IM-S03-08 ST Issue 3

4

Screwed

Flanged

ScrewedFlanged

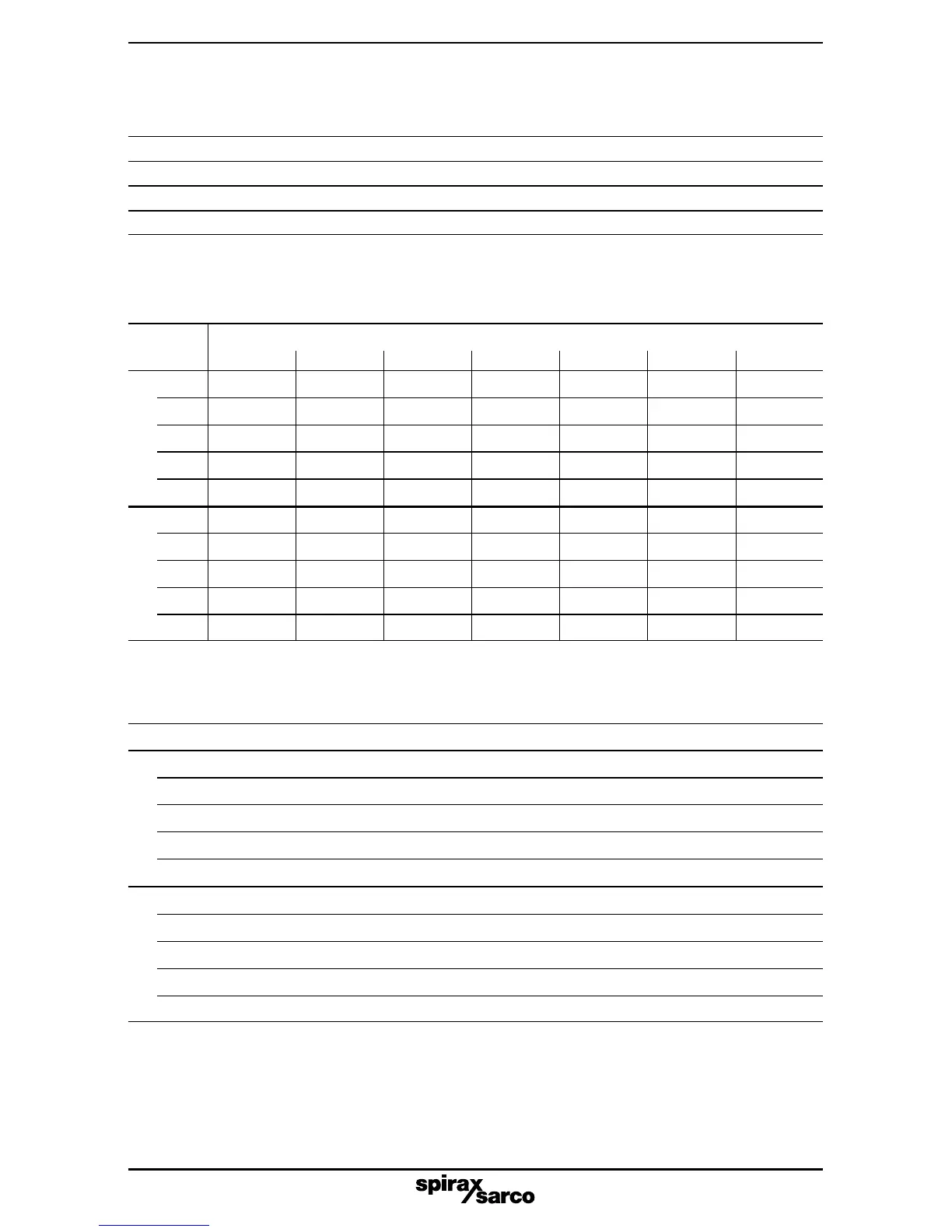

2.3 Limiting conditions (ISO 6552)

Maximum operating conditions depend upon orifice size.

Body design conditions exceeds PN16

PMA - Maximum allowable pressure 22 bar g @ 210°C (319 psi g @ 410°F)

TMA - Maximum allowable temperature 210°C @ 22 bar g (410°F @ 319 psi g)

Designed for a maximum cold hyraulic test pressure of: 34 bar g (493 psi g)

Note: The pressure limit on the flange type used should be greater than the pressure limit of

the internal mechanism (DPMX) selected.

DPMX - Maximum differential pressure bar

DPMX - Maximum differential pressure bar

Size

2 2.5 4 8.5 12.5 13.8 17

½" 211/12 - 211/10 211/8 - 211/7 211/6

¾" 212/16 - 212/12 212/10 - 212/8 212/7

1" 213/24 - 213/20 213/16 213/14 - 213/12

1½" 215/36 - 215/28 215/22 215/20 - 215/18

2" - 216/48 216/40 216/32 216/28 - 216/24

DN15 221/12 - 221/10 221/8 - 221/7 221/6

DN20 222/16 - 222/12 222/10 - 222/8 222/7

DN25 223/24 - 223/20 223/16 223/14 - 223/12

DN40 225/36 - 225/28 225/22 225/20 - 225/18

DN50 - 226/48 226/40 226/32 226/28 - 226/24

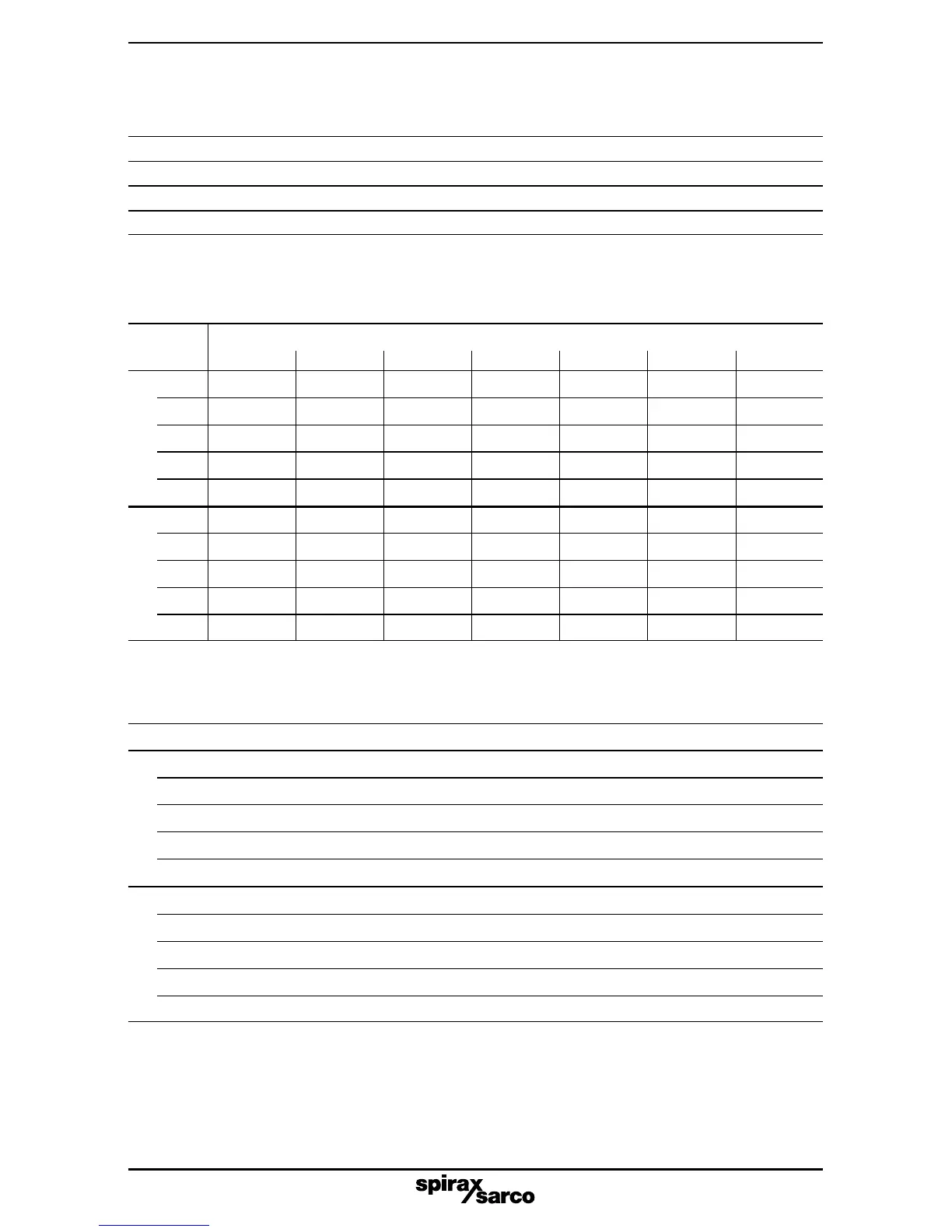

2.4 Dimensions / weights (approximate) in mm and kg

TypeSizeABCDWeight

Type 211 ½" 163 108 178 67 2.8

Type 212 ¾" 200 135 229 93 5.2

Type 213 1" 269 188 280 114 12.2

Type 215 1½" 365 238 380 140 27.0

Type 216 2" 432 286 470 185 43.5

Type 221 DN15 215 108 254 - 4.9

Type 222 DN20 286 135 280 - 9.1

Type 223 DN25 305 188 305 121 16.3

Type 225 DN40 370 238 380 140 30.8

Type 226 DN50 450 286 457 165 49.4

Loading...

Loading...