13

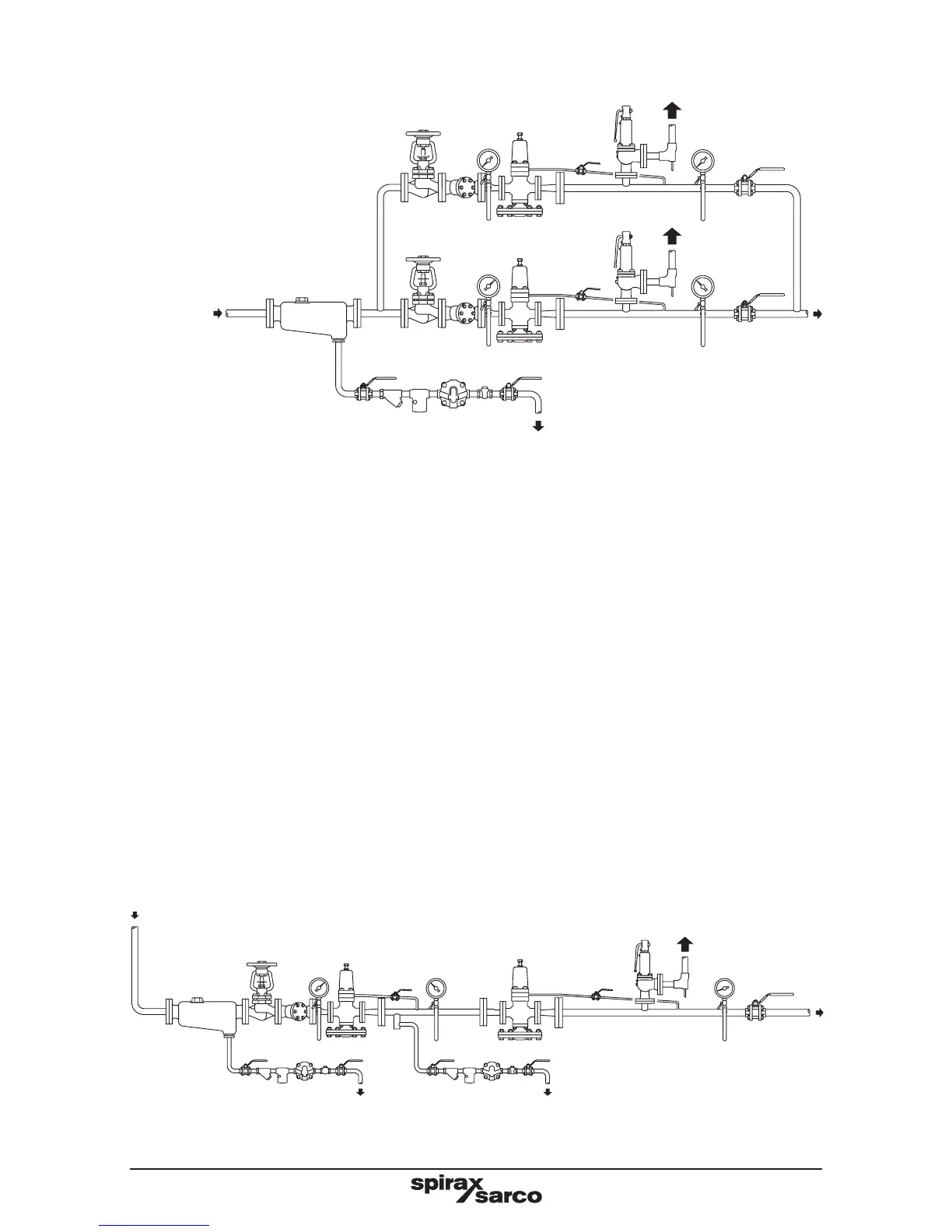

Fig. 5 Two pressure reducing valves in parallel

Steam supply

] See Section 3.6

3.3 Pipeline sizing

The piping on both sides of the valve must be sized so that velocities do not exceed

30 m/s (98 ft/s). This means that a properly sized valve will often be smaller than the

connecting pipework.

3.4 Pipeline stresses

Line stresses caused by expansion or inadequate support should not be imposed on the

valve body.

3.5 Isolating valves

These should preferably be of the full bore type.

3.6 Removal of condensate

It is recommended that a separator with trap set is fitted upstream of the valve to ensure

dry steam conditions.

If there is a rise in the low pressure line from the valve then a further drain point should be

provided to keep the valve drained after shutdown.

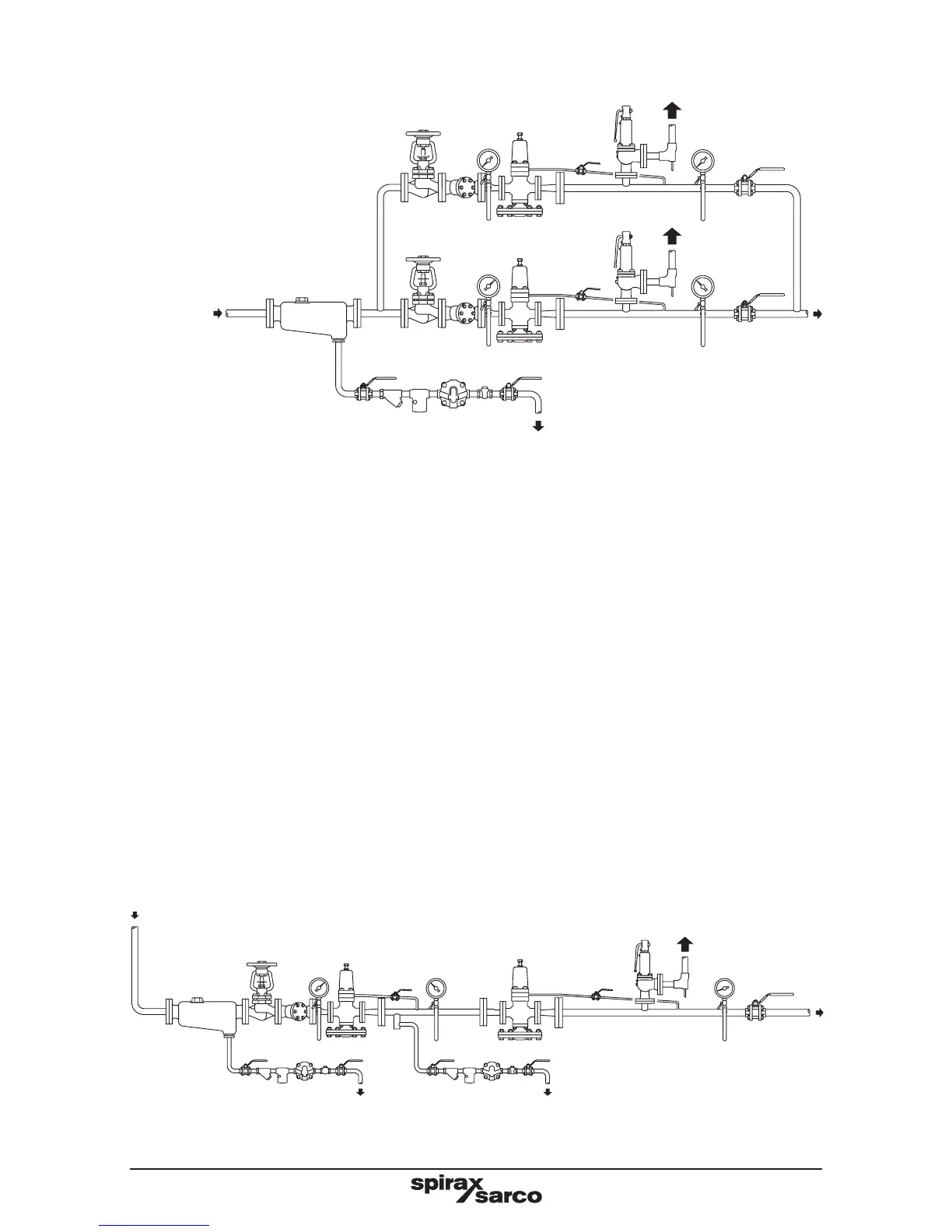

Steam supply

] See Section 3.6

Fig. 6 Two pressure reducing valves installed in series

]

]

]

Loading...

Loading...