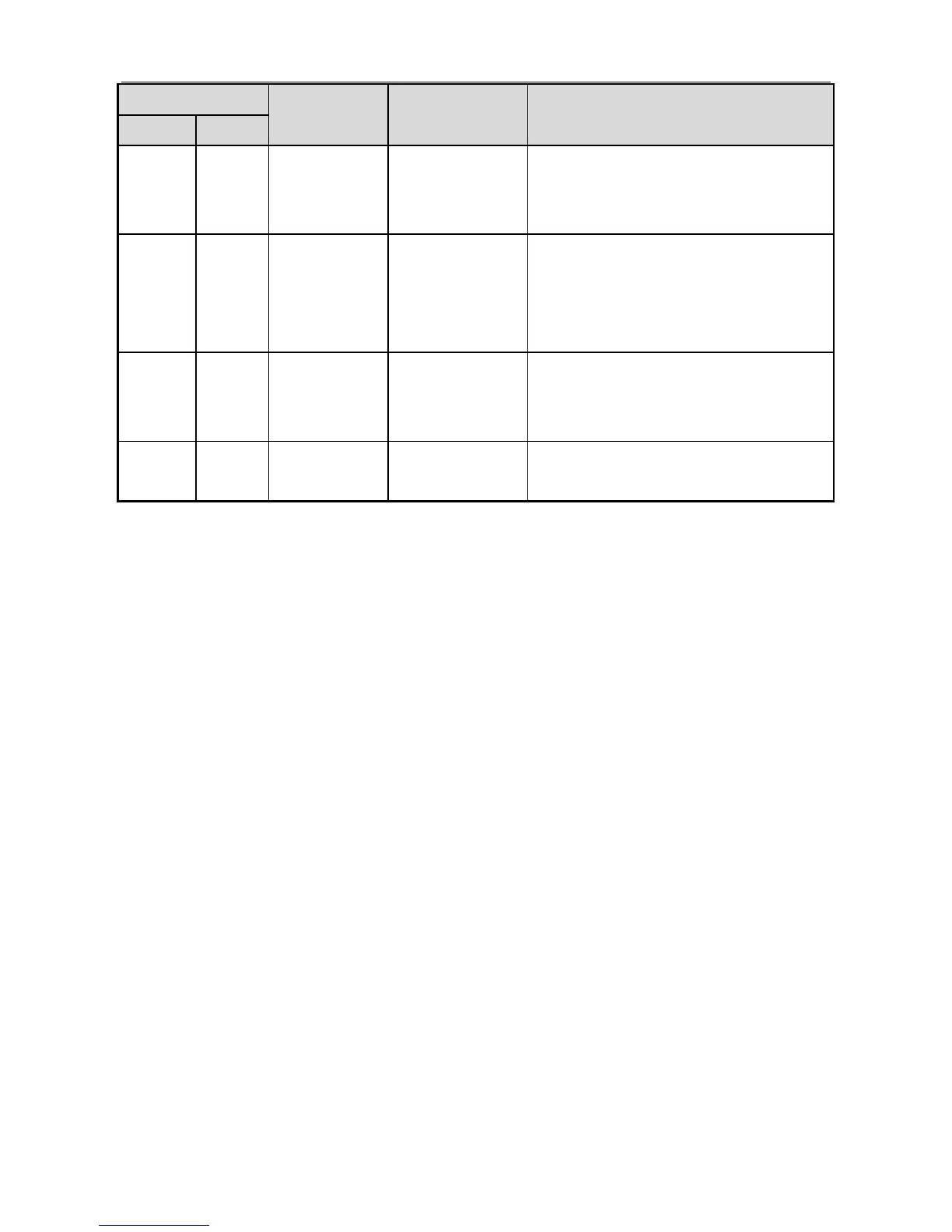

1.Vibration,

temperature rise

2.Noise

3.Wire, terminal

1. Stable vibration, normal temperature of the

shell.

2.No abnormal noise and peculiar smell

3.Fastening screw not loose

√ Motor

1. Vibration,

temperature rise.

2.Noise

1.Steady running and normal temperature

2.No abnormal and uneven noise

√

Input and output

parameter

1.Input voltage

2.Output current

1.Input voltage in the specified range

2.Output current under the rated value.

5.2 Inspection and Replacement of the Damageable Part

Filter Capacitor

Pulsating current of the main circuit will influence on the performance of the

aluminum electrolytic filter capacitor, the impact depends on the environment

temperature and working condition. In normal condition, the controller shall replace

its electrolytic capacitor every 10 years. When the filter capacitor’s electrolyte leaks,

safety valve bursts out or the capacitor main body expands, it shall be replaced

immediately.

5.3 Storage and Warranty

Storage

If the controller is not used temporarily or stored for long time after purchasing,

please pay attention to the following points:

1. Avoid placing the controller in high temperature or humid and vibrating place or

with metal dust, ensure good ventilation.

2. When controller is long time no used, the internal filter capacitor performance will

decline. It is necessary to power on the controller every 2 years to restore the

performance of the filter capacitor, and the controller can be checked at the same

Loading...

Loading...