Do you have a question about the Spirax Sarco 25P and is the answer not in the manual?

| Action | Direct acting |

|---|---|

| Operating Temperature | -10°C to +80°C (14°F to 176°F) |

| Ambient Temperature | -20°C to +60°C (-4°F to 140°F) |

| Type | Pneumatic valve positioner |

| Materials | Stainless steel |

Confirms product suitability for intended application, fluids, materials, and operating limits.

Ensures safe working conditions including access, platforms, and adequate lighting.

Addresses risks from pipeline contents and surrounding hazardous environments.

Considers system impact, pressure isolation, and safe venting procedures.

Ensures availability of correct tools, genuine parts, and appropriate protective clothing.

Details requirements for permits to work and safe manual handling practices.

Addresses residual hazards like hot surfaces and necessary protection against freezing.

Provides guidelines for product disposal and information required for returns.

Safe handling procedures for cast iron products, considering its brittle nature.

Guidelines to prevent damage from pipe misalignment during installation.

Methods to prevent water hammer, including steam trapping on steam mains.

Instructions for careful unpacking and preparing piping for valve installation.

Recommendations for upstream/downstream piping, swage nipples, and flow direction.

Steps for assembling the pilot to the valve body and connecting the pressure sensing line.

Guidance on bypass connections, drain traps, strainers, stop valves, and separators.

Diagram and instructions for remote operation setup of the 25 PRM valve.

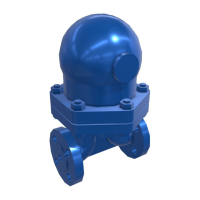

Explanation of how the 25P and 25PA pressure reducing valves function.

Step-by-step instructions for the initial start-up of the pressure reducing valve.

Diagnosing and resolving pressure overshoots under normal and light load conditions.

Identifying causes and cures for the valve not opening, including diaphragm and orifice issues.

Troubleshooting insufficient delivery pressure, considering valve undersizing and supply pressure.

Addressing issues where the valve does not shut off properly, including bypass leaks.

Routine checks for strainers, valve seats, orifices, and joints for leaks.

Steps to diagnose valve malfunctions by checking pilot valve and main valve seating.

Procedures for inspecting and replacing pilot valve head, seat, and diaphragms.

Instructions for inspecting and replacing the main valve head and seat for 1/2"-4" sizes.

Procedures for inspecting and replacing main valve diaphragms for 1/2"-4" and 6" sizes.

Specific steps for servicing the main valve head and seat on 6" size valves.

Lists main valve components and part identifiers for different valve size ranges.

Details on recommended spares kits for general maintenance purposes.

Explains how steam expands and increases velocity across reducing valve seats.

Guidance on using the chart to determine suitable pipe sizes for steam capacities.

Demonstrates finding optimal upstream and downstream pipe sizes using the velocity chart.

Loading...

Loading...