A P P L I C A T I O N S – S P O T W E L D I N G

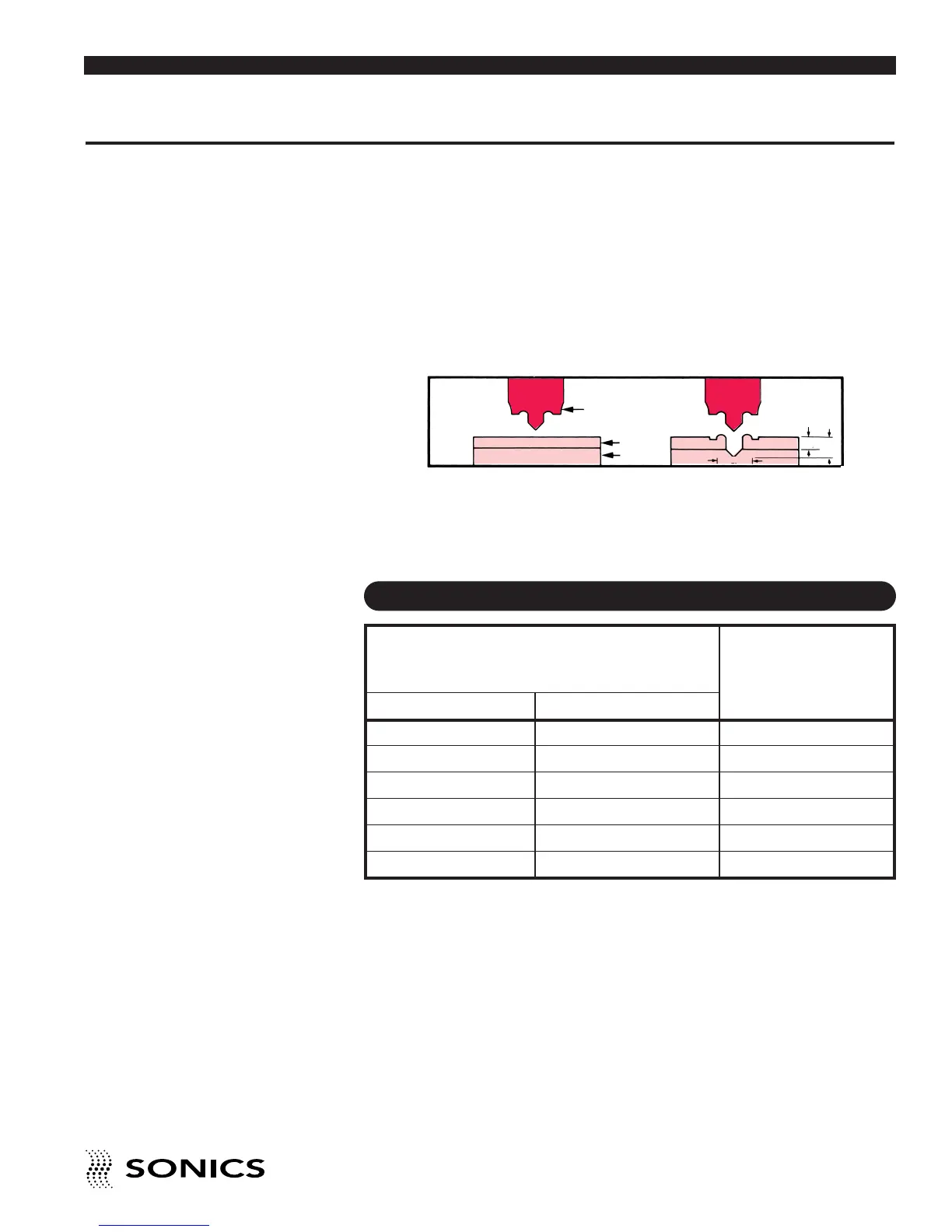

During spot welding, the horn tip penetrates through the top sheet and enters

the bottom sheet to a depth of one half the top sheet thickness. The displaced

molten plastic is shaped by a cavity in the tip to create an annular formation

around the weld. Simultaneously, the molten plastic displaced from the

second sheet flows into the preheated area and forms a permanent molecular

bond. Large thermoplastic parts and applications with hard to reach joining

surfaces can easily be welded together using an ultrasonic spot welder and

standard replaceable tips.

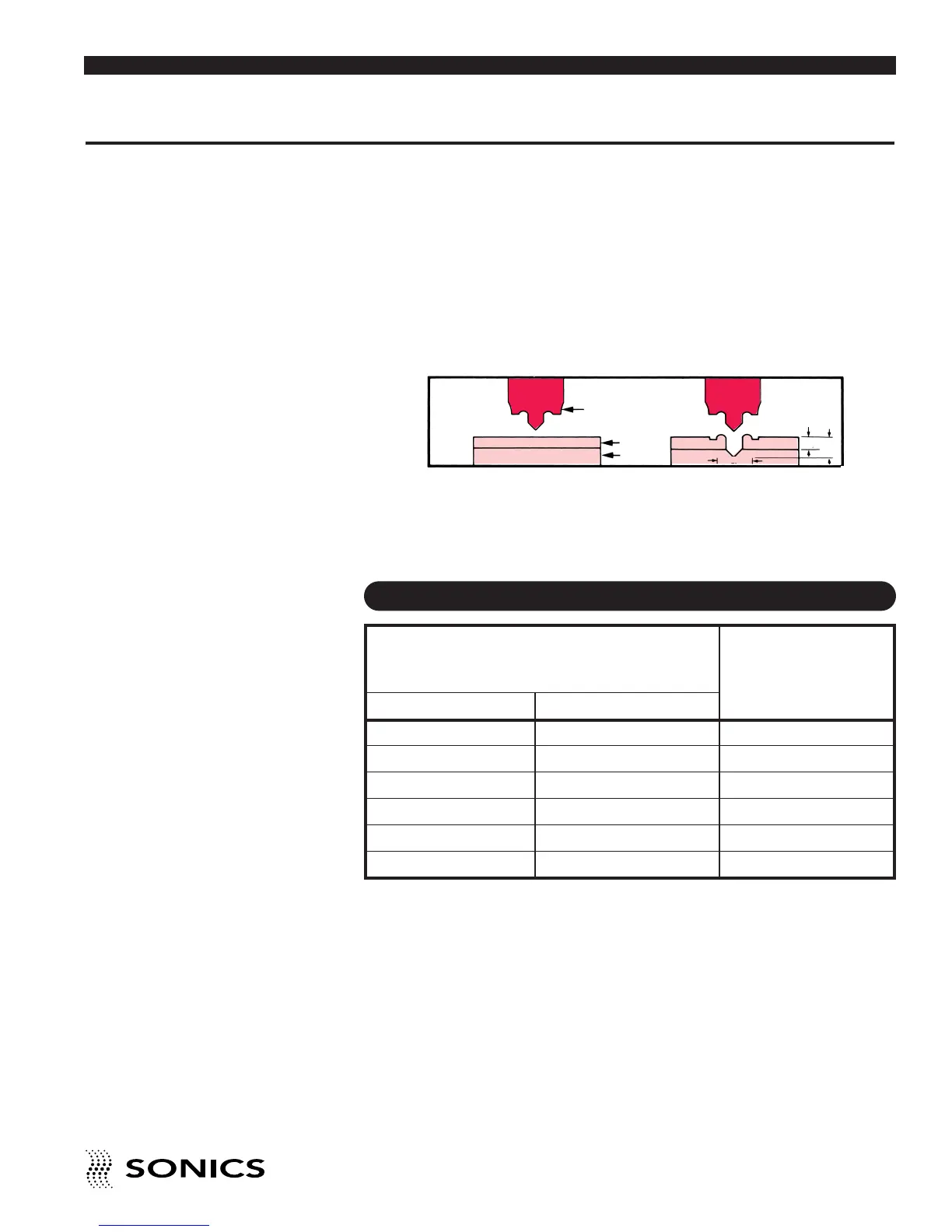

STANDARD THREADED TIPS FOR SPOT WELDING

ORDERING INFORMATION

Specify tip required using code letter.

Example:

Spot weld tip “SA” indicates a tip used for spot welding – 1/32" thick

material.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

I N S T R U C T I O N M A N U A L • M O D E L H 5 2 0 / H 5 4 0

25

BEFORE

AFTER

PLASTIC

HORN

PLASTIC

3t

t

1.5t

Material Thickness TIP

CODE

inches mm

LETTER

1/32 0.793 SA

3/64 1.190 SB

1/16 1.587 SC

5/64 1.984 SD

3/32 2.381 SE

7/64 2.778 SF

SPOT WELDING

Loading...

Loading...