Chapter 8. Prestart Inspection

Potential service and safety problems may be detected

by inspecting the aerial platform. This chapter includes

information on properly inspecting the aerial platform

and includes a prestart inspection check list at the end

of the chapter to ensure that no areas are overlooked.

The potential for an accident increases when oper-

ating an aerial platform that is damaged ormalfunc-

tioning. Death or serious injury can result from

such accidents.Donot operate the aerial platform if

it is damaged or malfunctioning.

Perform a prestart inspection at the beginning of each

shift, before using the aerial platform on the job. The in-

spection site must have a smooth and level surface.

Operator’s Manual

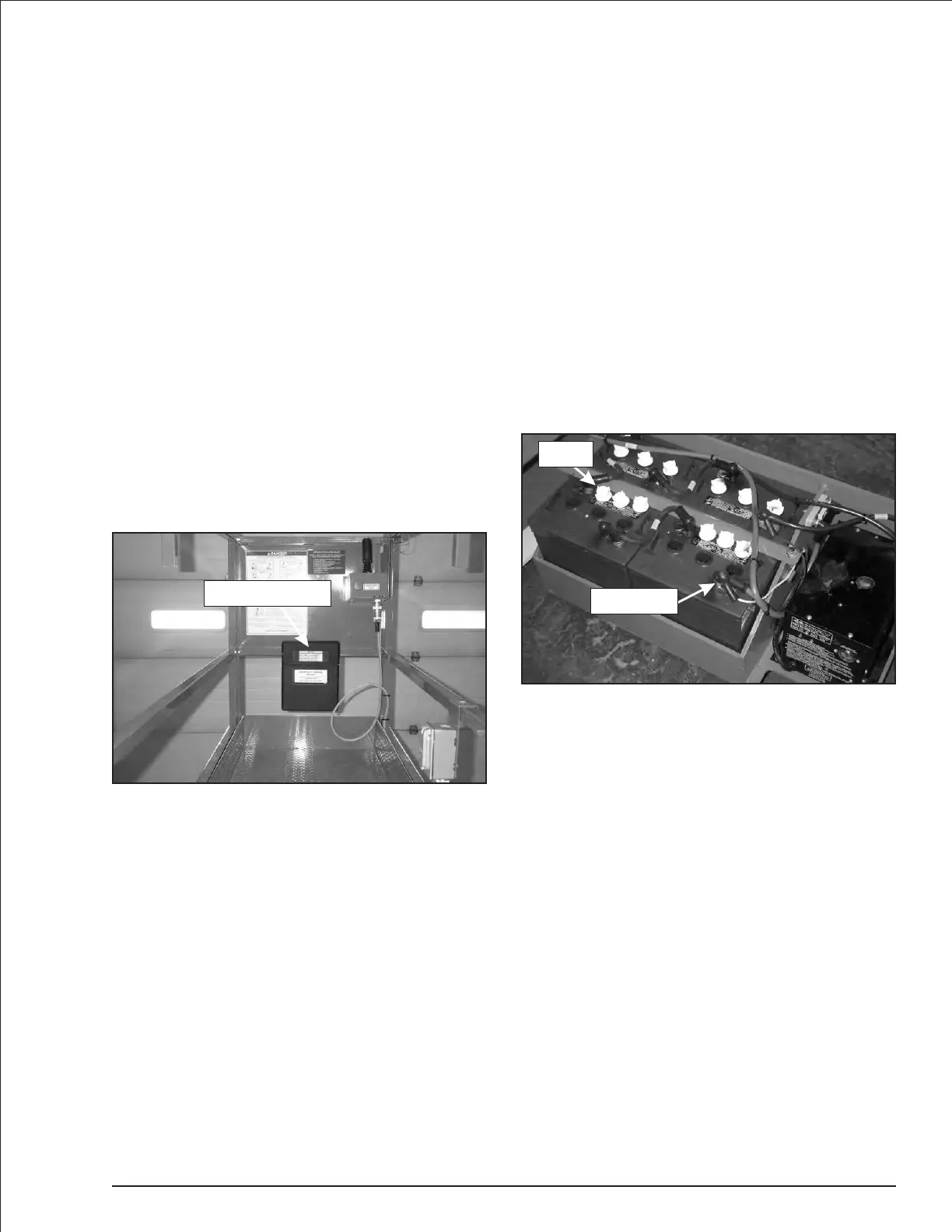

The manual holder is located at the inside the platform

(refer to Figure 8.1) at the front of the machine. Make

certain it is securely fastened in place.

Figure 8.1—Operator’s Manual Holder

Checkto see that the proper Operator’s Manualis in the

holder. The manual should be complete with all pages

intact and in readable condition.

Electrical System

Electrical power is supplied from 4,220 amp hour, 6volt

batteries. These batteries supply 24 volt DC electrical

power to operate the aerial platform drive and control

system.

Batteries give off hydrogen and oxygen that can

combineexplosively.Death or serious injurycanre

-

sult from a chemical explosion. Do not smoke or

permit open flames or sparks when checking the

batteries.

Even with low voltage electrical systems, severe

arcing can occur. Electrical shock or component

damage can result from contact with energized

conductors. Use caution when working with any

electrical device.

The batteries are in the swing-out tray on the left side of

the aerial platform.

Battery Fluid Level

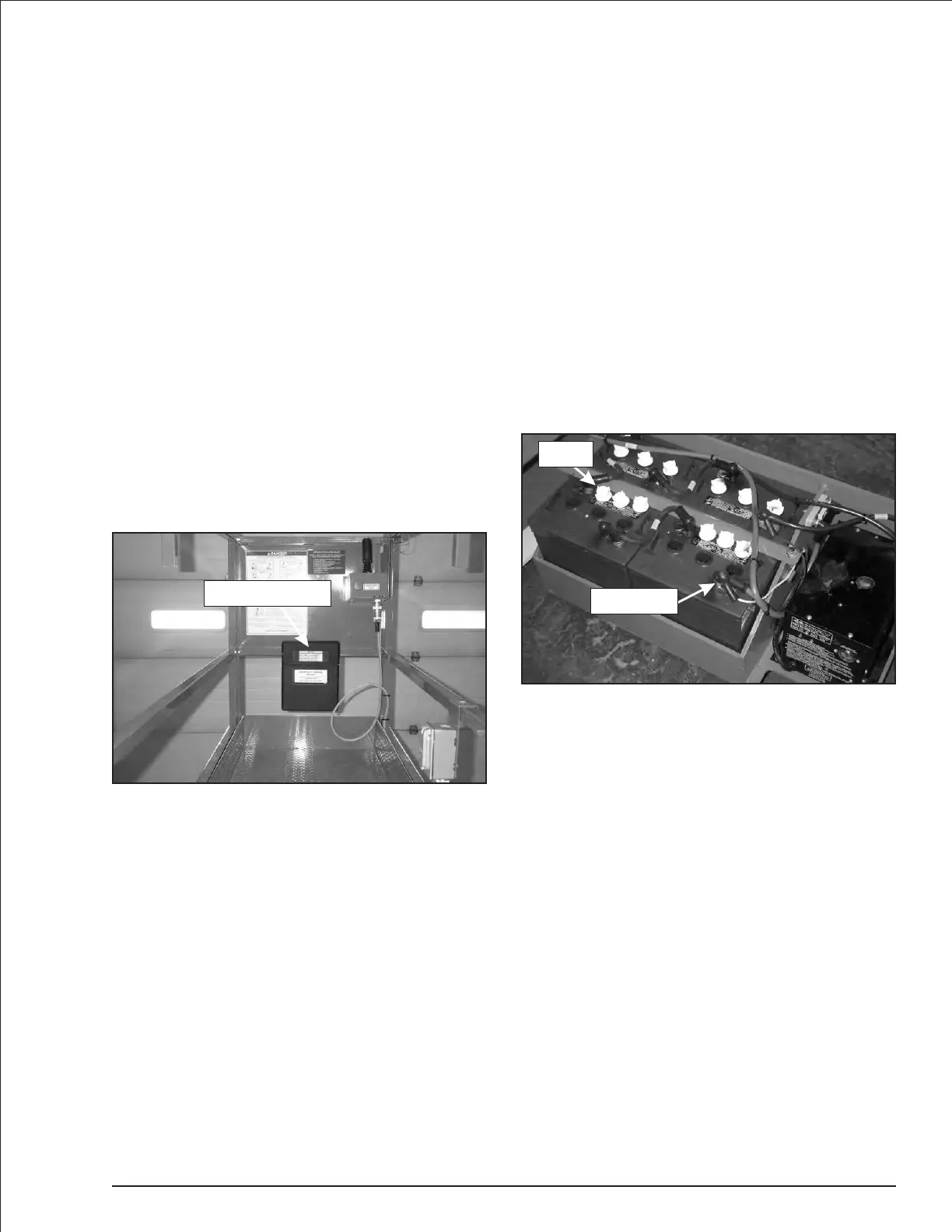

Removethecapsfromeach battery(refer to Figure 8.2).Vi-

sually check the battery fluid level. If the level is not within

1

/4″ (0.6 cm) of the bottom of the filler neck inside each

hole, add distilled water.

Figure 8.2—Batteries

Replace the caps on the batteries. The caps must be in

place and tight during machine operation and battery

charging.

Battery Terminals

Check the top of the batteries, the terminals, and cable

ends(refer to Figure 8.2).They should be clean and free

of corrosion and dirt. Clean the top of the batteries if

necessary. Clean the terminals and cable ends with a

wire brush or terminal cleaningtool.All cable ends must

be securely fastened to the terminals.

Battery Charger

Inspect the battery charger (refer to Figure 8.3) to en-

sure that it is operating properly.

1. Turn the battery disconnect switch off.

2. Plug the charger into a source of power.

S1930 – 0361266 8-1

ADANGER

ACAUTION

ADANGER

Manual Holder

Caps

Terminals

Loading...

Loading...