11

Inlet over the plug

(DN150,DN200e250

withbalancingdisc)

Inlet below the plug

(DN15÷150)

Fig. 2

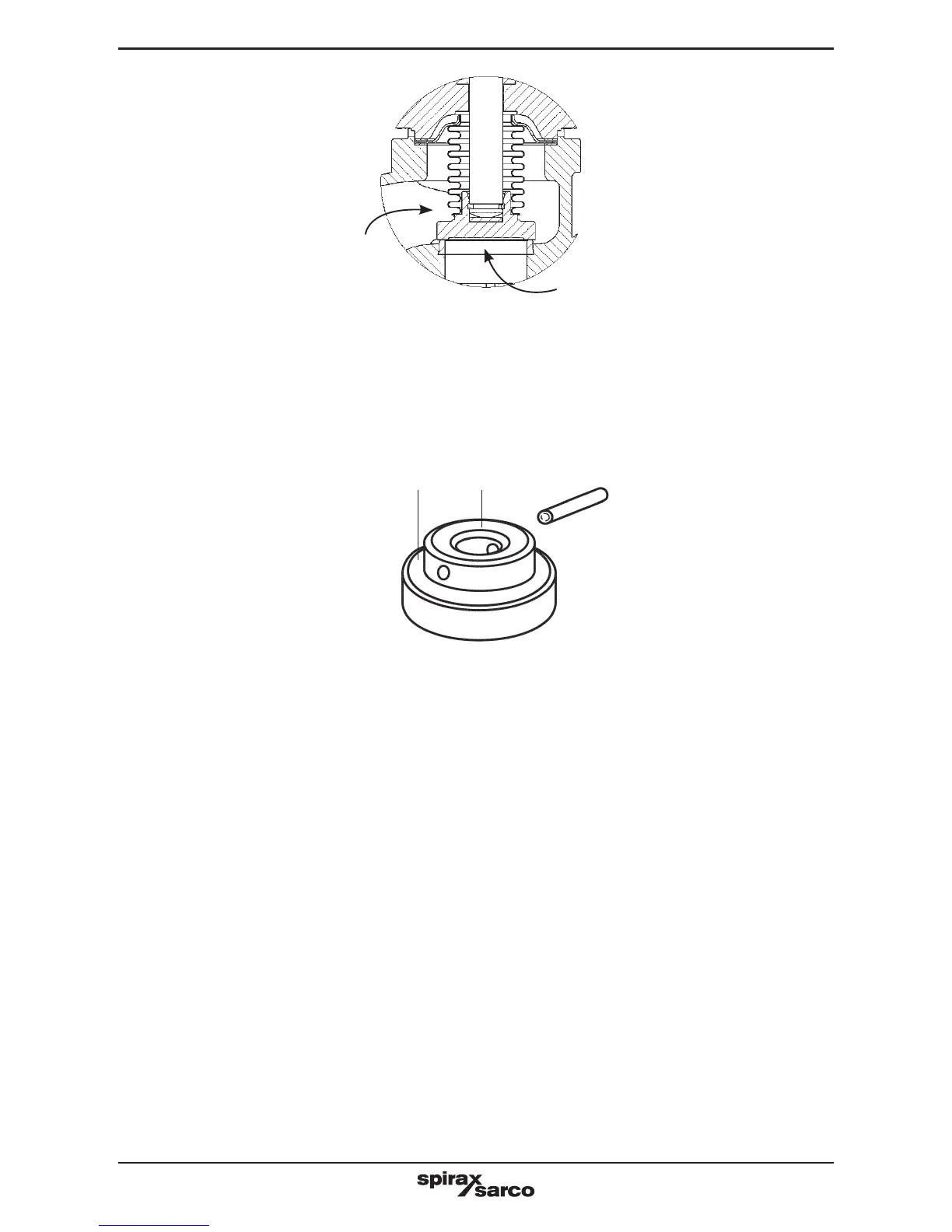

Note: Thebalancingdiscisatwo-stageinternalby-passdevice(Fig.3)whichsignicantlyreduces

themotionforceofthehandwheelintheeventofhighdierentialpressures.Whentherststage

opens,itactsasapre-openingpilotplugandallowsacontrolledowofuidtopass.Thisgradually

reducesthedierentialpressurepresentbetweenupstreamanddownstreamthevalveand,asa

result,reducestheforcerequiredtoliftthesecondstage(mainplug)fromitsseat.Typically,large

on/ovalvesaresubjectedtohighdierentialpressuresevenundernormaloperatingconditions.

Therefore, the closure of these valves would be almost impossible without the balancing disc.

Fig. 3

2°

stage

1°

stage

These valves are not designed to withstand severe stress, so the mounting pipelines should be

suitablymounted,alignedandproperlysupportedinordernottotransmitanyadverseeectsof

expansion(thrust,torsionandexing movements may causeleakages,deformationandand/or

non-allowablestresstovalvebodies).Inaddition,allcouplingandsealingcomponentsshouldbe

constructedwithmaterialsthatareallowableandcompatiblewiththesystemspecications.During

valveassembly,angesshouldbeperfectlyalignedandgasketsperfectlycentred,carefullycleaned

and should not present any signs of damage, in order to ensure perfect tightness. Evenly cross-

tightenthebolts,respectingrecommendedtighteningtorques(Asshowninthetableonpag.10)to

avoid over-tightening which might produce further stress over the whole structure.

Note:valvesandpipelinesworkingwithhigh(>50°C)orverylowtemperatures(<0°C)should

beinsulatedbysuitableinsulatingjacketsinordertopreventdirectcontactwithpersonnel.Ifthis

isnotpossible,providesuitablewarningsignboardsinproximityoftheunits/pipingthatrepresent

hazardousconditions.Ifitisnecessarytoinsulatethevalves,makesurenottocompromisetheir

correctoperation.Thegasketbetweencoverandstungboxmustalwaysremainperfectlyvisi-

ble and accessible. During welding, coating and/or brickwork operations, valve should always be

suitably protected from welding residue or drops as well as from dust, sand/grit or other building

materials. Moreover, screws, spindle and all plastic parts should never be painted to avoid their

possible malfunction.

Insteamplants,itisalwaysadvisabletoinstallathermodynamicoraoatingcondensatesteamtrap

upstream of the isolation valves, to ensure the adequate condensate drainage in order to protect

valves,equipment,downstreaminstrumentsandpipingfromdamagesduetowaterhammereects.

To remove any foreign bodies or impurities that may damage the gaskets surfaces, before com-

missioningthesystemallpipelinesshouldbethoroughlywashedandushedwithcompressedair,

with valves in fully open position.

Loading...

Loading...