Valve Sizes 1/2” Thru 4”

Inspecting and Replacing Main Valve

Diaphragms (Refer to Figs. 5, 6, 7, and 9)

1. Unscrew copper tubing connection at (G).

2. Remove main valve diaphragm bolts (1C).

3. This will allow the lower diaphragm case to be

removed.

4. The 2 metal diaphragms (1H) should be inspected to

insure that they have not become distorted or possibly

fractured as a result of abnormal operating conditions.

5. At the same time any accumulation of dirt or foreign

material should be removed from the diaphragm case.

6. The valve stem should also be checked to make sure

it is free to move and that there is no scale or foreign

material lodged in the guide bushing (1F).

7. Before reassembling diaphragms in 1/2” thru 4”

sizes, main valve head must be in place and head

in a closed position with the return spring and

main valve cover.

8. Make certain pressure plate (1G) is set properly.

(Refer to Fig. 5.)

9. Care should be taken in centering the diaphragms

properly and equalizing bolt take-up uniformly.

6” Valve Only

Inspecting and Replacing Main Valve

Diaphragm, Seat, and Head Assembly (Refer

to Fig. 8)

Diaphragms

1. Unscrew copper tubing connections (G) to lower dia-

phragm chamber.

2. Remove main valve diaphragm bolts (1C) and drop

lower diaphragm case.

3. The 2 metal diaphragms (1H) should be inspected and

replaced if they have become distorted or fractured.

4. Clean any accumulation of dirt from the diaphragm

case and orifice (H).

Servicing the Main Valve Head and Seat

5. Loosen the diaphragm plate set screw and remove

the diaphragm plate (1G).

6. Remove the top cover bolts (1A) and cover.

7. Remove the stem and head assembly from the valve.

Inspect the head and seat for wear.

8. Check the body erosion around the seat ring.

9. Replacement seats and heads should be lapped in,

and minor wear can be corrected by lapping with 400

grit compound.

10. On re-assembly be sure diaphragm plate (1G) is set

and set screw securely tightened.

NOTE: For replacement parts refer to Spirax Sarco

Replacement Parts Reference Guide.

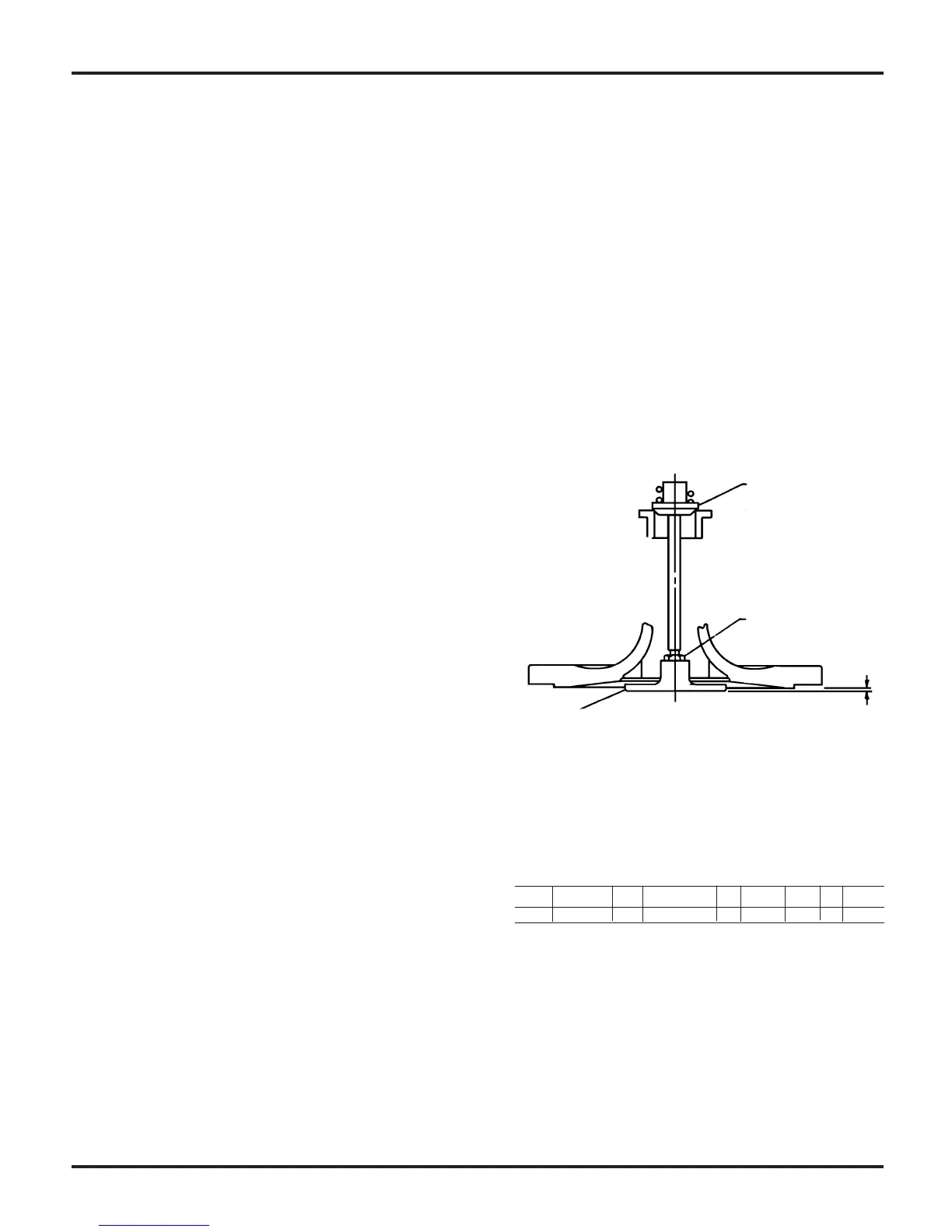

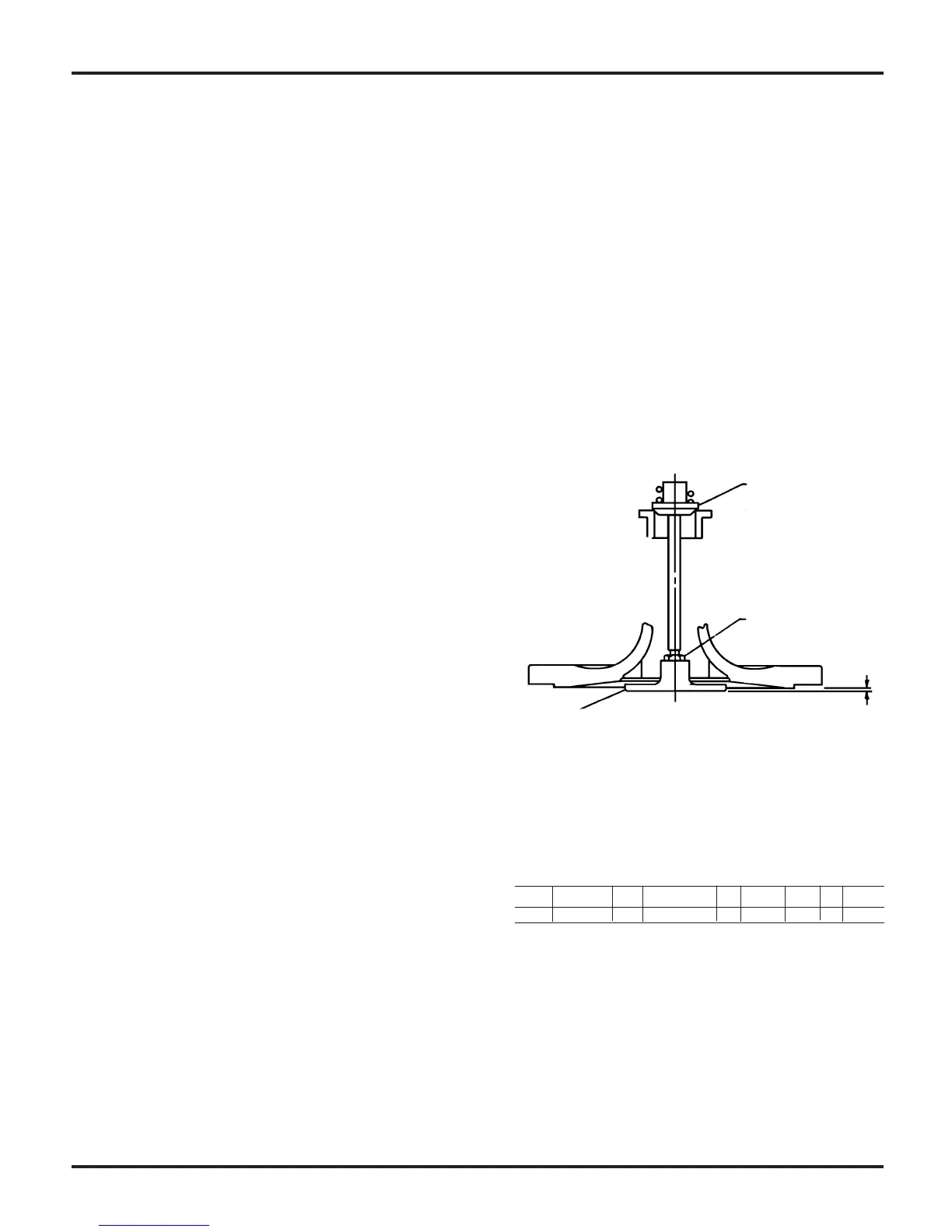

Fig. 5––Note in 1/2” and 4” sizes, top of valve must be

completely assembled and head must be on seat when

measuring dimension “A” and when re-assembling

diaphragms.

Size 1/2” & 3/4” 1” 1-1/4 & 1-1/2” 2” 2-1/2” 3” 4”

Dim. A 1/16” 5/64” 3/32” 1/8” 13/64” 13/64” 1/4”

Head on Seat

Adjustment

& Locknut

Pressure Plate

1G

8

Loading...

Loading...