11

APV_DA4_UK-1_102018.indd

UK

Double Seat Mix Proof Valve

APV DELTA DA4

Instruction Manual: UK - rev. 1

APV

6. Cleaning

In the cleaning process of DA4 valves, distinction is made between

three areas: Flow areas, Seal surfaces and seat area, and Leakage

chamber.

6.1. Flow areas

The CIP-fluid cleans the upper and lower passages of the valve

during CIP.

6.2. Seal surfaces and seat area

The seal surfaces of the upper area (upper shaft and seat seal) and

the lower area (lower shaft and seat seal) are flushed and cleaned

when the individual valve shafts are lifted during cleaning. The seat

area and leakage chamber are also cleaned during this process.

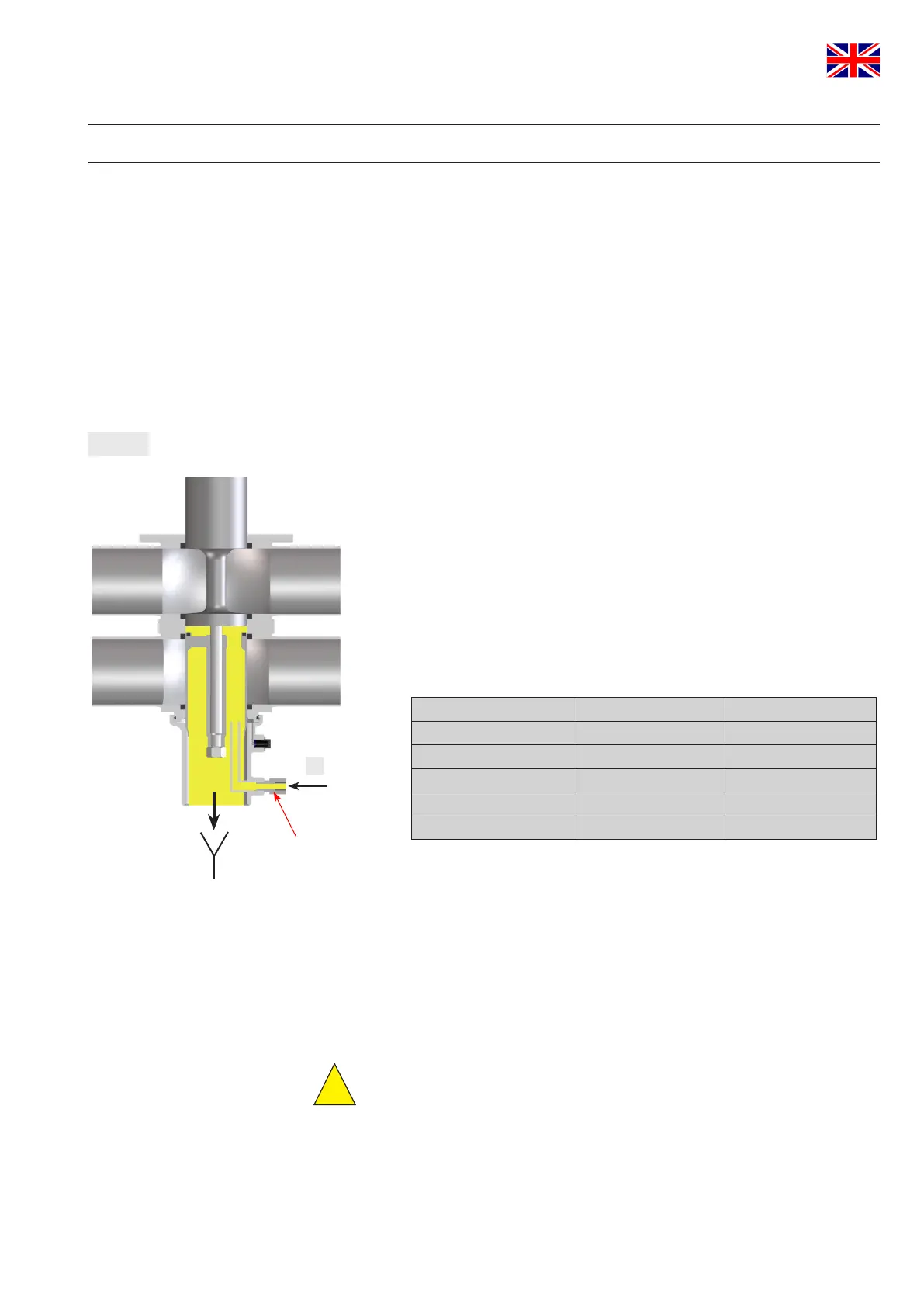

6.3. Leakage chamber

CIP spraying cleans the leakage chamber. The cleaning connection

is at item C in fig. 6.3.

CIP spraying does not produce pressure build-up in the leakage

chamber. SPX FLOW recommends performing CIP-spraying in

the closed valve position; however, it can also be done in the open

valve position.

Under standard conditions 15 valves DN 40-100 / 1,5"-4" can be

cleaned via one spray distribution line DN 25.

6.4. Cleaning recommendation

Cleaning steps Seat lifting cycle CIP spraying

pre-flushing – 3 x 10 sec.

caustic flushing 80°C 3 x 5 sec. 3 x 10 sec.

intermediate flushing 2 x 5 sec. 2 x 10 sec.

acid flushing 3 x 5 sec. 3 x 10 sec.

subsequent flushing 2 x 5 sec. 2 x 10 sec.

- The lifting cycles refer to a cleaning pressure of p = 2-5 bar.

- Depending on the pressure ratio, cleaning temperatures, cleaning

steps and degree of soiling, different cycles must be adjusted.

- Flushing quantities per CIP spraying cycle:

DN 40-100/1,5-4" about 1,2 ltr/10s

- Cleaning pressure at CIP cleaning connection: min. 2 bar

max. 5 bar

Caution!

The cleaning liquid applied must be compatible with the respective

seal material.

C

CIP spraying

free drain

CIP liquid

fig. 6.3.

!

Loading...

Loading...