Checking the calibration of your pipe laser is easy. All you need is an engineer’s rule and your pipe

laser.

1. Select a level road, packing lot or field whose rise is not more than 4 inches in 100 feet

(10 cm/30 m).

2. Choose two points (A and B) about 100 feet (30 m) apart. The distance doesn’t have to be

measured, but the points must be found, so mark them well.

3. Set up the pipe laser just behind the lowest point and rough level.

4. Turn on the pipe laser and let it warm up for about 10 minutes.

5. Set the grade counter to 0.000%.

6. Aim the laser beam so that it passes over points A and B. Allow the pipe laser to self-level.

7. Accurately measure the elevation to the center of the beam at point A and record the elevation

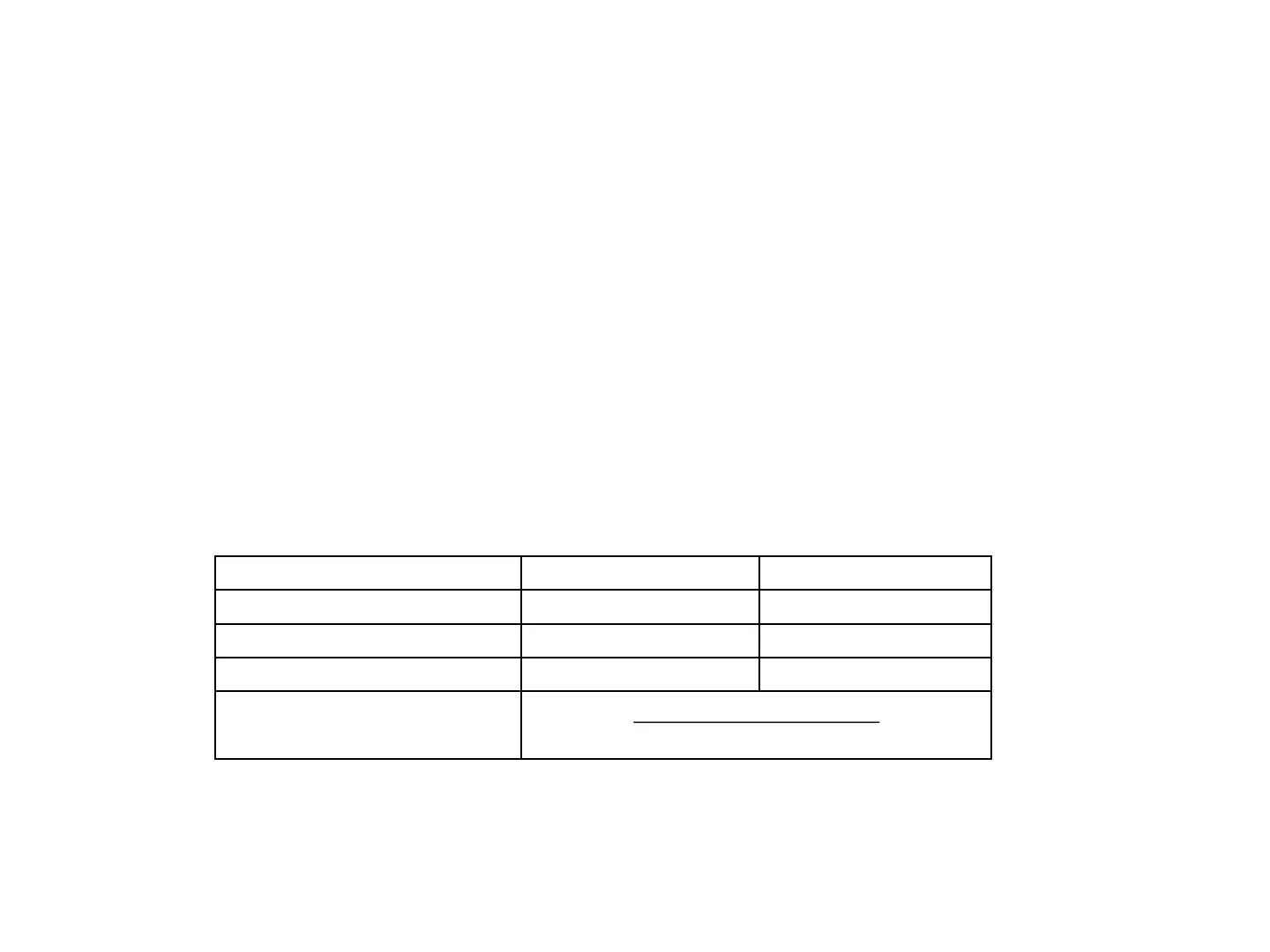

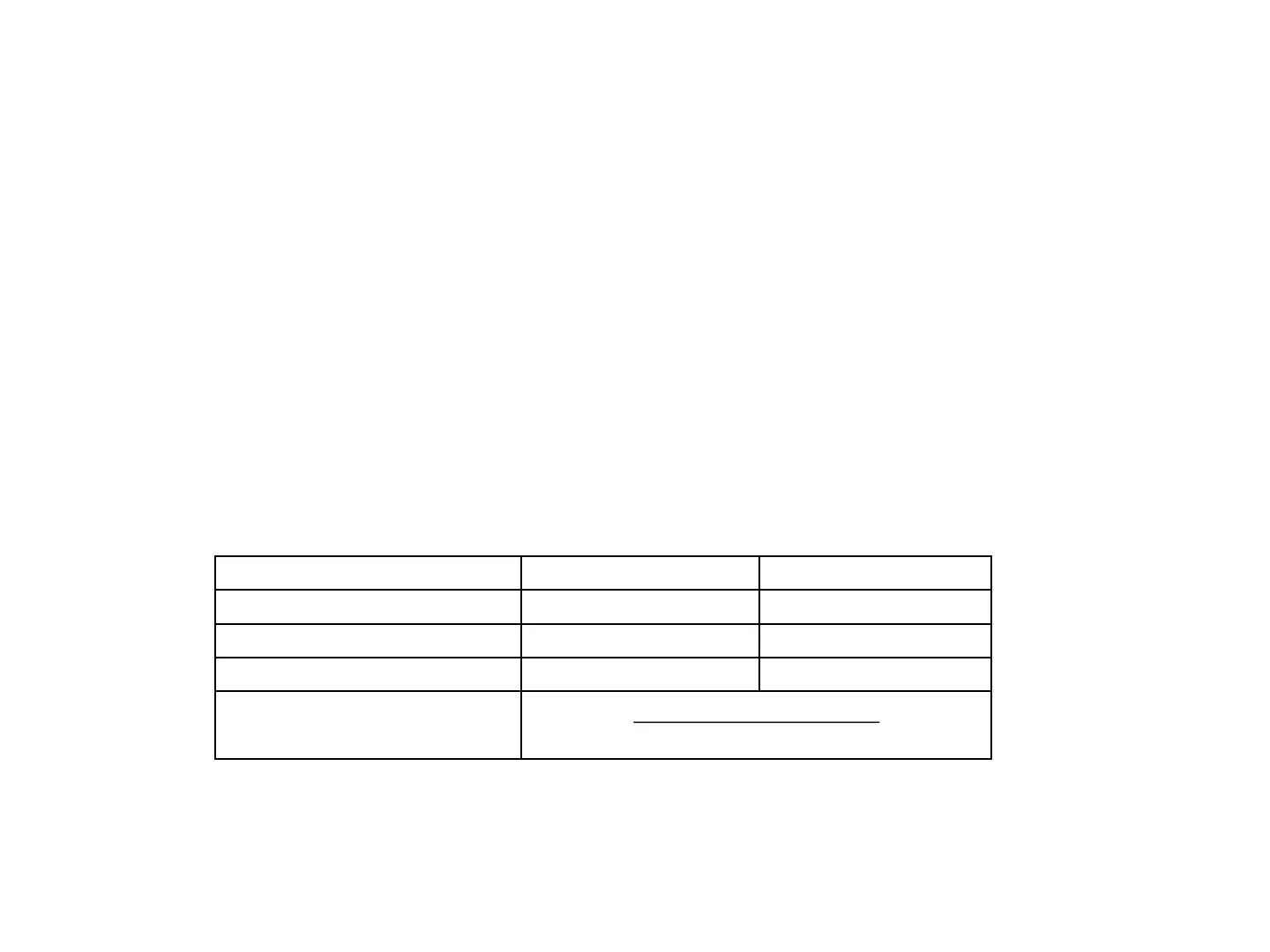

as A1 in a table like the one shown below.

Point A Point B

Second Reading A2 B2

First Reading A1 B1

Difference A2 - A1 B2 - B1

Error in 100 feet (30 m)

(A2 - A1) – (B2 - B1)

2

Loading...

Loading...