5

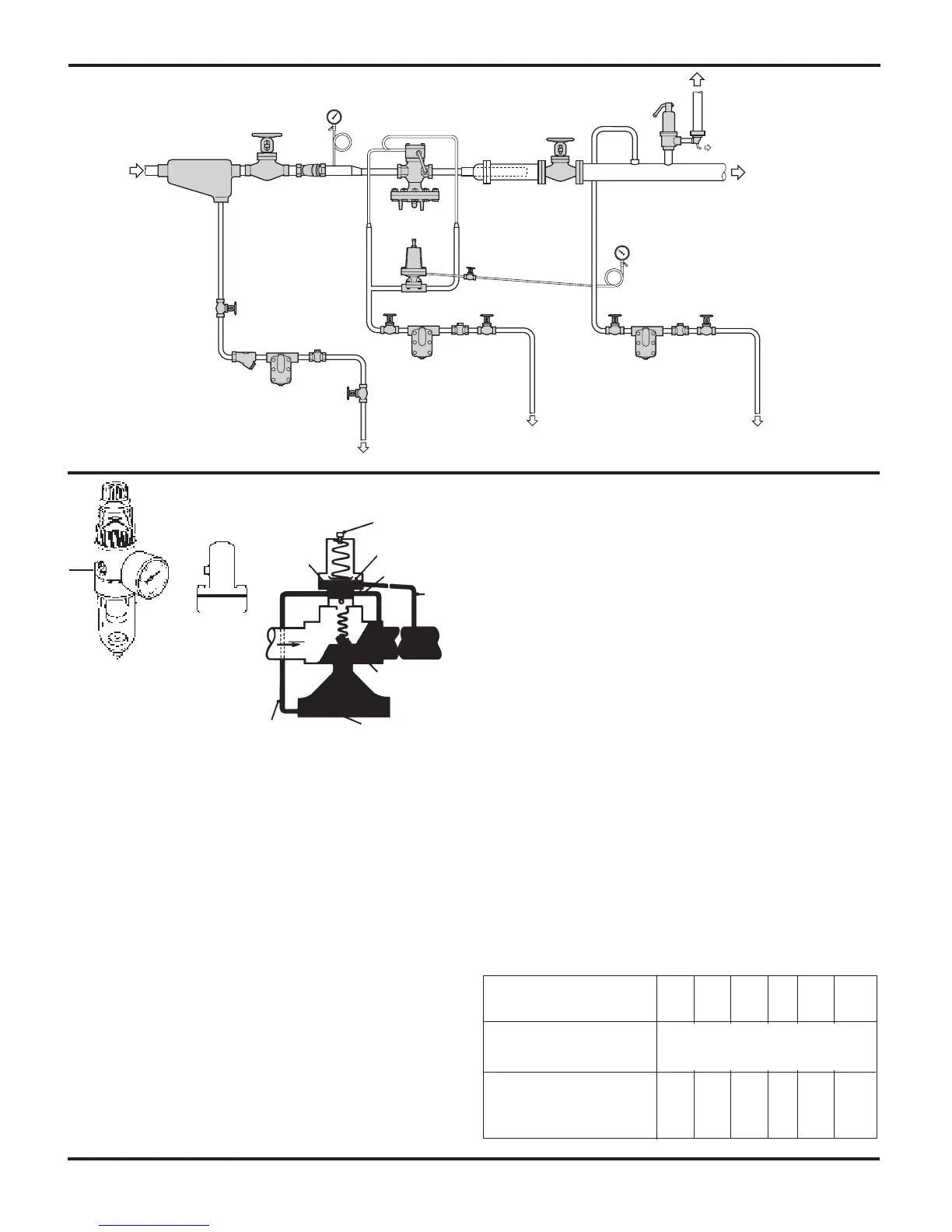

Pressure Adjustment,

Spring or Air

Pressure

Pilot

Pressure Diaphragm

Downstream

Pressure

Sensing Line

Orifice

Main Valve

Main Diaphragm

Control Pressure

How the 25P & 25PA Work

Normal positions before start-up are with the main valve

closed and the pilot valve held open by spring force or

air pressure. Entering steam passes through the pilot

valve into the main diaphragm chamber and also out

through the control orifice. As flow through the pilot

valve exceeds flow through the orifice, control pres-

sure increases in the diaphragm chamber and opens the

main valve. As steam flows through the main valve, the

increase in downstream pressure feeds back through the

pressure sensing line to the underside of the pressure

diaphragm. When the force below that diaphragm bal-

ances the compression force of the spring above it, the

pilot valve throttles. The control pressure maintained in

the main diaphragm chamber positions the main valve to

deliver just enough steam for the desired delivery pres-

sure. Adjustment of the spring or air pressure above the

pressure diaphragm changes the downstream pressure

set point. When steam is no longer required, the sensing

line pressure increases closing the pressure pilot and the

control pressure bleeds back through the control orifice.

This allows the main valve to hold the desired reduced

pressure, and it may close tight for a dead-end shutoff.

Start-up

1. First make certain that all stop valves are closed.

2. Remove pilot spring cover then turn the pressure pilot

adjustment (2D) counter-clockwise until spring is slack.

Make certain spring remains in vertical position and

centered in its retainers.

Air loaded PA pilots must have no air pressure

supplied to them.

3. Open stop valves in the following order:

a. Open stop valve ahead of steam trap on steam

supply line. This will insure water free steam at the

regulator inlet when put into operation.

b. Open small gate valve on pressure sensing line.

c. Slowly open inlet stop valve.

4. Slowly adjust pilot spring at (2D) turning clockwise until

reduced pressure required is indicated on pressure

gauge downstream of valve.

5. Once the system has stabilized itself, slowly open

down-stream isolation valve. It may be necessary

to make re-adjustment of pilot spring (2D). Replace

spring cover then tighten adjustment locknut.

6. Important ––Retighten all pilot flange connections to

insure steam tight joints.

7. Air Loading PA Pilot requires air loading as indicated

in the following table.

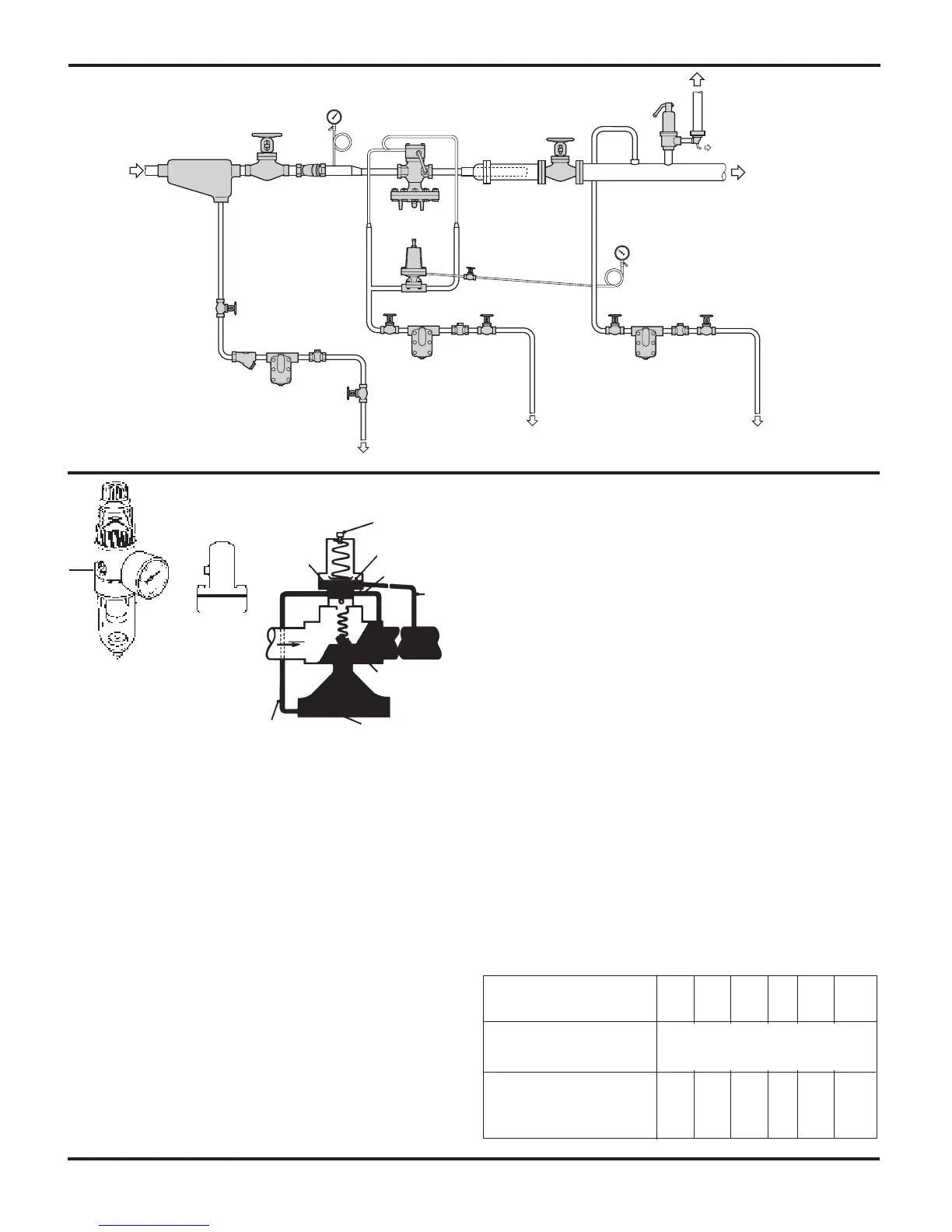

Hook-up for Remote Operation of

25 PRM Pressure Reducing Valve

Float &

Thermostatic

Steam Trap

Float &

Thermostatic

Steam Trap

Float &

Thermostatic

Steam Trap

Strainer

Strainer

Safety

Valve

Steam

Supply

Moisture

Separator

Main

Control Valve

Remote

Pressure

Pilot

Limit pilot to 15 ft.

drop below main valve

and drain all sup-

ply tubing. If pilot is

mounted above main

valve, pilot line drip

traps can be elimi-

nated. For longer dis-

tance an air loaded

pilot should be used.

Drip

Pan

Elbow

Reduced

Steam

Pressure

Check

Valve

Check

Valve

Check

Valve

Noise Diffuser

(if required)

5/16” Copper

Tubing or 1/4” Pipe

1/2” Pipe

Desired Outlet Steam

5 10 25 50 75 100

Pressure P2 psig

Inlet Pressure

P1 psig

Approximate 11 16 31 56 80 102

Air Set Pressure to to to to to to

psig 13.5 16.8 33.5 58 81 103

10 psig to 100 psig

MPC2

Filter Regulator

Air

Pilot

Loading...

Loading...