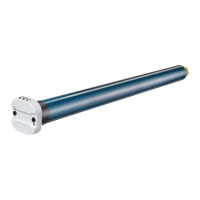

LT50/60 CMO Motor

Installation Instructions

1. TUBE PREPARATION

2. PREPARING THE TUBULAR MOTOR

"SOFT CLIP" "HARD CLIP"

"SOFT CLIP"

"SOFT CLIP" BROWN.

"HARD CLIP"

BLACK.

3. FITTING THE MOTOR INTO THE TUBE

!

!

!

!

!

!

!

Cut the tube to the required length (B), taking into account

the width of the installation (A), the motor end clearance

(C), and the idler end clearance (D). (See Fig. 1)

USE FORMULA TO DETERMINE MEASUREMENTS.

Remove all burrs from the ends of the tube and ensure that

the inside of the tube is clean.

For all round tube sizes up to 3.35" (85 mm) inclusive,

notch the tube on the motor end to the dimensionsA&B.

(See Fig. 2)

For all tubes over 3.35" (85 mm) form a tongue in the motor

end of the tube by making two cuts 1" (25 mm) apart and

.75" (20 mm) deep. (See Fig. 3)

Place the crown wheel over the body of the motor. Slide

the slot in the motor crown over the raised key on the

motor's limit switch unit. (See Fig. 4)

A crown is not necessary on

2.0" Tube when used with LT50, and

2.5" with LT60.

Fit the drive wheel on to the output shaft of the motor.

There are two types of LT drive wheels: Removable or

type, and fixed or type. The

drives are available for round tubes in

2.0", 2.5", and 2.75" diameters. The drive wheel can be

removed by physically pulling it off the motor shaft. For the

ease of identification all drives are

The drives can only be removed from the

shaft by pressing the two clips inward at the same time.

The motor must be out of the tube in order to have access

to the clips. These drives are

For round tubes: Measure the drilling length R according to

the motor type listed in the table below.

(See Fig. 5,

6) Secure the drive wheel to the tube using four 7/32 steel

pop rivets or four 1/4 DIA. screws.

Tube

only

Fit the end plug into the

other side of the tube and secure it with three steel pop

rivets. Use only fasteners with steel grades SAE 5 or higher.

Metric fasteners must be grade 8.8 or higher. (See Fig. 7)

Fit the motor into

the tube ensuring that the notch at the end of the tube

slides over the raised key on the crown wheel.

LT60 CMO

MOTOR

TYPE

R

in./mm

660R2 CMO

680R2 CMO

6100R2 CMO

24.8/630

26.2/665

26.2/665

LT50 CMO

MOTOR

TYPE

R

in./mm

525A2 CMO

530R2 CMO

535A2 CMO

540R2 CMO

550R2 CMO

22.80/579

22.80/579

25.55/649

25.55/649

25.55/649

A

B

C

D

B =A-(C+D)

Fig. 1

Fig. 5

Fig. 4

Fig. 7

R

Raised Key

Fig. 6

Tube Notch

Tube Notch

Tube Diameter

Less than 3.35"

(85mm)

Tube Diameter

Greater than 3.35"

(85mm)

A

B

Fig. 2

Fig. 3

.75"

(20mm)

(25mm)

1"

AB

Length = 25 mm Width=4mmNotch: LT50

LT60 35 mm

8mm

Raised Key

Raised Key

Notch

Loading...

Loading...