IM-S24-15 CH Issue 4

16

- Refit the valve plug /stem assembly by carefully sliding the valve stem in order to pass

through the seals.

- Using a new bonnet gasket refit the bonnet (2) onto the valve body, ensuring the plug is

on the valve seat, and replace the nuts and tighten to the recommended torque (see Table 1,

page 13), ensuring that the valve plug is centrally located in the seat whilst tightening.

- Screw down the gland nut until it just starts to compress the packing. Compress the gland

seal packing by tightening the gland nut (8) by 1½ turns. Raise and lower the valve stem

after each tightening of the gland nut to encourage the seals to bed down correctly.

- Ensure that the valve spindle is able to travel fully open and fully closed a minimum of

5 times to ensure a smooth operation.

- Tighten the gland nut (8) by approximately ½ turn to ensure seats are under load and

re-stroke the valve.

- Commission the actuator according to the appropriate Installation and Maintenance

Instructions.

- Bring the valve back into service.

- Should there be a small amount of seepage from the valve stem, this may be stopped by

carefully tightening the gland nut. Care should be taken not to overtighten as this may cause

the spindle to lock-up.

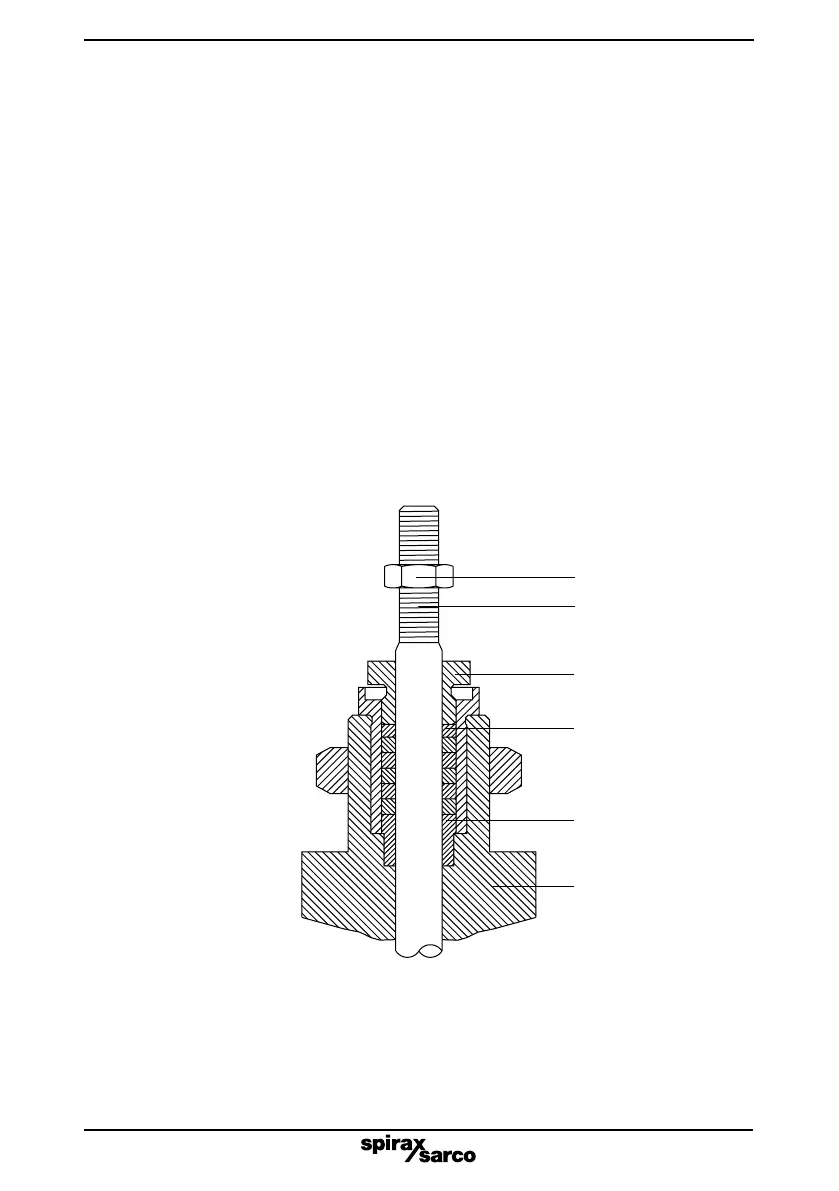

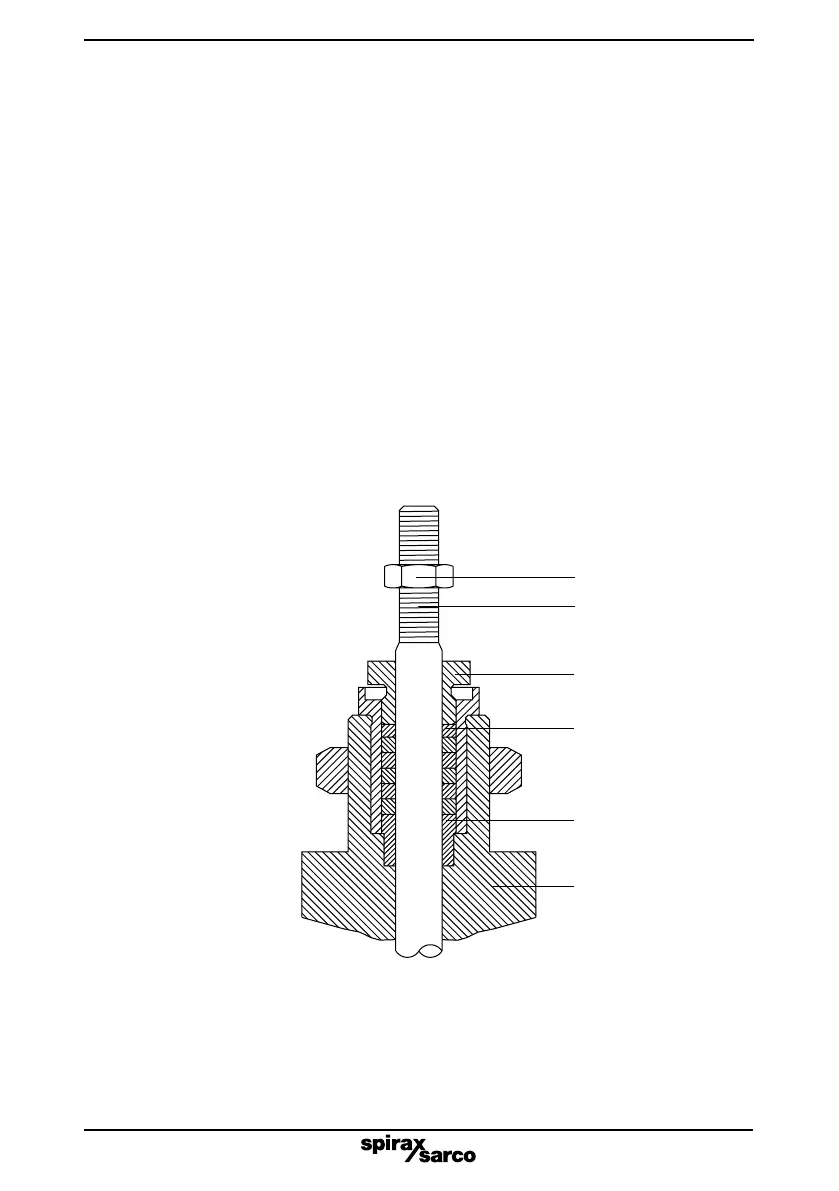

Fig. 4

7

5

8

10

15

2

Loading...

Loading...