9

ASSEMBLING THE UNIT / START-UP GUIDE cont'd

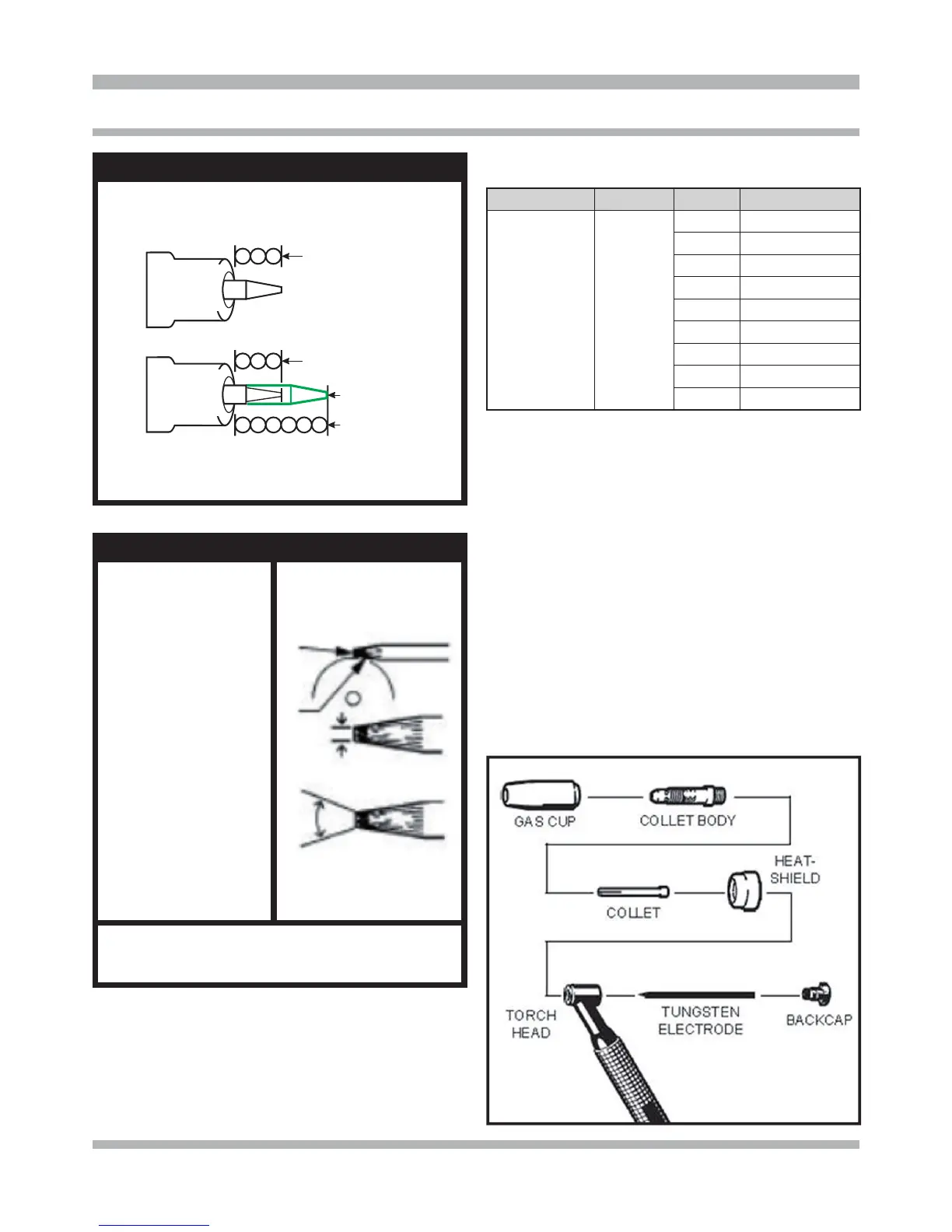

TUNGSTEN EXTENSION

STANDART PARTS

GAS LENS PARTS

(IN DRAFT-FREE AREAS)

General

Purpose

3 x DIA.

General

Purpose

3 x DIA.

MAX:

6 x DIA.

TUNGSTEN GRINDING

Shape by grinding longi-

tudinally (never radially).

Remove the sharp point

to leave a truncated point

with a at spot. Diameter

of at spot determines

amperage capacity. (See

below).

The included angle

determines weld bead

shape and size. General-

ly, as the included angle

increases, penetration in-

creases and bead width

decreases.

Use a medium (60 grit

or ner) aluminium oxide

wheel.

You can also sharpen the tungsten electrode using our

chemical tungsten sharpner part # ckstigsharp.

GUIDE FOR SETTING TIG WELDER

Material Polarity Amps THICKNESS

Steel

Chrome Moly

Stainless Steel

Cast Iron

Brass

Nickel

Copper

DC 25 24 Ga. (.024”)

30 22 Ga. (.030”)

40 20 Ga. (.036”)

50 18 Ga. (.048”)

60 16 Ga. (.060”)

75 14 Ga. (.075”)

105 12 Ga. (.105”)

115 11 Ga. (.115”)

130 1/8” (.125”)

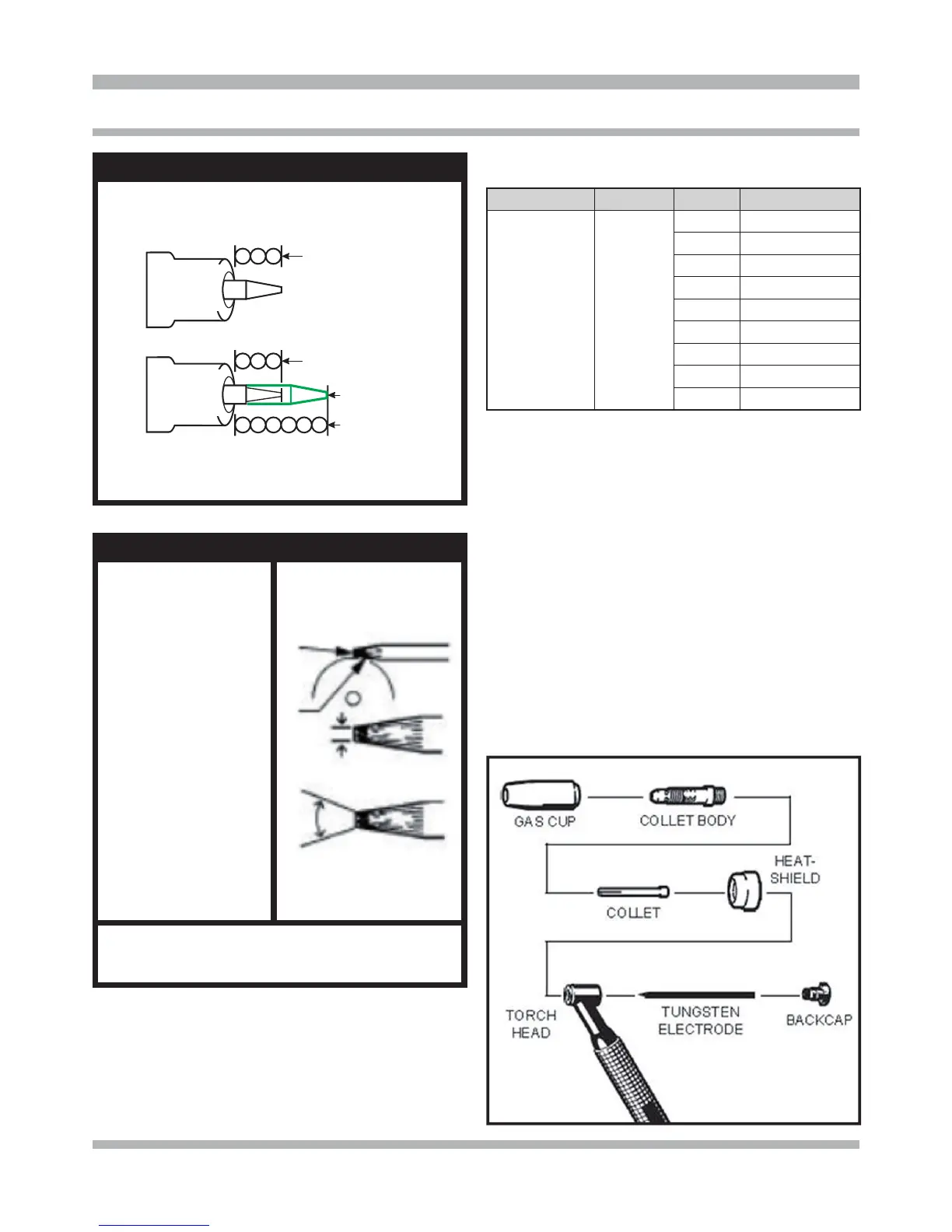

TORCH HEAD ASSEMBLY

1. The electrode to use is the red tipped "2% thorium

tungsten" 1/16" in diameter.

2. Make sure the Te on heat shield is in place.

3. Locate the matching size Collet and Collet body.

4. Drop the Collet, slit-end down, into the Collet body.

5. Screw assembly into the torch head, heat shield side,

and tighten rmly.

6. Install a Gas cap, screw into place seating the cup

against the Te on heat shield.

7. Insert tungsten electrode, prepped end rst, thru the

torch head, Collet and center hole of the Collet body.

8. Allow tungsten electrode to extend past the cup ~ 3

times the electrode diameter.

9. Screw Backcap into torch head and tighten rmly.

Review the exploded view below.

Loading...

Loading...