4. Install a small gate valve in the sensing line so that this

can be closed when servicing the regulator.

5. The sensing line must be pitched downward from the

main valve to insure proper drainage.

6. To permit accurate setting of the pressure regulator,

a pressure gauge should be installed as close as pos-

sible to the pilot sensing line connection.

Bypass

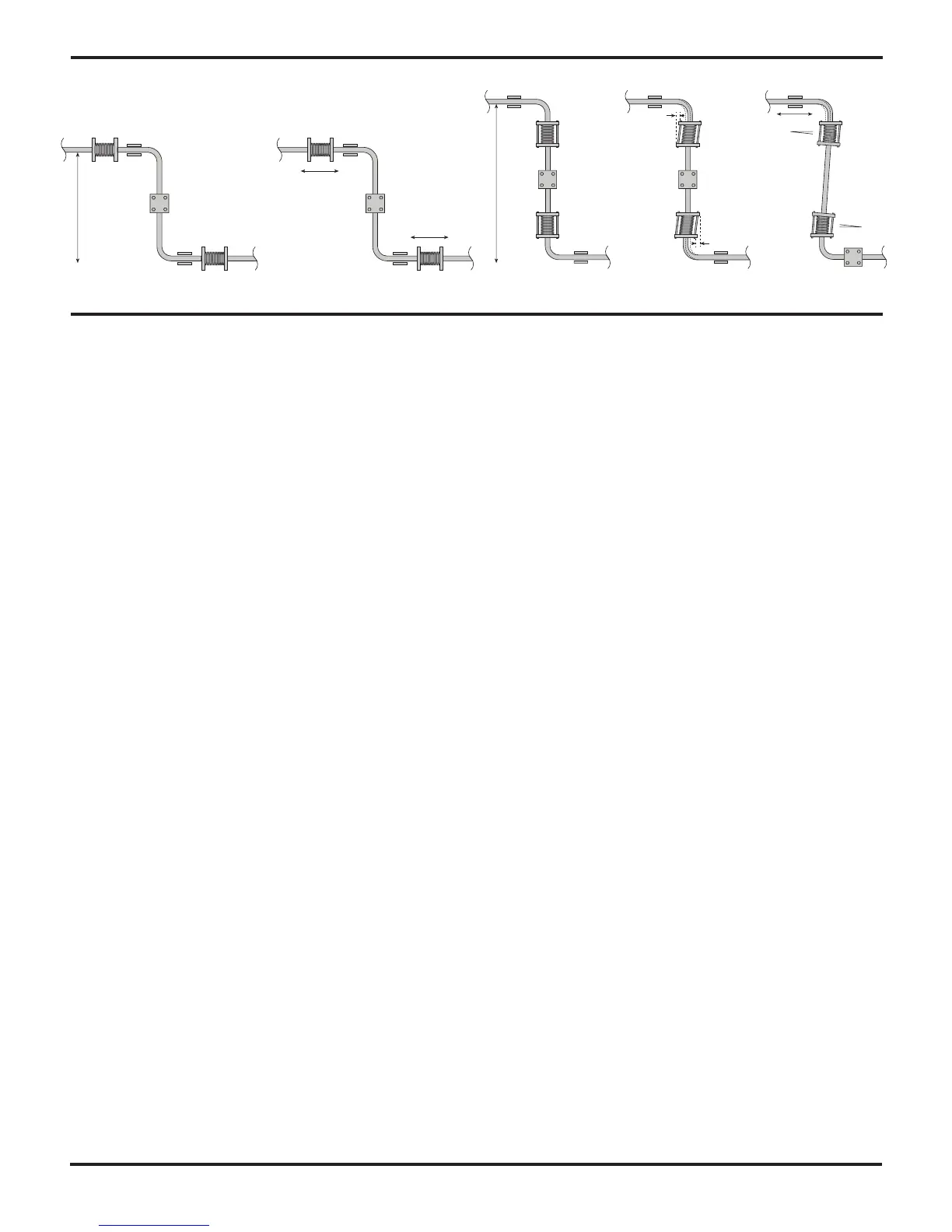

1. A bypass connection, as shown in Figs. 1 and 2, is

recommended so that the valve can be serviced with-

out shutting down the equipment.

2. The bypass valve should be the same size as the

pressure reducing valve.

Steam Line Drain Trap

1. To insure proper operation of the valve and avoid

premature wear, it is recommended that a 1/2” Spirax

Sarco thermodynamic steam trap be installed on the

steam supply line. (See Figs. 1 and 2.)

2. A steam trap should also be installed in the down-

stream piping at the heel of each rise, between all

reducing valves installed in series, and ahead of any

manual or automatic valve. This will prevent conden-

sate accumulation that can result in waterhammer

damage.

Pipeline Strainers

1. It is strongly recommended that strainers be installed

before the reducing valve and steam traps.

2. Make certain adequate clearance is provided for

screen removal and blowdown connection between

strainer and valve body.

Stop Valves

All stop valves on the supply side, as well as on the

downstream side of the pressure reducing valve and

sensing line, should be of the gate type so as to insure full

rated capacity and good control.

Separators

It is recommended that a line size separator is installed

before all pressure reducing stations where the pipeline

supply is longer than 50 ft from a trapping station or

where exposure or piping configurations lead to the accu-

mulation of significant amounts of condensate ahead of

the PRV station.

Installing the Valve

Unpack Carefully

Do not lift the regulator by the tubing. Grasp the body of

the valve firmly when lifting.

Piping

1. Typical hookup sketches as shown in Figs. 1 and 2 will

aid in planning a correct installation.

2. Piping on the downstream side of the valve should be

increased so as not to restrict flow.

3. Swage nipples are recommended for changes in pipe

sizes.

4. Before installing the valve make sure the piping is free

of foreign material, scale, etc.

5. Make certain the arrow cast on valve body is pointing

in the direction of flow.

6. Valve should always be installed in a horizontal posi-

tion. (See Figs. 1 and 2.)

7. Pressure Gauges must be installed on both sides of the

reducing valve.

Assembling Pilot to Valve Body

1. Remove all protective caps from ports if present.

2. Remove the package of square gaskets from the pilot

box and install on the main valve cover assembly (A).

3. Install pilot on top of gasket just placed on main valve

cover assembly (A) so that the sensing line is pointing

in same direction as the valve outlet connection. Be

sure that the guide pin in the cover assembly (A) fits

securely in the guide hole in the pilot. Be sure the pilot

bolts are secured to the valve cover assembly (A) and

tightened.

Pilot Pressure Sensing Line

1. Copper tubing (1/4” OD) can be used for the sensing

line with suitable compression fittings or as alternative

1/4” piping can be used.

2. Connect the sensing line to a straight portion of the

piping 10 pipe diameters from nearest fitting down-

stream from the valve and approximately 1 foot from

elbows, tees, valves and other restrictions. (See Figs. 1

and 2.)

3. When the reducing valve is serving a single piece of

equipment, the sensing line can be connected to the

steam space of the equipment.

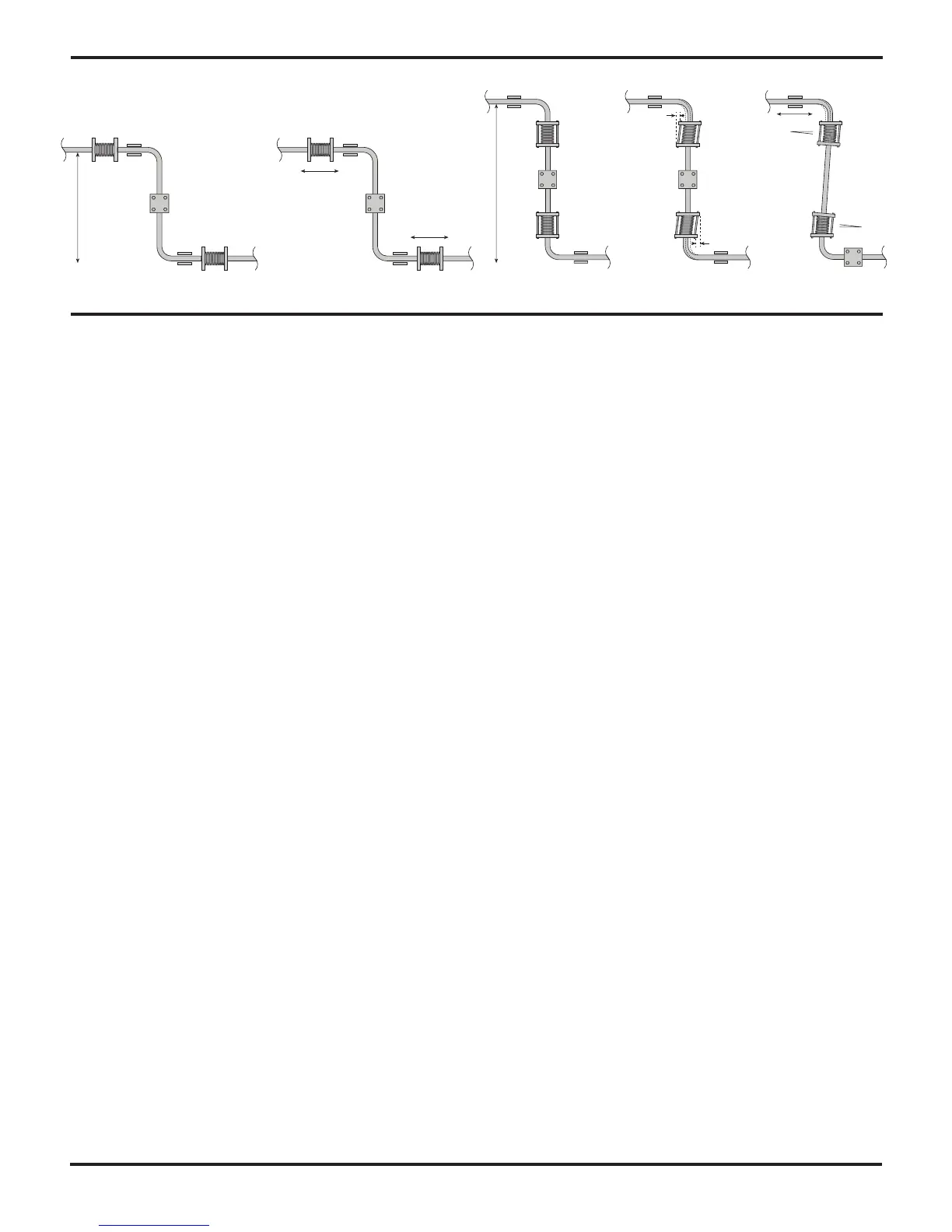

Thermal expansion:

Short

distance

Fixing point

Axial movement

Axial movement

Guides

Guides

Guides

Guides

Limit rods

Limit rods

Fixing point

Medium

distance

Small

lateral

movement

Small

lateral

movement

Large

lateral

movement

Large

lateral

movement

Loading...

Loading...