10

- The maintenance intervals depend on the application of the valve

and should be determined by the operator carrying out regular

visual checks of the valve.

- The double seal butterfly valve possesses only a few wear parts:

disc seal and bush bearings.

- The customer is recommended to hold spare seals and bush

bearings on stock.

For valve maintenance APV supplies complete seal kits including

seal grease (pl. see spare parts lists).

- If damaged seals are exchanged, generally replace all seals and

bush bearings.

- Slightly grease all seals before their installation.

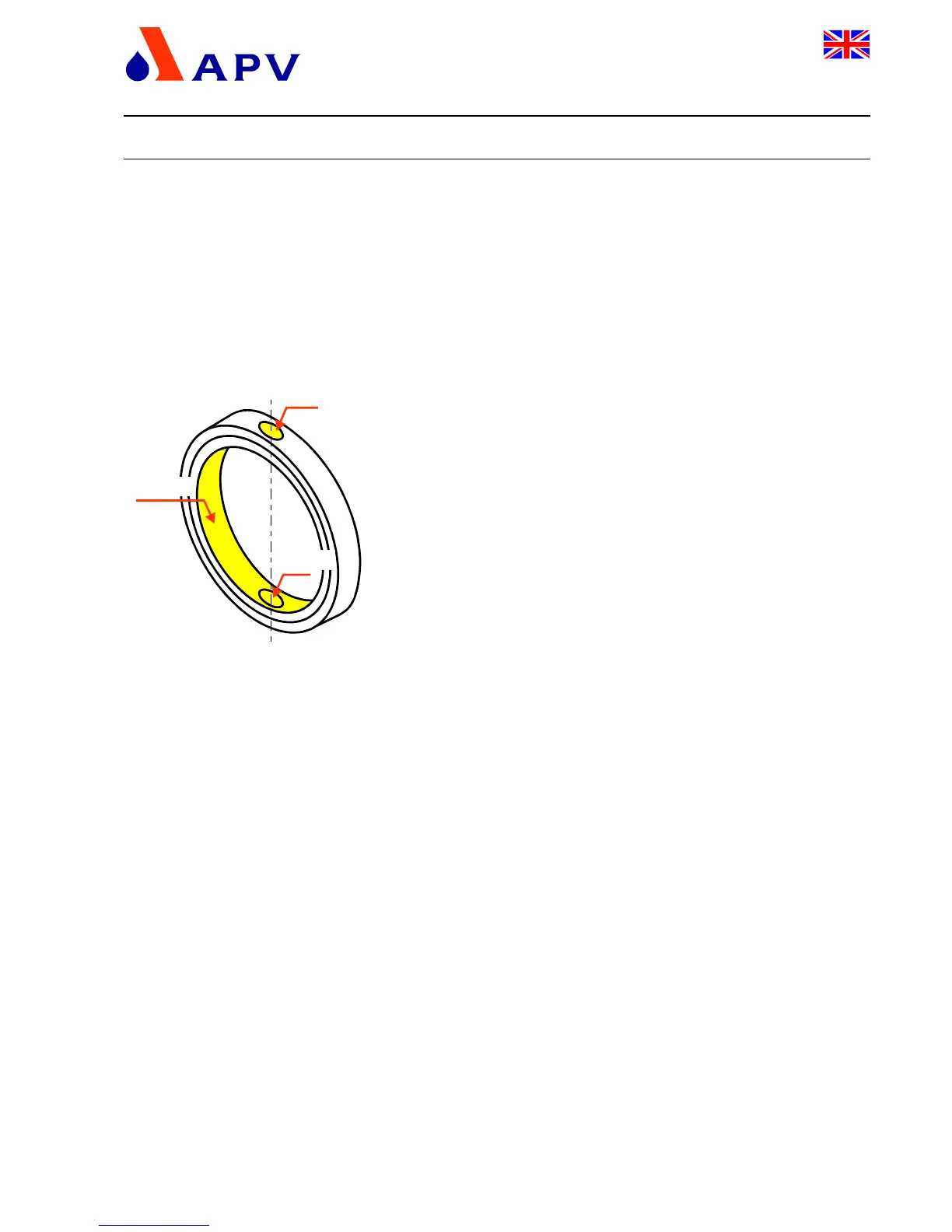

Grease the disc seal according to the illustration - especially the

cross holes.

- Assembly of the valve and change of the valve design FZ

(normally closed) or FO (normally open) according to Service

Instructions.

- Installation of turning actuator according to Service Instructions.

- The inner parts of the turning actuator do not need service.

Attention! Use food-grade grease and special grease being

suited for the respective seal material, only.

Recommendation:

APV-food-grade grease for EPDM and HNBR

(0,75 kg /can - ref. No. 000 70-01-019/93)

(60 g /tube - ref. No. 000 70-01-018/93)

! Do not use grease containing mineral oil for EPDM seals.

grease

grease

grease

disc seal

9. Maintenance

Double Seal Butterfly Valve

DSV

Operating Manual: rev. 2

UK

DSV-UK2.qxp / 10.2005

Loading...

Loading...