MAINTENANCE INSTRUCTIONS

Regular monitoring of the machine is recommended. Before performing any maintenance, unplug the machine from

t

he mains and keep it unplugged during the maintenance operations. Reduce the recommended maintenance inter-

vals in situations of intensive use.

EXPLODED DRAWINGS

Aeropocess 2000 (A1)

Aerofeed 5 (A1)

Aeroprocess 3200 (A2)

Aeroprocess 3220 (A3)

SCHEMATICS

AEROPROCESS 3200 (A4)

AEROPROCESS 3220 (A5)

AEROPROCESS 2000 (A6)

AEROFEED 5 (A7)

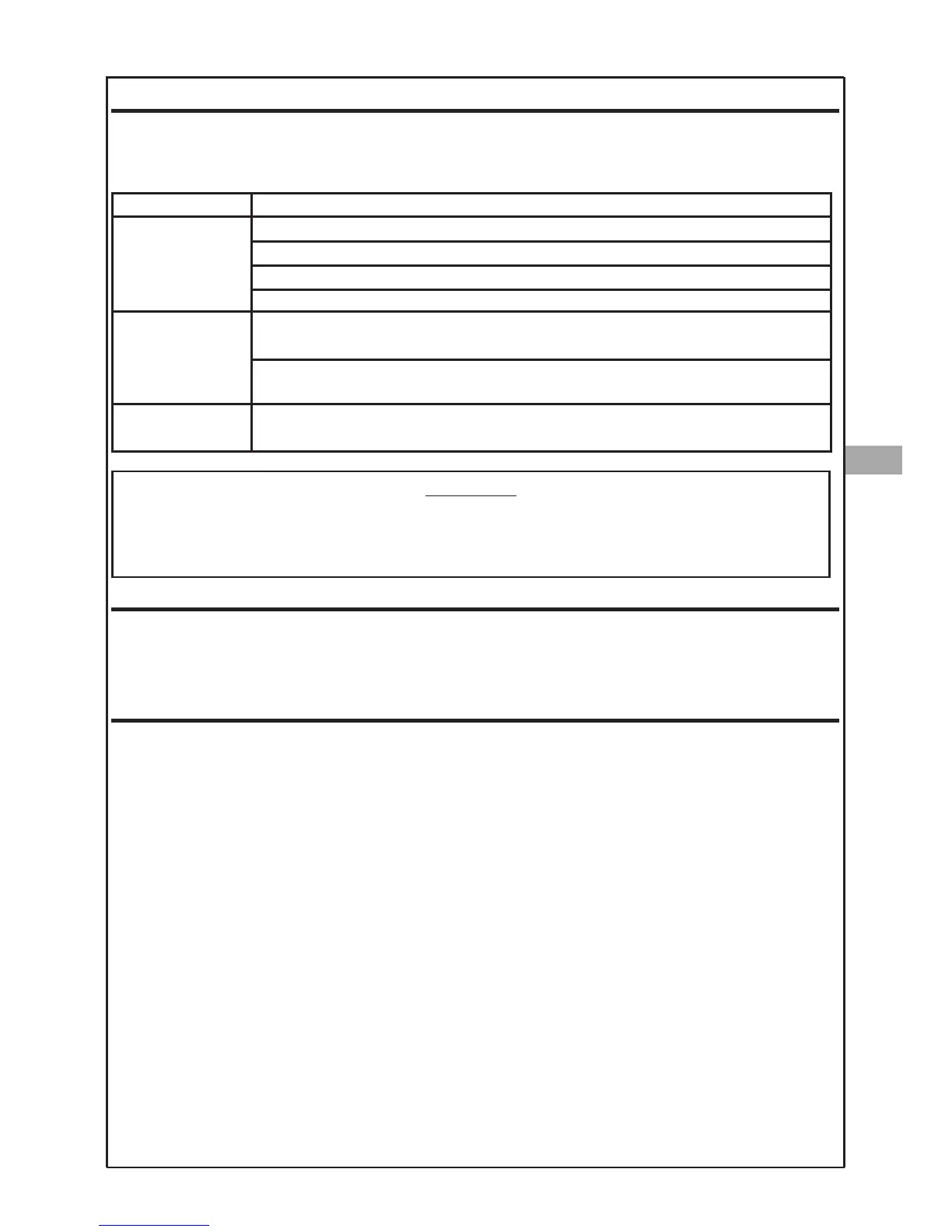

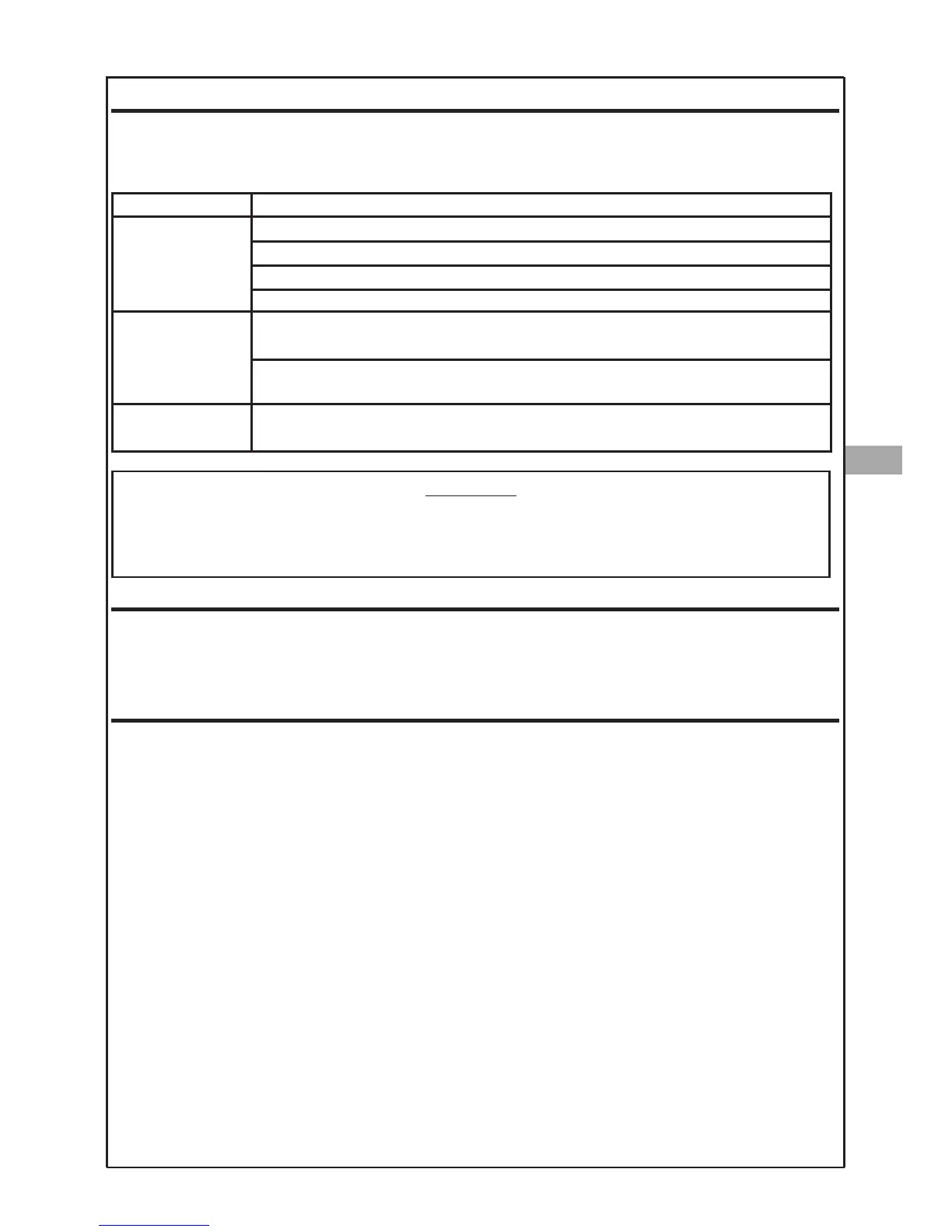

INTERVAL ACTION

Weekly

Check the condition of wiring and external accessories

R

eplace worn components of the torch

C

lean and tighten the electrical connections of the welding circuit

Clean the wire feeder unit with compressed air

Quarterly

Blow the ventilation tunnel with compressed air (dry) from the front intake vents. Don’t re-

move the vents during the operation

Remove all rollers from the drive unit (clean them to remove dust and dirt and then, lubri-

cate them slightly)

Annual Carry out a complete inspection as specified by the standard EN-60974. See your dealer.

ATTENTION

The handling of internal parts of the machine should be performed only by qualified personnel. There is a

risk of electric shock on contact with active parts. You should NOT operate without the covers properly

placed. Before accessing the interior of the machine, unplug it from the mains and wait at least 5 minutes

before carrying out any maintenance operation.

SOLTER SOLDADURA S.L.

AEROPROCESS

21

EN

Loading...

Loading...