8

APV_SD4_ATEX_UK-0_122018.indd

UK

Double seal valve

DELTA SD4-ATEX

Instruction Manual: UK - rev. 0

APV

6. Cleaning

For the cleaning of SD4 valves, distinction is made between two

areas.

6.1. Theflowchambers

The passages of the valve are cleaned by the cleaning liquid during

cleaning of the connected pipelines.

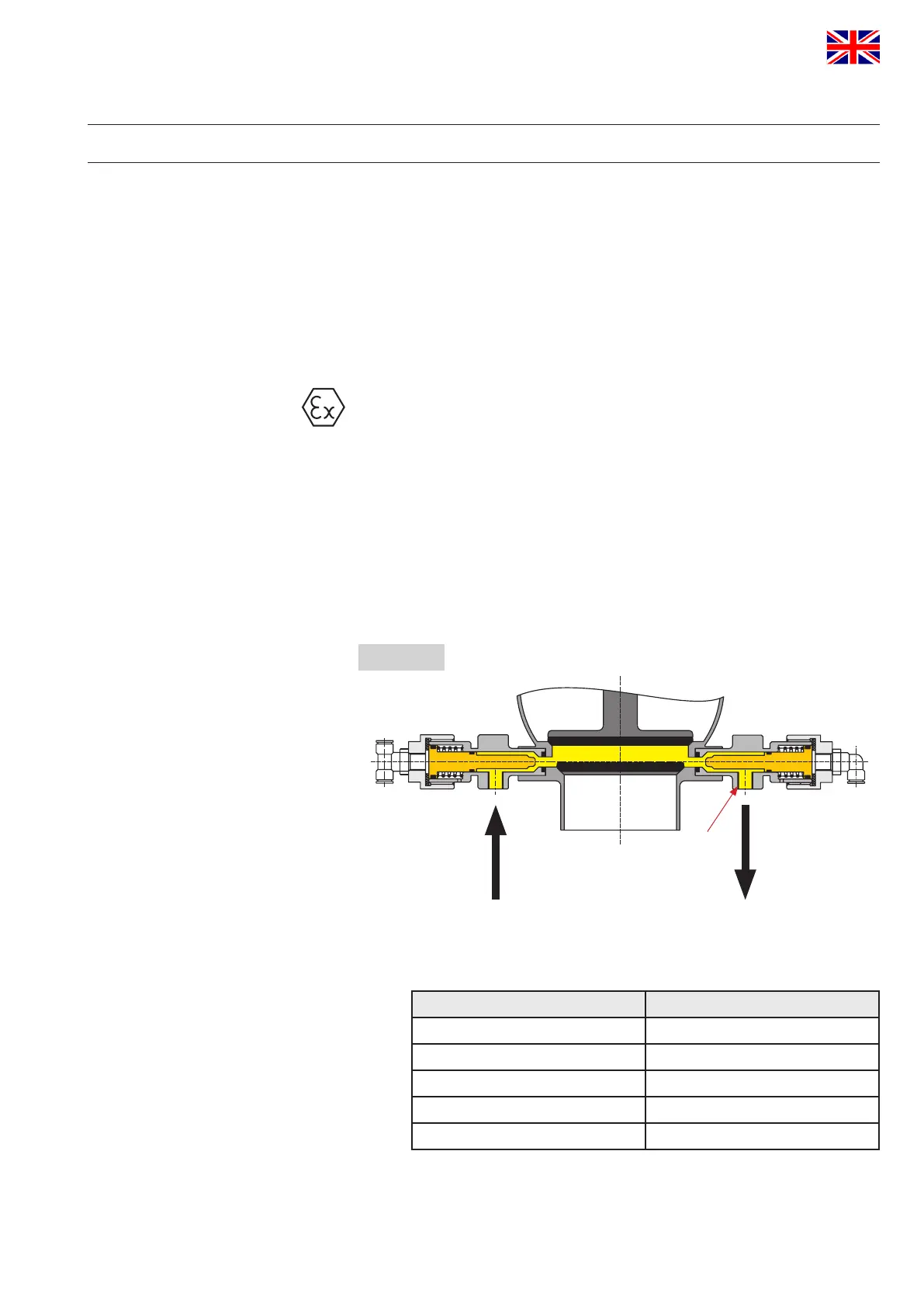

6.2. Theleakagechamber(fig.6.2.)

Cleaning of the leakage chamber is undertaken via the leakage

valves. The cleaning liquid is supplied via one leakage valve and

discharged to the atmohsphere in a closed process via the second

leakage valve.

The restraint passage of the cleaning liquid provides for a perfect

cleaning of the whole leakage chamber.

- Flushing quantity per CIP cycle: about 1.2 tr / 10 s

- Cleaning pressure at CIP cleaning connection: min. 2 bar

max. 5 bar

Under standard operating conditions, 15 valves DN 25/1” - 100/4”

can be cleaned via one spray distribution line DN 25.

6.3. Cleaning(leakagechamber)

Recommendation of cleaning cycles with standard operating

conditions and CIP liquids.

Cleaning steps CIP-spraying

Pre-flushing 3 x 10 sec.

Caustic flushing 80°C 3 x 10 sec.

Intermediate flushing 2 x 10 sec.

Acid flushing 3 x 10 sec.

Subsequent flushing 2 x 10 sec.

fig.6.2.

CIPIN

CIPOUT

G ⅛

Loading...

Loading...