

tion located at our web site (www.800AB-

CWELD.com) for information on wiring the

230 V plug if needed.

Do not touch electrode or internal compo-

nents without protection.

Disconnect power before servicing.

Do not remove the grounding lug in any elec-

trical plug.

Electrical shock can cause injury.

During wire installation, the welder must be switched

off and unplugged to prevent the motor roller from

movingpresenting a risk for the operator.

• Fit the reel on the support inside the compartment as

shown in g. 1.

• The reel must be tted on the support so the wire

unwinds in an clockwise direction. It is important for

the wire to be stopped on the reel on the visible side,

see g. 2. Block the reel on the support, as shown in

the illustration.

• Make sure the drive roller is correctly positioned

according to the diameter and type of wire used. To

remove the roller, align the at part of the roller-bearing

pin at the bottom, so the key can be tted inside the

retention screw. Loosen the screw, remove the roller, t

the roller back on so the race corresponds to the wire

used, see gures 3 and 4.

• Cut the wire with a well-sharpened tool, keeping it

between your ngers so that it cannot unwind, insert it

inside the plastic pipe exiting from the gear motor and,

with the aid of a nger, also insert it inside the brass

adapter, see gures 5-6-7-8.

Loading...

Loading...