— 6 —

SECTION 3

MECHANICAL ADJUSTMENT

SECTION 4

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcahol-moistened

sweb :

Playback head Pinch roller

Rubber belt Capstan

2. Demagnetize the playback head using a demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (3.0V) to

perform the adjustments.

Torqu Measurement

Mode

FWD

FWD

Back Tension

REV

REV

Back Tension

FF

REW

Torqu meter

CQ-102C

CQ-102RC

CQ-201B

Meter reading

20 - 30 g · cm

0.4 - 2.0 g · cm

20 - 30 g · cm

0.4 - 2.0 g · cm

More than 40 g · cm

PRECAUTION

1. Specified voltage : 3.0V

2. Switch position

DOLBY NR switch : OFF (EX172 MODEL)

AVLS switch : NORM

CASSETTE SECTION

Test Tape

Tape Speed Adjustmnet

Procedure :

1. Playback WS-48A (Tape center part) and adjust RV601 so that

the frequency counter reading becomes 3,000Hz ± 15Hz.

2. Playback WS-48A (Tape top and end).

Check that frequency counter reading is within 1.5% of the

reading of step1.

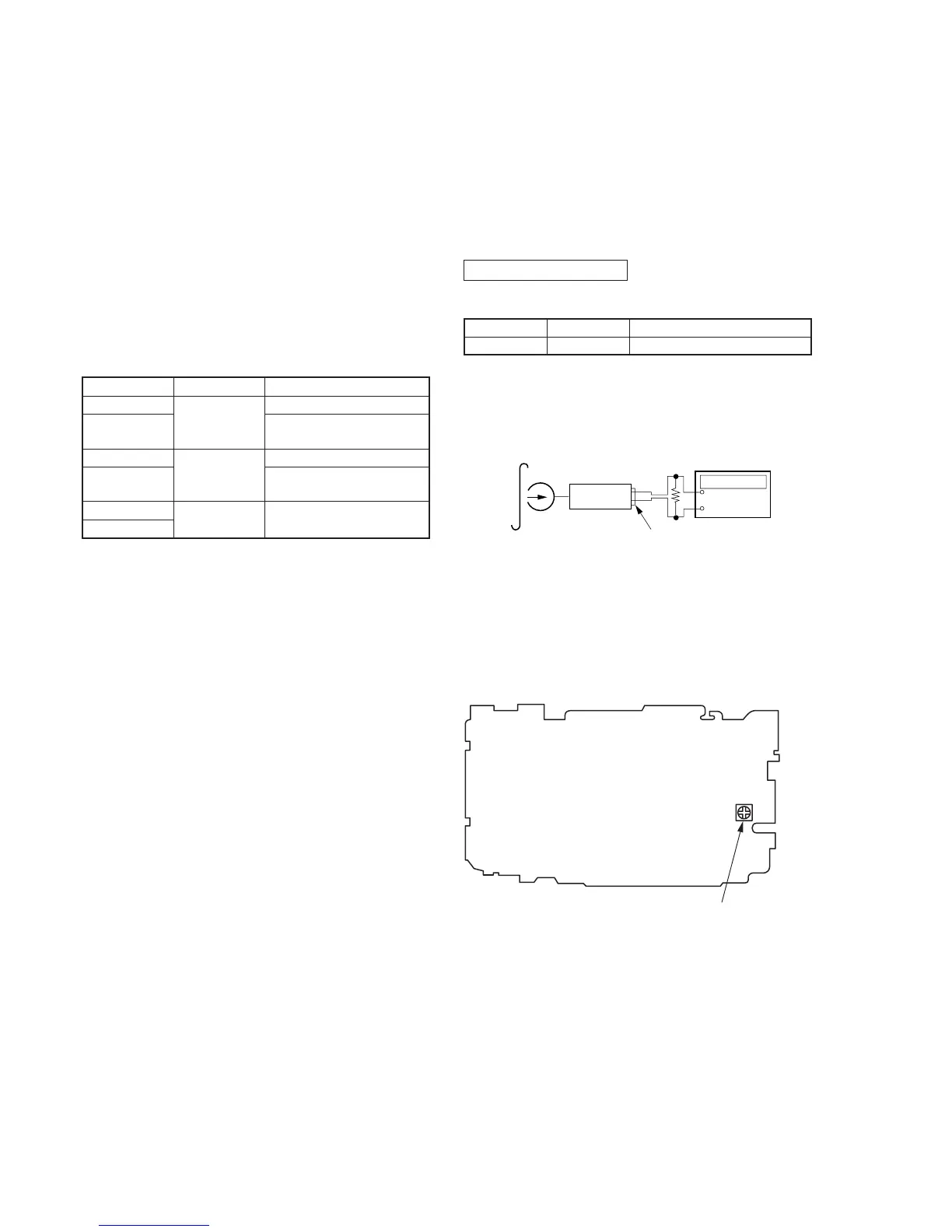

Adjustment Point :

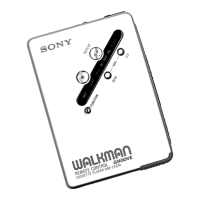

[MAIN BOARD] —CONDUCTOR SIDE —

Type

WS-48A

Signal

3kHz, 0dB

Purpose

Tape Speed Adjustment

Test tape

WS-48A

(3kHz, 0dB)

Set

16

Ω

PHONES jack

+

–

Frequency counte

Loading...

Loading...