AEROFEED 5 WIRE FEEDER

TECHNICAL SPECIFICATIONS

GENERAL DESCRIPTIONS

The wire feed unit is the device that makes wire pass through the contact tube of the gun to be melted in the arc. The

MIG-MAG machines have a system for varying the wire feed speed and a magnetic valve for the passage of gas.

A motor transmits power to the drive rollers to move the wire from the coil to the contact tip of the torch. The rollers in

contact are usually a flat one and a bevelled one. The bevel is V-shaped for hard materials such as steel, U-shaped for

soft materials such as aluminium and grooved for tubular steels. It is essential selecting the right roller for the wire dia-

meter and the kind of material which is going to be used.

CARRYING HANDLE

Whenever you want to manipulate the Aerofeed unit, use the carrying handle. This handle must be used if you want

to hang up the winder. The handle of the unit must be electrically insulated from the metal structure of which will be

suspended.

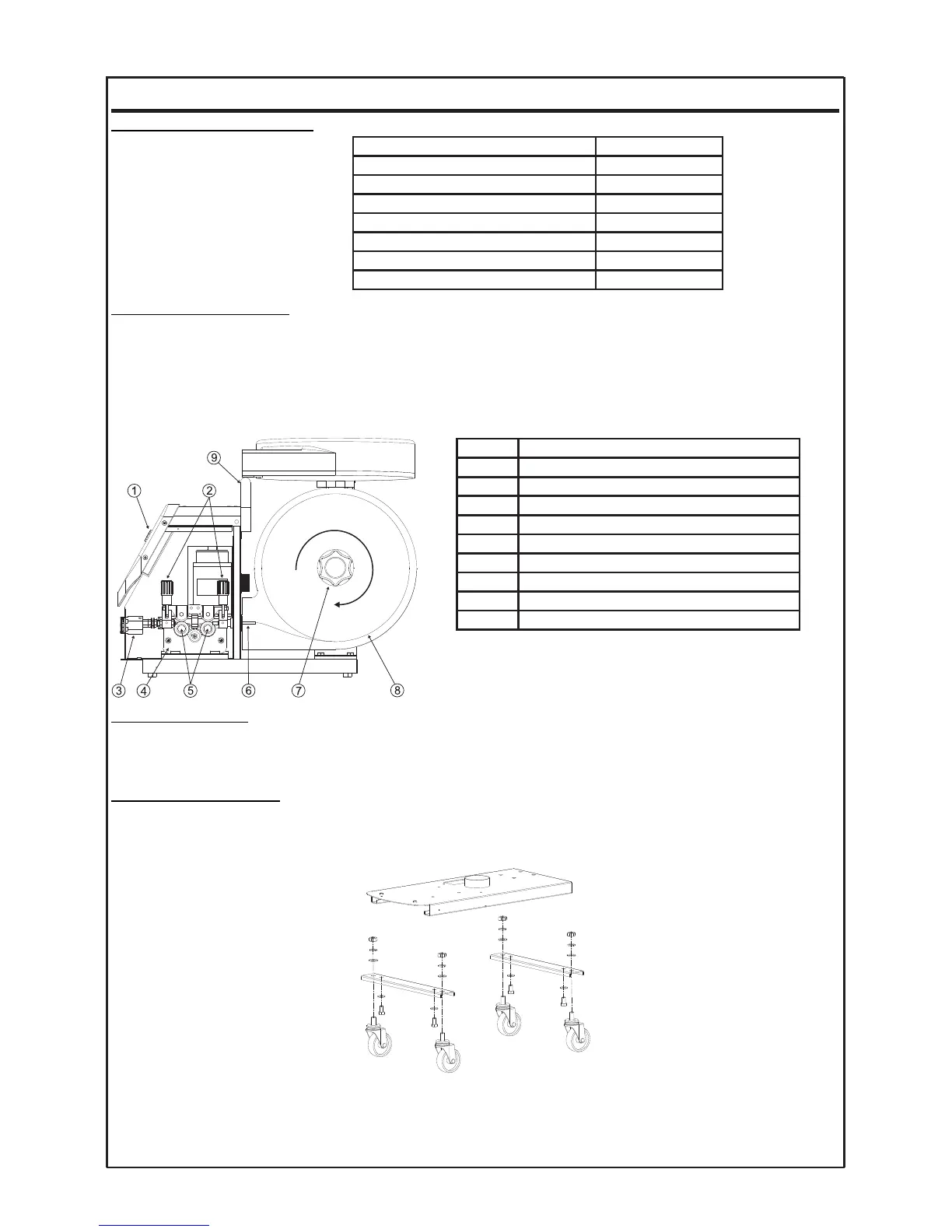

AEROFEED WHEELS KIT

To mount the wheels kit (56206), first remove the 4 nylon feet from the bottom of the unit. Attach the wheels to the 2

brackets and screw these to the base of the winder. Do not reuse the nylon feet to screw the brackets, use the metal

screws provided with the kit.

T

ECHNICAL SPECIFICATIONS

A

EROFEED 5

Input voltage (U1) 24V DC

Maximum output current 500A DC

Suitable diameter wires De 0,6 a 1,2mm

W

ire feed maximum speed

1

8m/min

Duty Cycle 60%

IP Protection class IP23C

Weight 15Kg

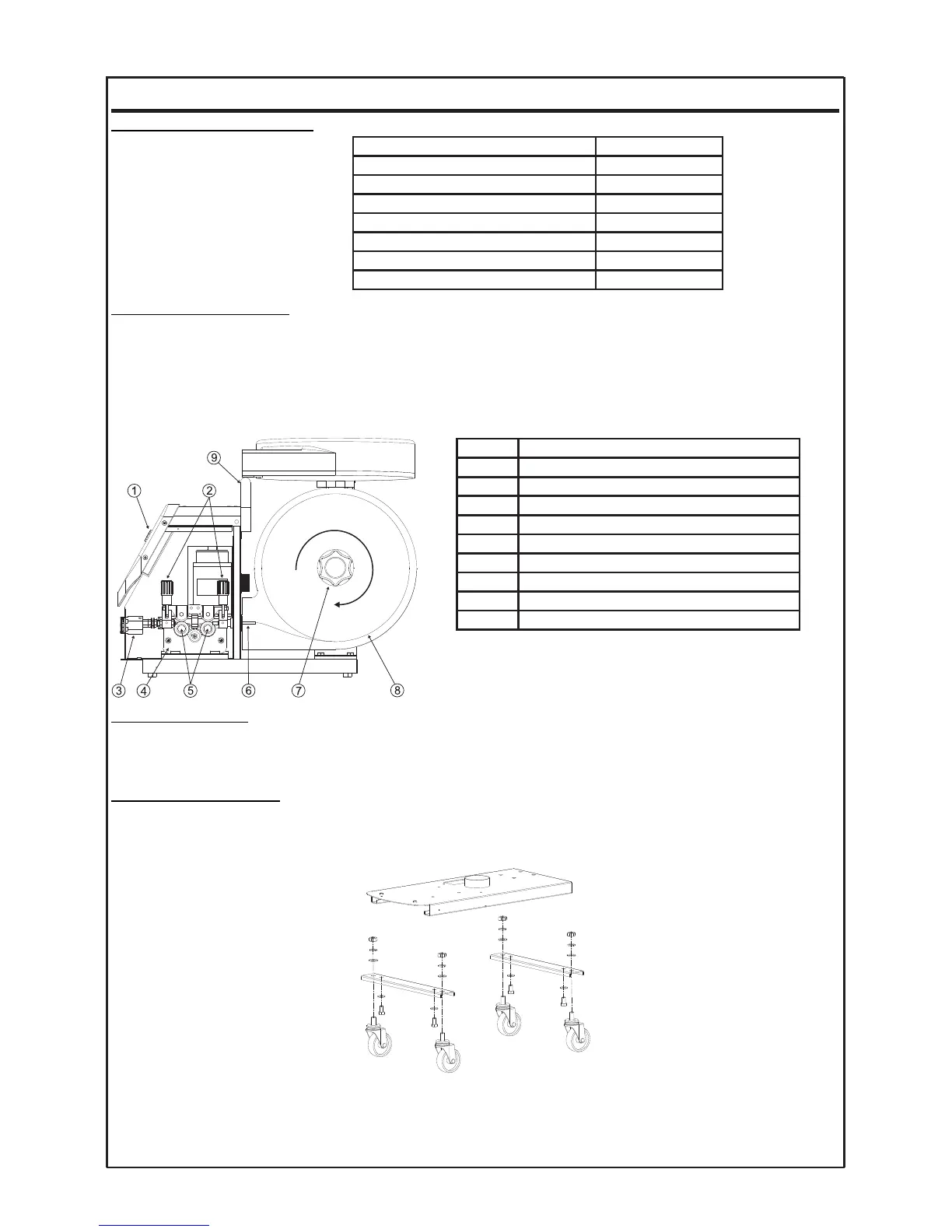

Nº Description

1 Control panel

2 Pressure regulators of the rollers

3 Euroconnector

4 Drive motor

5 Drive rollers

6 Wire guide

7 Wire coil attachment and brake

8 Wire coil

9 Carrying handle

SOLTER SOLDADURA S.L.

AEROPROCESS

18

Loading...

Loading...