XR-C5300X/C5305/C5600X

17 17

SECTION 5

MECHANICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idlers

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the power supply

voltage unless otherwise noted.

• Torque Measurement

Mode Tension Meter Meter Reading

more than 0.88 N

Forward CQ-403A more than 90 g

(more than 3.18 oz)

more than 0.88 N

Reverse CQ-403R more than 90 g

(more than 3.18 oz)

• Tape Tension Measurement

Mode Torque Meter Meter Reading

2.95 – 6.37 N•m

Forward CQ-102C 30 – 65 g•cm

(0.42 – 0.90 oz•inch)

Forward

0.05 – 0.44 N•m

Back Tension

CQ-102C 0.5 – 4.5 g•cm

(0.01 – 0.06 oz•inch)

2.95 – 6.37 N•m

Reverse CQ-102RC 30 – 65 g•cm

(0.42 – 0.90 oz•inch)

Reverse

0.05 – 0.44 N•m

Back Tension

CQ-102RC 0.5 – 4.5 g•cm

(0.01 - 0.06 oz•inch)

5.89 – 19.61 N•m

FF, REW CQ-201B 60 – 200 g•cm

(0.83 – 2.78 oz•inch)

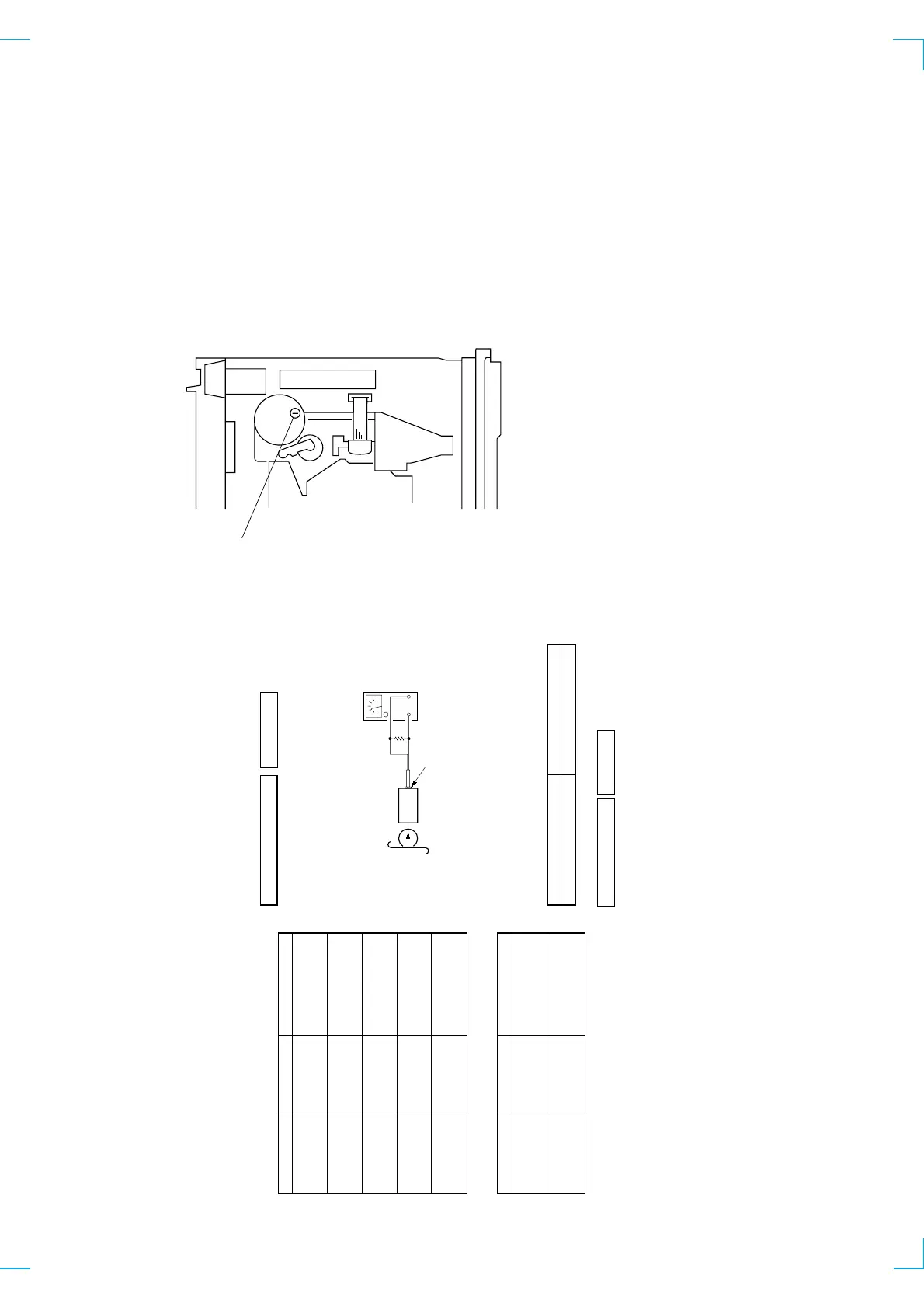

set

+–

test tape

WS-48A

(3 kHz, 0 dB)

AUDIO OUT jack (J331)

10 kΩ

speed checker

or

frequency counter

TUNER SECTION

0 dB=1 µV

The tuner section has no adjustment.

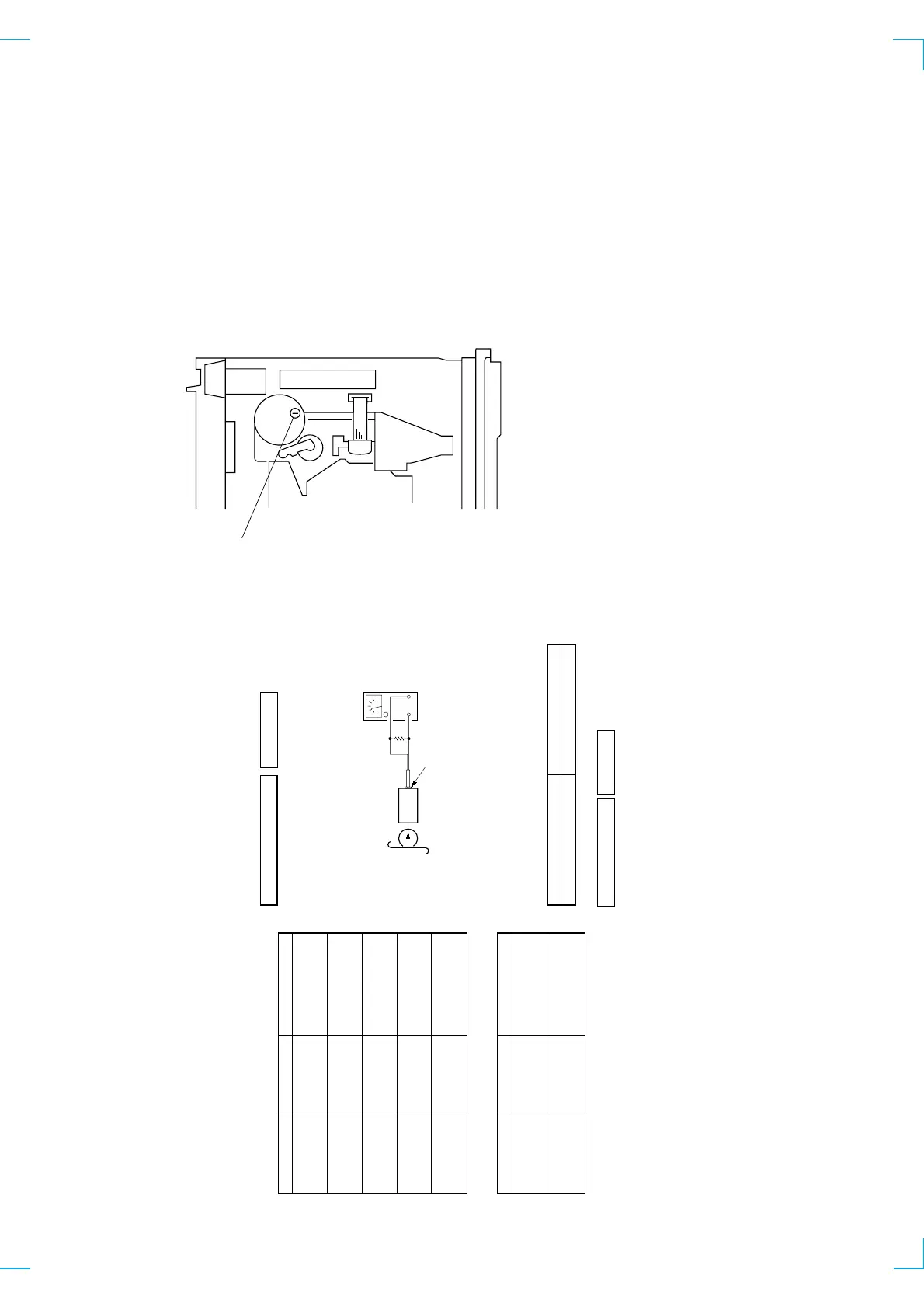

Adjustment Location:

– SET UPPER VIEW –

Tape Speed Adjustment

SECTION 6

ELECTRICAL ADJUSTMENTS

6-1. TEST MODE

<Set the Test Mode>

1. Set the “OFF” mode.

2. Push the preset

[4] button.

3. Push the preset

[5] button.

4. Press the preset

[1] button for more than two seconds.

5. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

0 dB=0.775 V

Speed checker Frequency counter

–1.5 to +2.5% 2,955 to 3,075 Hz

TAPE DECK SECTION

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the speed checker or frequency counter becomes in

specification.

Specification: Constant speed

Tape Speed Adjustment

Setting:

Loading...

Loading...