6

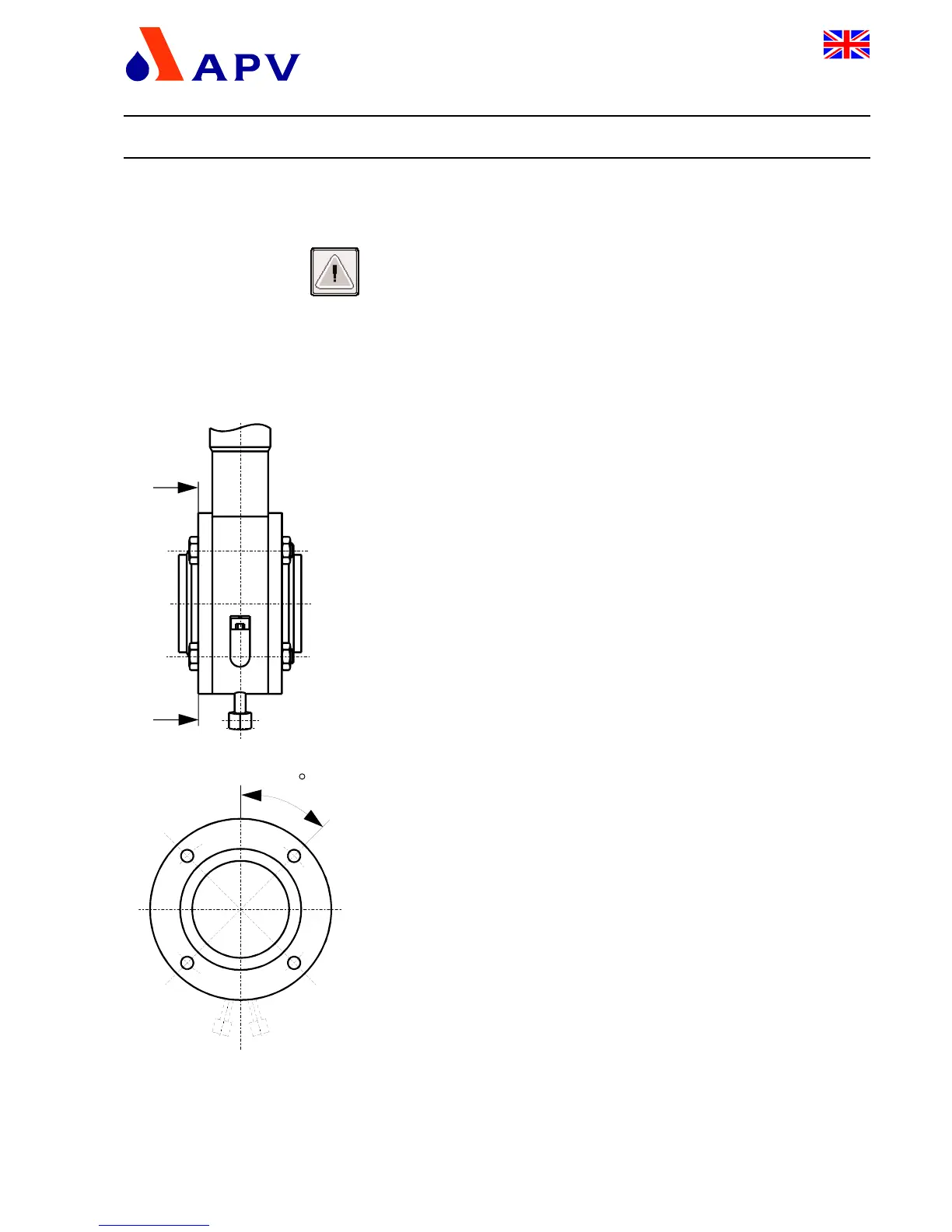

The DSV valve is designed only for the upright installation position

with actuator vertically to the top!

DSV valves are mounted between "flanges-DSV".

Attention: Observe welding instructions.

5.1 Welding Instructions

- Observe the bore position (see fig.) during the welding of the

mating flanges - DSV.

- Welding may only be carried out by certified welders (EN 287-1).

(seam quality EN 25817 "B").

- The welding of the mating flanges must be undertaken in such a

way that deformation strain cannot arise.

- TIG orbital welding is best!

- Before welding, all sensitive parts of the valve must be removed!

Remove the valve core with seals from between the mating flanges.

- After welding of the mating flanges and after work at the pipelines,

the corresponding parts of the installation or pipelines must be

cleaned from welding residues and soiling.

If these cleaning instructions are not observed, welding residues

and dirt particles can settle in the valve and cause damage or be

carried over to other parts of the installation.

- Any damage resulting from the non-observance of these welding

instructions is not subject to our guarantee.

5. Installation

45

Double Seal Butterfly Valve

DSV

Operating manual: rev. 2

UK

DSV-UK2.qxp / 10.2005

Loading...

Loading...