21

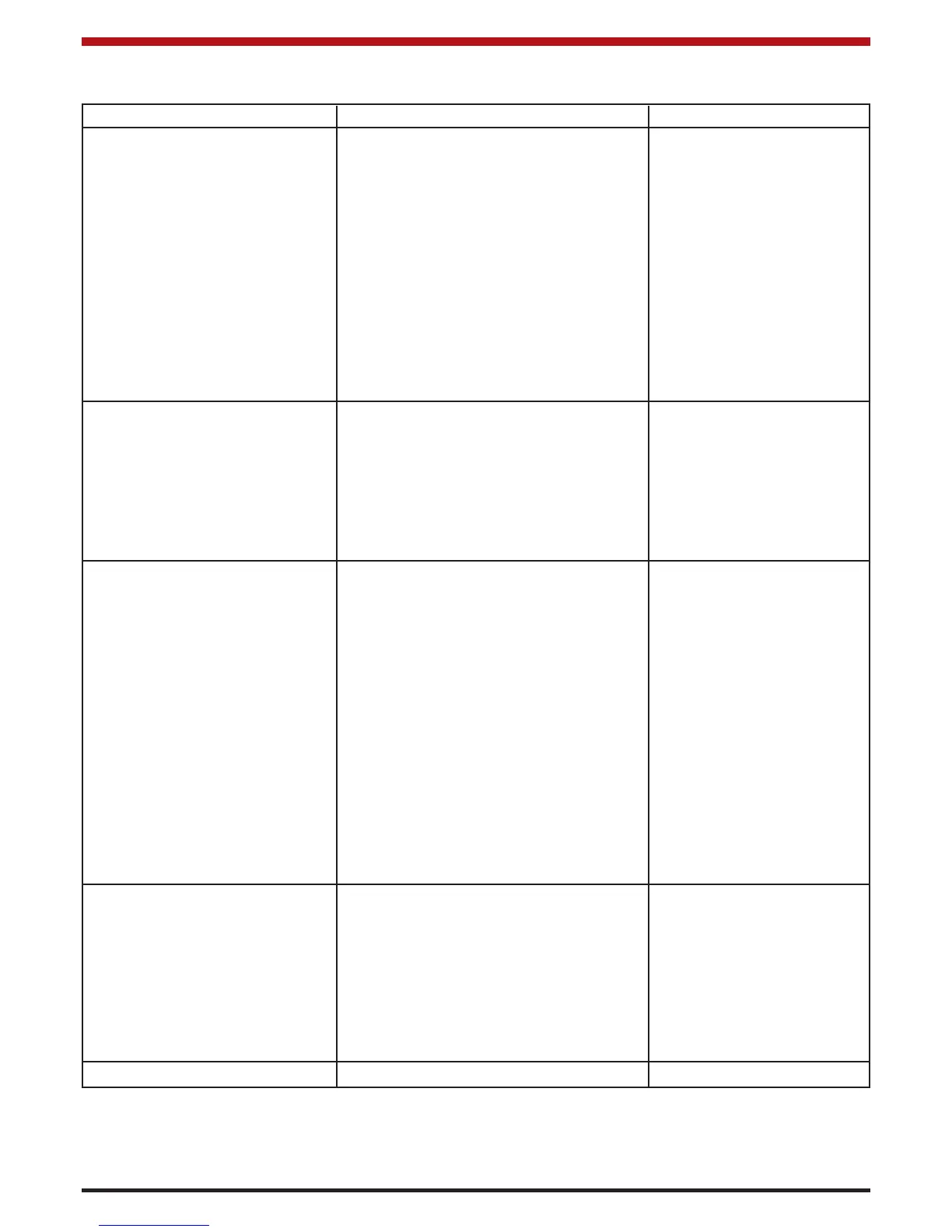

FAULT FINDING

If the stove exhibits any of the following conditions, call your Commissioning Engineer.

PROBLEM CAUSE REMEDY

Stove will not light or goes No Oil in the Tank Fill Tank

out when lighting

Fire Valves off Reset valves, check for

cause of over temperature

Control valve trigger down (off) Reset trigger

Oil feed line filter blocked Free Oil filter

Fuel Line Air Locked Bleed Fuel Line

Carbon Leg Blocked Clean Carbon Leg Assembly

(Stove needs service)

Incorrect Depth of Oil in Burner Increase oil level to 4mm

Base

Down Draught in Flue Fit Anti-Down Draught Cowl

Flames burning under burner Incorrect Chimney Draught Check joint seals, increase

chimney height, adjust flue

bonnet spin valve.

Down Draught in Flue Fit Anti-Down Draught Cowl

Oil level too high in burner base Decrease oil level to 4mm

Oil Rate too high Lower control valve fuel input

rate

Dirty or Unstable Flame, Viewing Incorrect Chimney Draught Check joint seals, increase

Glass sooting up Chimney height, adjust flue

bonnet spin valve.

Incorrect Fuel Input Rate Check Fuel Input Rate, adjust

if necessary

Incorrect Spin Valve Setting Adjust Spin Valve Setting

Shells or Vapour Chamber Lid Ensure all shells are seated

not seated properly on Burner base and that their

seams are staggered.

Lighting Port Open Close Lighting Port

Wrong Grade of Oil Used Only Use Kerosene 28 sec C2

Wicks incorrectly Positioned Ensure that the cut-outs in the

wicks are properly aligned

and that the shells don’t

interfere with the wicks

Oil Smell Apparent Incorrect Chimney Draught Check joint seals, increase

chimney height, adjust the

bonnet spin valve.

Down Draught in Flue Fit Anti-Down Draught Cowl

Incorrect Fuel Input Rate Check fuel input rate, adjust if

necessary

Fuel Leaks Check all fuel pipe connec-

tions, and reseal if necessary.

Cooker Overheating Incorrect Fuel Input Rate Decrease Fuel Input Rate

Loading...

Loading...