0739P300-E Installation Supercal 739 EN 17-03-2016 5 Sontex SA, 2605 Sonceboz, Switzerland

Commissioning and checking operation

After installing the Supercal 739 compact energy meter, the temperature sensors and the flow meter must be sealed and brought into service.

The waterproof of the installation must be checked.

Make sure that the measurements indicated by the meter are coherent using the orange button which you will find on the meter. The following values can

be shown on the LCD display: flow, power, hot and cold temperatures. The communication arrows permit display of the controls (inputs) and responses of

the instrument (outputs). All the display parameters will be used to check and adjust the installation. In particular, you must make sure that the

maximum flow rate of the installation does not exceed the maximum flow rate authorised for the meter. To complete the functional analysis, the

commissioning protocol can be saved using the Prog739-749 software via the optical interface.

Installation of the Supercal 739

To install the Supercal 739 single jet, the following steps must be respected:

Flush out the installation pipes carefully in compliance with the DIN/EN standard

specification.

Close the shutoff valves before and behind the meter.

Open the drainage valve to reduce the pressure and discharge the water contained in

the pipe between the two shutoff valves.

Consider the direction of flow circulation. Check the flow direction with the arrow figur-

ing on the flow meter.

Place a gasket on each side of the flow meter. Only use appropriate new gaskets.

Make sure that the gaskets are carefully positioned in relation to the water pipe and

flow meter unions.

Tighten the fixing nuts firmly by hand. Then tighten up to the mechanical end stop us-

ing a mounting tool.

Install the temperature sensor.

Turn the display into the desired position for reading.

Check the waterproof of the meter placed under pressure.

Seal the flow meter and the temperature sensors.

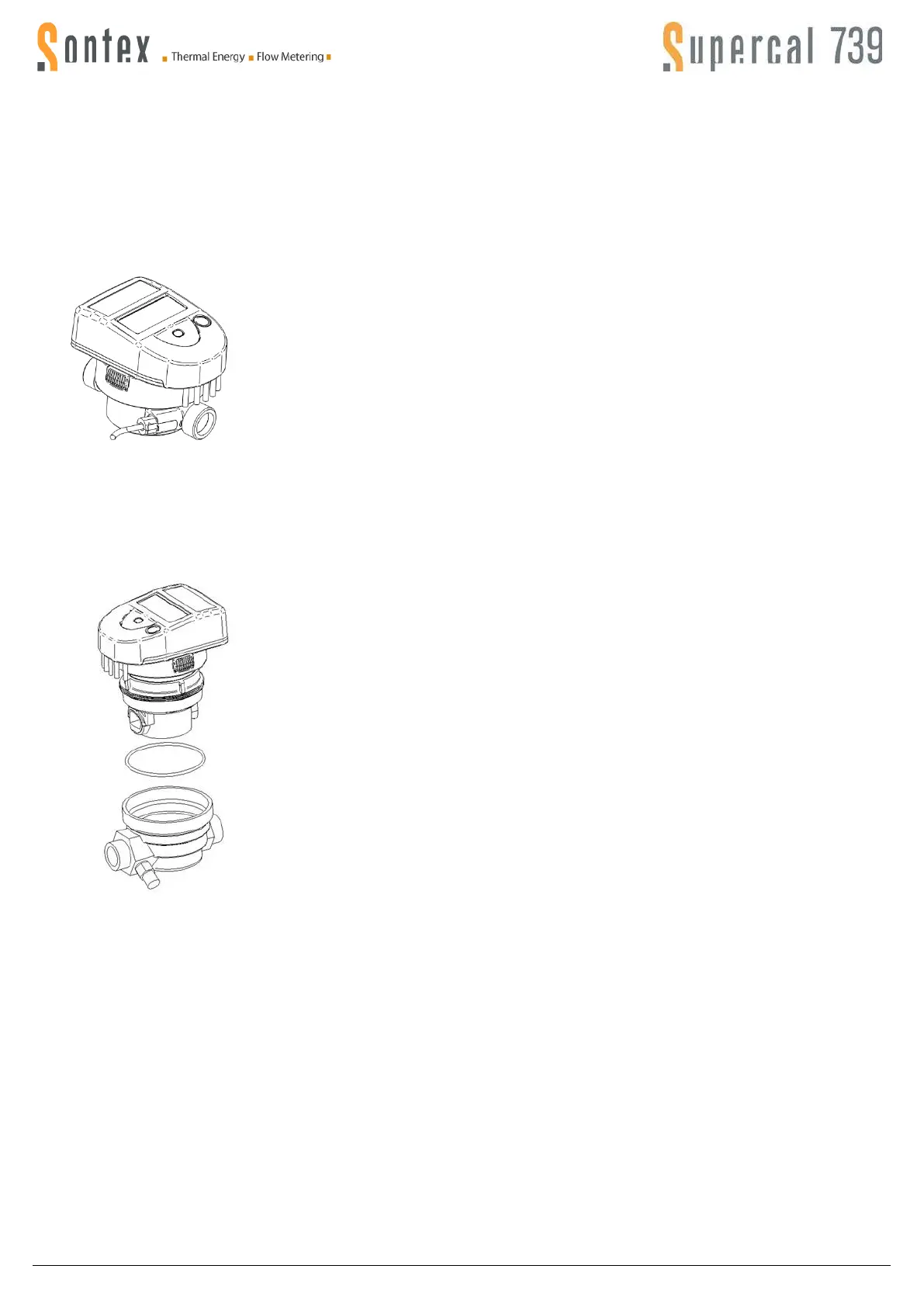

Mounting of the coaxial multi jet meter in the EAS base

Coaxial multi jet meter with M77x1.5 con-

nection

To mount the Supercal 739 coaxial multiple jet with M77x1.5 connection in the EAS base, the

following steps must be respected:

Flush the installation pipes out carefully in compliance with the DIN/EN standard

specification.

Close the shutoff valves before and behind the meter.

Open the drainage valve to reduce the pressure and discharge the water contained in

the pipe between the two shutoff valves.

Consider the direction of flow circulation (EAS base). Check the flow direction with

the arrow figuring on the flow meter.

Remove the blind cover or the old meter from the EAS base using an installation

spanner. Be careful! Water may escape.

Remove the pre-formed gasket then clean the contact surfaces and the thread.

Place the new o-ring in the EAS base. Make sure that the o-ring is correctly posi-

tioned.

Lubricate the external thread (M77x1.5’) of the metering capsule with a fine silicone

coating.

Remove the protection cap from the metering capsule and position the capsule in the

base. Important! Make sure that the blind hole in the metering capsule is correctly po-

sitioned in the base.

Screw the measuring capsule down firmly by hand, then tighten as far as the me-

chanical end stop using a mounting tool.

Install the temperature sensor.

Turn the display into desired position for reading.

Check the waterproof of the meter when it is under pressure.

Seal the measuring capsule and temperature sensors.

Loading...

Loading...