TECHNICAL SPECIFICATIONS

The machine is designed to be used outdoors. However, it should be protected from rainfall while it’s in use.

PROTECTION

The machine features all necessary protective measures to ensure proper operation. Temperature sensors ensure

that the components are kept within the operating range.

Monitoring of the supply voltage ensures that the machine operates within expected ranges and, in case of excee-

ding them, is disconnected to prevent possible anomalies.

OPERATING CYCLE AND OVERHEATING

The operating cycle is the percentage of 10 minutes during which the unit can weld at the required power without

overheating. If machine becomes overheated, the welding power will stop. The screen will display an alarm showing

which internal module is the one that has been overheated. The fans turn until the internal temperature is below

40°C. The machine will automatically reset when it reaches a safe temperature again. However, it is recommended to

wait at least 5 minutes before starting to work normally again.

To avoid overheating, reduce the adjusted welding power or the length of the welds.

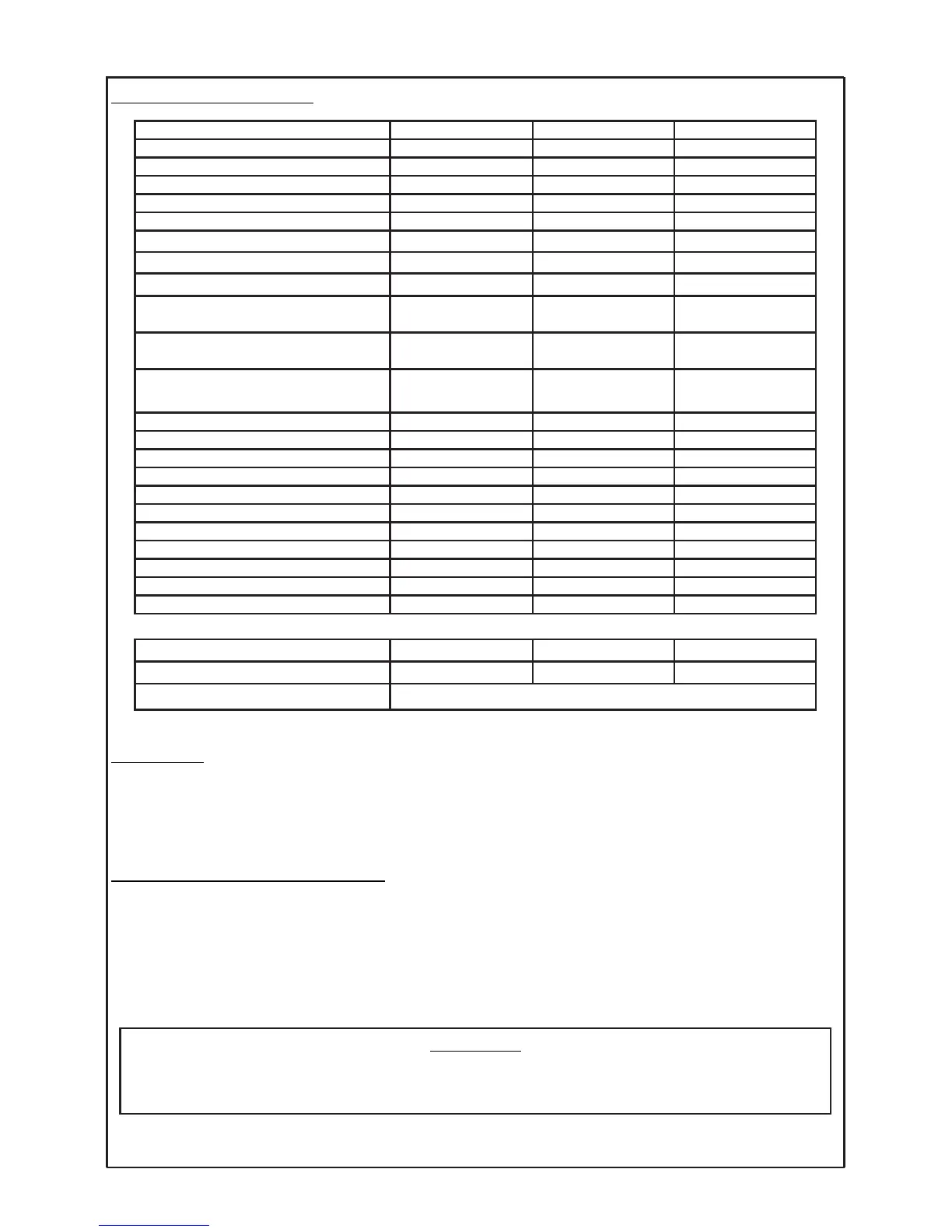

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Input voltage (U1) 230V +/- 15% 400V +/- 15% 400V +/- 15%

M

aximum input current (I1 máx)

3

7A

2

2,2A

2

2,2A

No-load voltage (U0) 68V 64V 64V

Max. absobed power 9KVA 9KVA 9KVA

Fuse 25A 20A 20A

Mig-Mag regulation range 30-200A 30-320A 30-320A

M

MA regulation range

1

0-200A

1

0-250A

1

0-250A

TIG regulation range 10-220A 10-250A 10-250A

Mig-Mag duty cycle

200A 45% (40ºC)

2

00A 68% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

MMA duty cycle

200A 45% (40ºC)

200A 68% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

TIG duty cycle

220A 45% (40ºC)

220A 72% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

Usable wires of Fe 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2

Usable wires of Ss 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2

Usable wires of Al 1,0 - 1,2 1,0 - 1,2 1,0 - 1,2

Maximum feeding speed 11m/min 18m/min 18m/min

Rollers 2R 4R 4R

Power of the motor 30W 65W 65W

Maximum spot time 10s 10s 10s

Temperature protection class H (180ºC) H (180ºC) H (180ºC)

IP protection class IP23S IP23S IP23S

Ventilation FORCED FORCED

FORCED

Weight 19 Kg 58 Kg 56 Kg

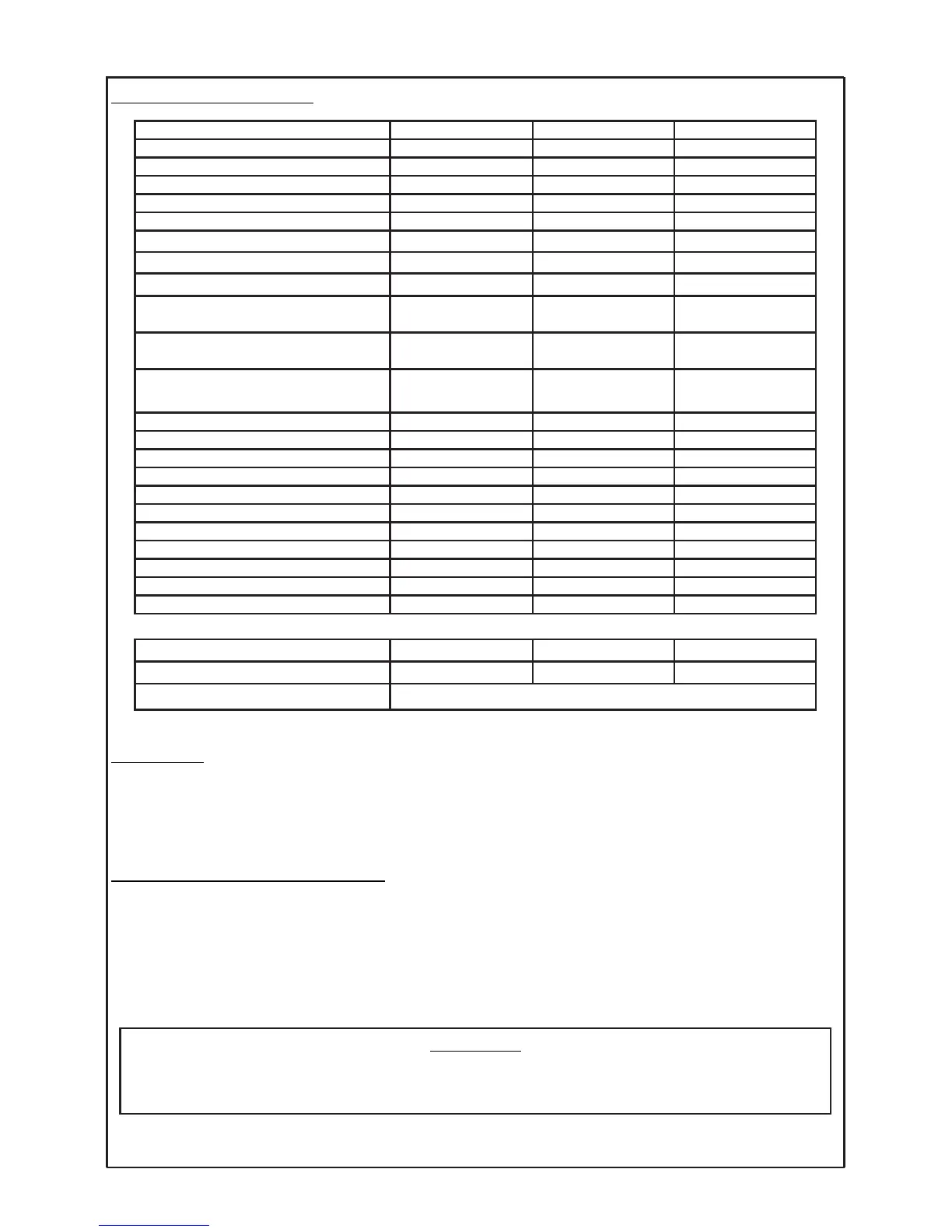

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Dimensions 407x602x285mm 808x935x308 808x935x308

Standards IEC 60974-1 / EC 60974-10

ATTENTION

If the nominal operating cycle of the machine is exceeded and the equipment is forced to work for too

long (without being allowed to cool properly), this could cause significant damage not covered by the

guarantee.

SOLTER SOLDADURA S.L.

AEROPROCESS

4

Loading...

Loading...