12

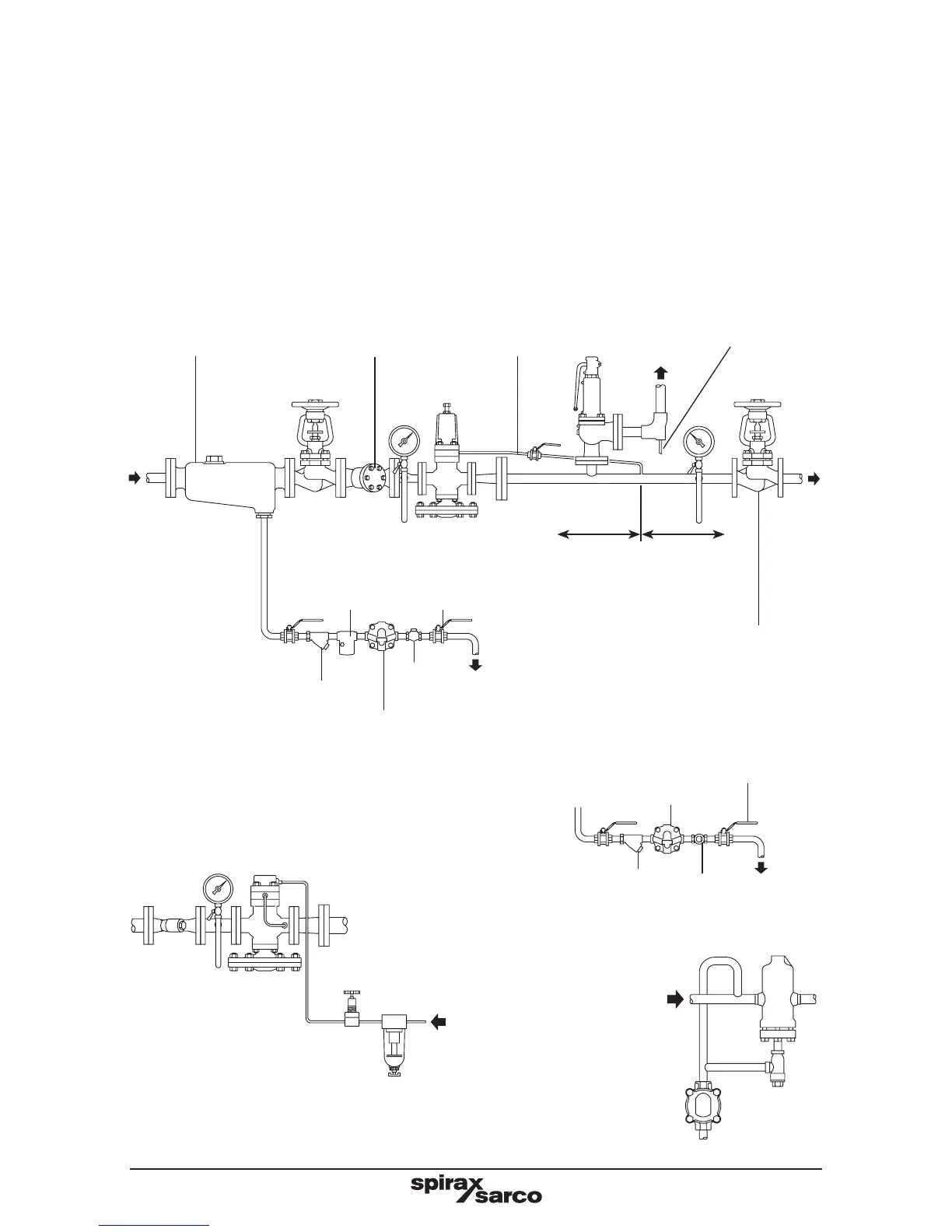

Pressure

control

pipe

Small bore

drain

Strainer with 100 mesh

stainless steel screenSeparator

Steam

supply

Spiratec

sensor

chamber

Float type

steam trap

Pressure

reducing valve

DP17 and DP17E

0.9 m, (3 ft) or 15 pipe

diameters clear on either side

See Section 3.6, page 13.

Downstream isolating valve to

provide no-load conditions for

setting pressure reducing valve

Safety

valve

Discharge

pipe

Ball valve

Check

valveStrainer

3.2 Fitting (Figs. 4, 5 and 6)

The valve should always be fitted in a horizontal pipeline with the main diaphragm chamber

below the line (Fig. 4). To meet high capacities or widely varying loads, or where stand-by

facility is required, two or more valves may be used in parallel (Fig. 5). For pressure turndown

in excess of 10 to 1 consideration should be given to using the two valves in series. To

avoid instability pipework volume between the valves should be equivalent to at least 50

pipe diameters in length of the intermediate correctly sized pipework. To ensure adequate

drainage of the space between the two reducing valves a trap set should be fitted as shown

in Fig. 6.

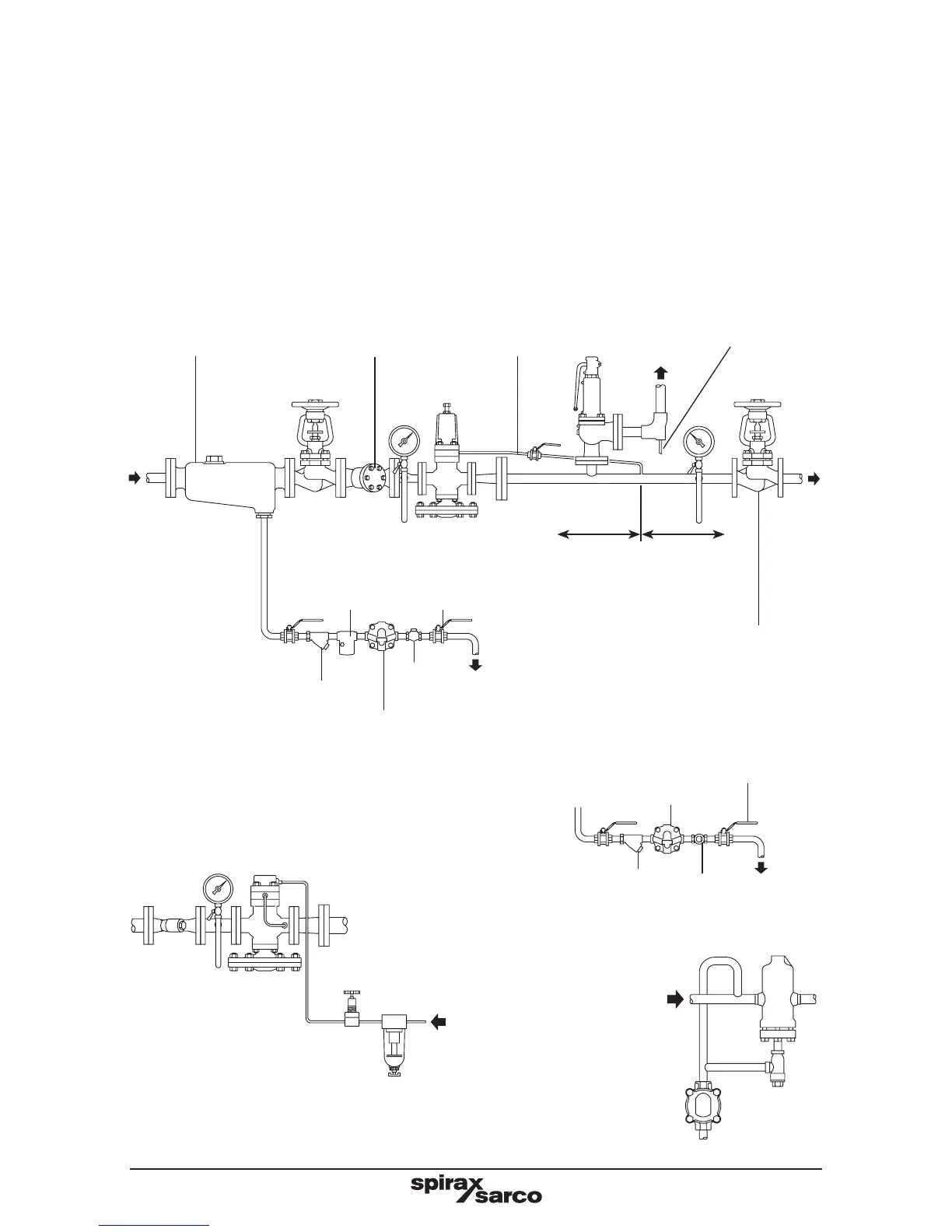

Separator

Compressed

air

Fig. 4 Recommended installation

Installation for

compressed air

(DP17G and DP27G)

Compressed

air trap

DP17R

Compressed

air

Regulator

Filter

Float type

steam trap

Alternative for

draining separator

Strainer Sight glass

Ball valve

Loading...

Loading...