– 6 –

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Before adjusting, clean the following parts with a piece of cot-

ton moistened with alcohol.

record/playback/erase head pinch roller

rubber belt capstan

2. Demagnetize the record/playback/erase head using a head de-

magnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound to the adjusted

parts.

5. Unless specified otherwise, use a specified voltage (3V DC) to

perform the adjustments.

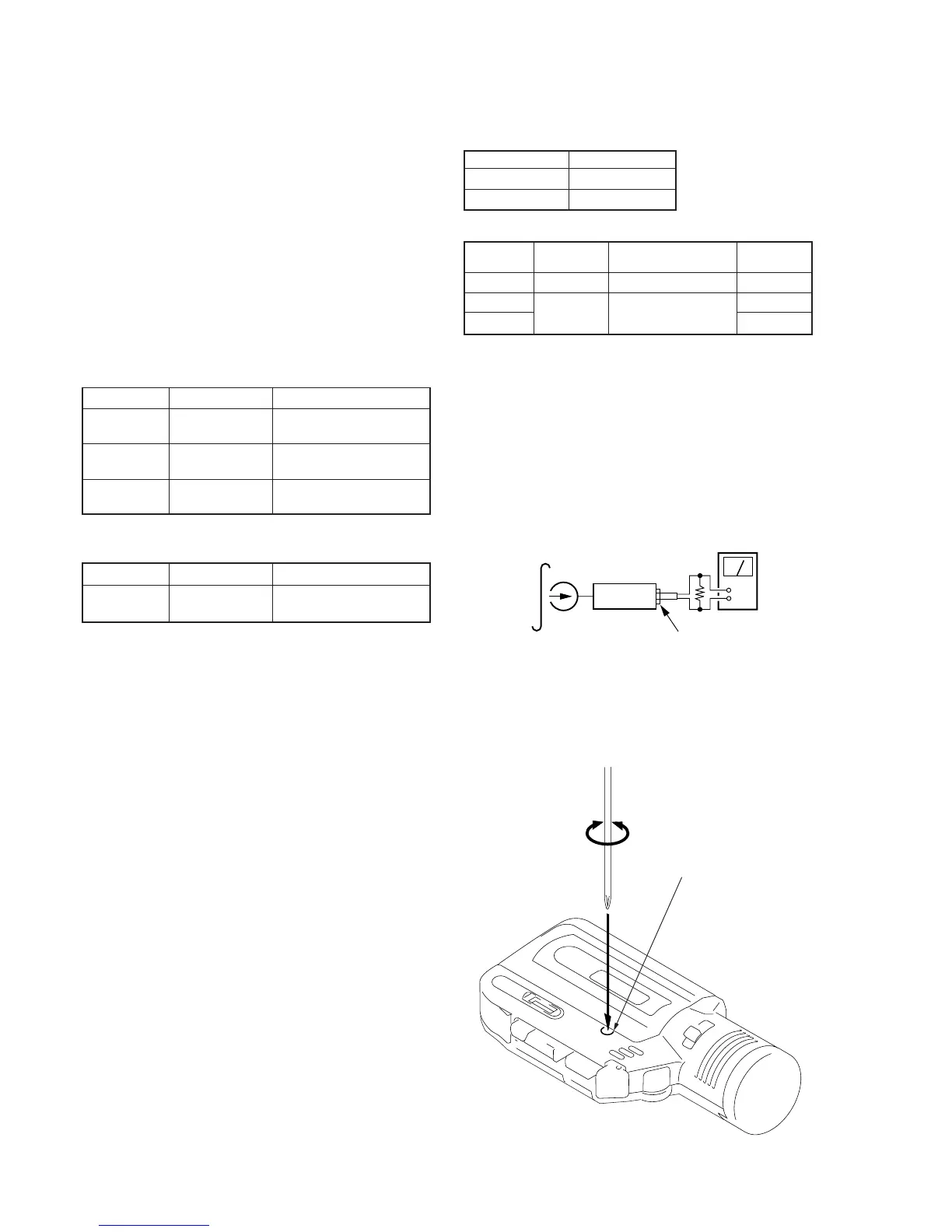

Torque Measurement

Tape Speed switch : 2.4cm

Mode Torque Meter Meter Reading

Forward CQ-103M

5 – 13 g • cm

(0.07 to 0.180 oz• inch)

Fast Forward CQ-201M

5 – 13 g • cm

(0.07 to 0.180 oz• inch)

Rewind CQ-201M

more than 20 g • cm

(more than 0.28 oz• inch)

Tape Tension Measurement

Tape Speed switch : 2.4cm/s

Mode Torque Meter Meter Reading

FWD CQ-403M

more than 30 g

(more than 1.06 oz)

3-2. ELECTRICAL ADJUSTMENTS

Standard Output Level

Output terminal EAR

Load impedance 10kΩ

Output level 78mV (– 20dB)

Test Tape

Type Signal Used for

Tape speed

(cm/s)

S-2-A030A 3kHz, –20dB Azimuth Adjustment 2.4

WS-24

3kHz, –10dB Tape Speed Adjustment

2.4

WS-12 1.2

0dB=0.775V

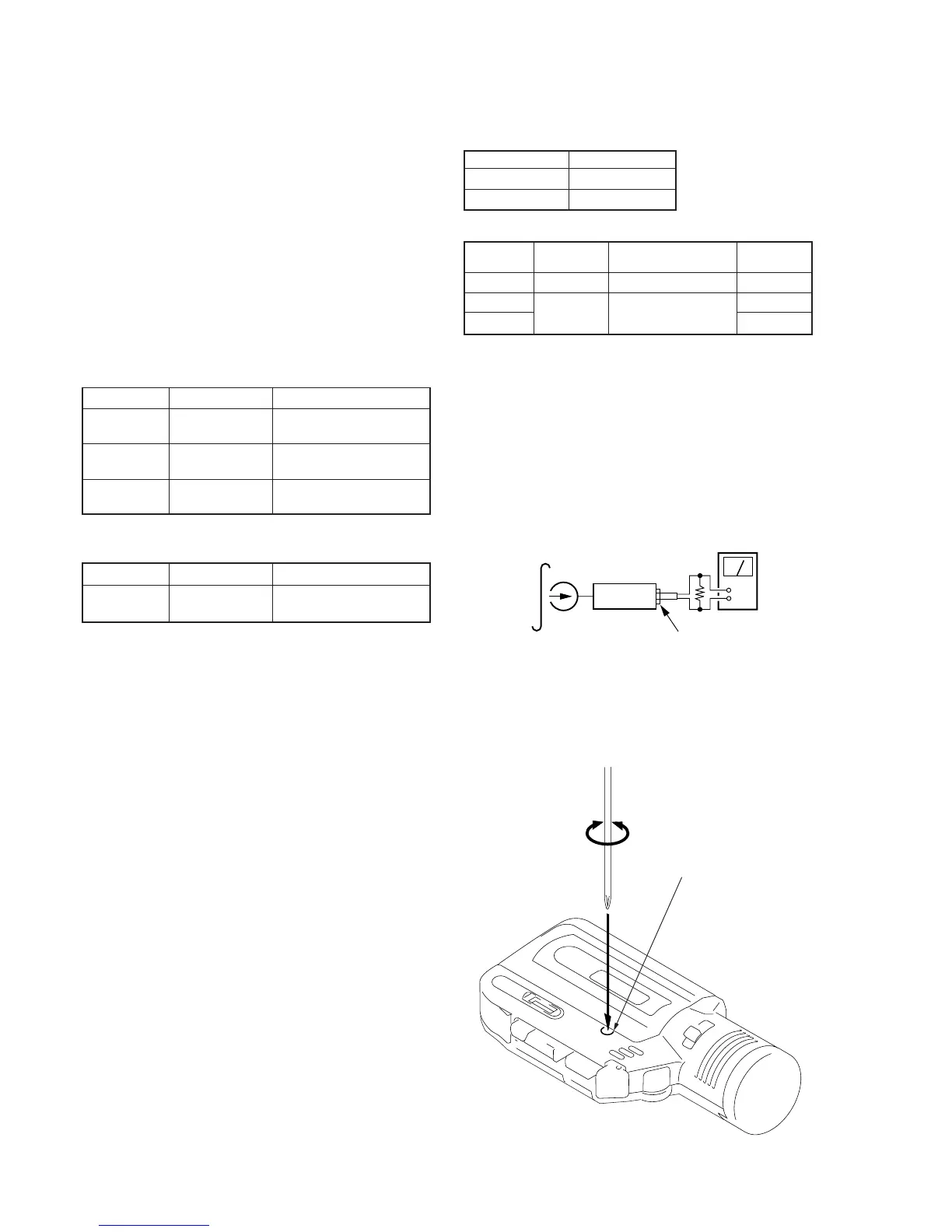

Record/Playback/Erase Head Azimuth Adjustment

Switch position

VOL control : Mechanical center

TAPE SPEED switch : 2.4cm

VOR switch : OFF

Procedure :

– FWD/REV playback –

• Rotate the screw to adjust level meter reading to the maximum.

Note : Adjust to the maximum peak though ther may be two or

three peaks

Adjustment Location :

set

test tape

S-2-A030A

(3kHz, –20dB)

level mete

Loading...

Loading...